06 9月 Foam Ceramic Filter Iceland Aluminum

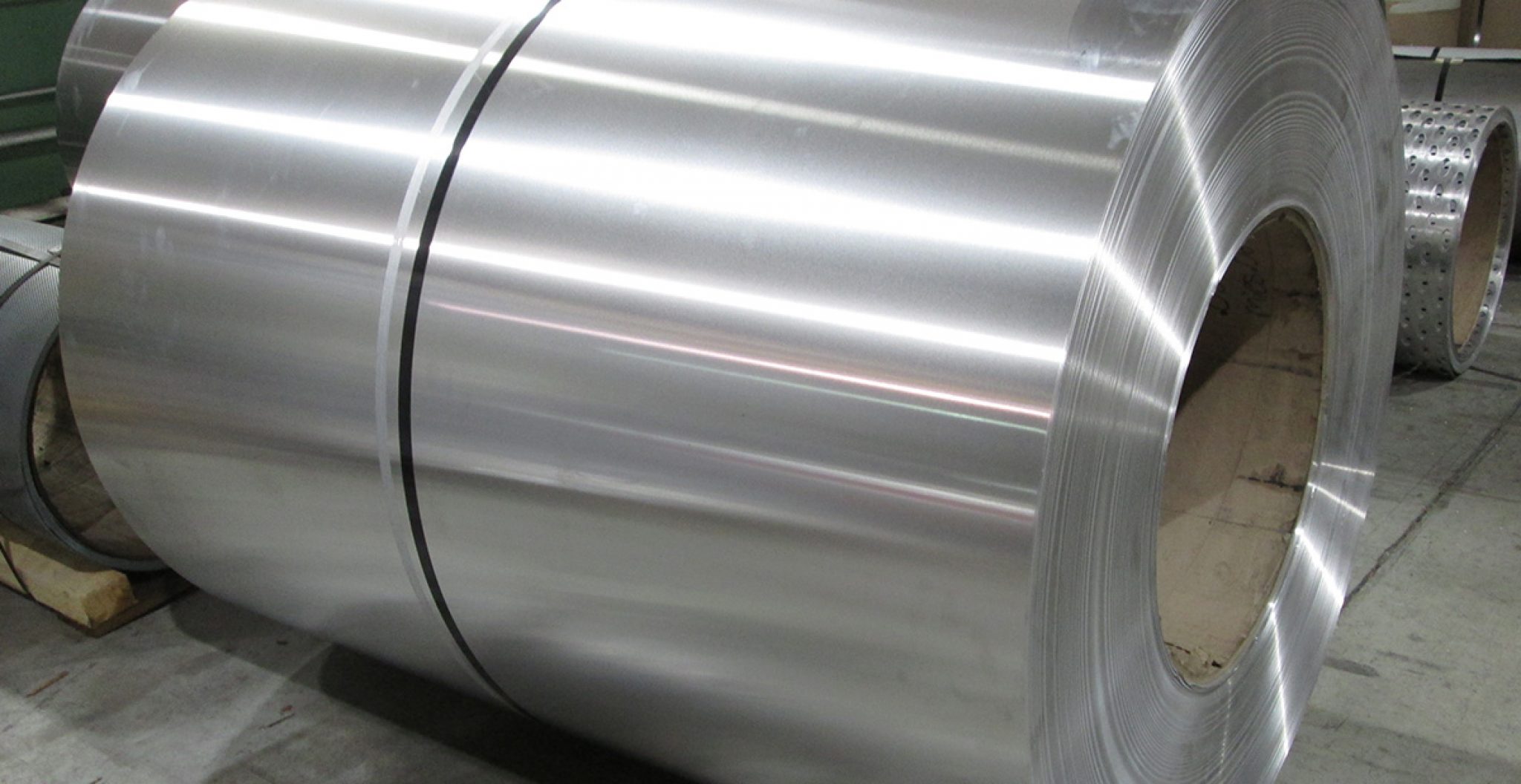

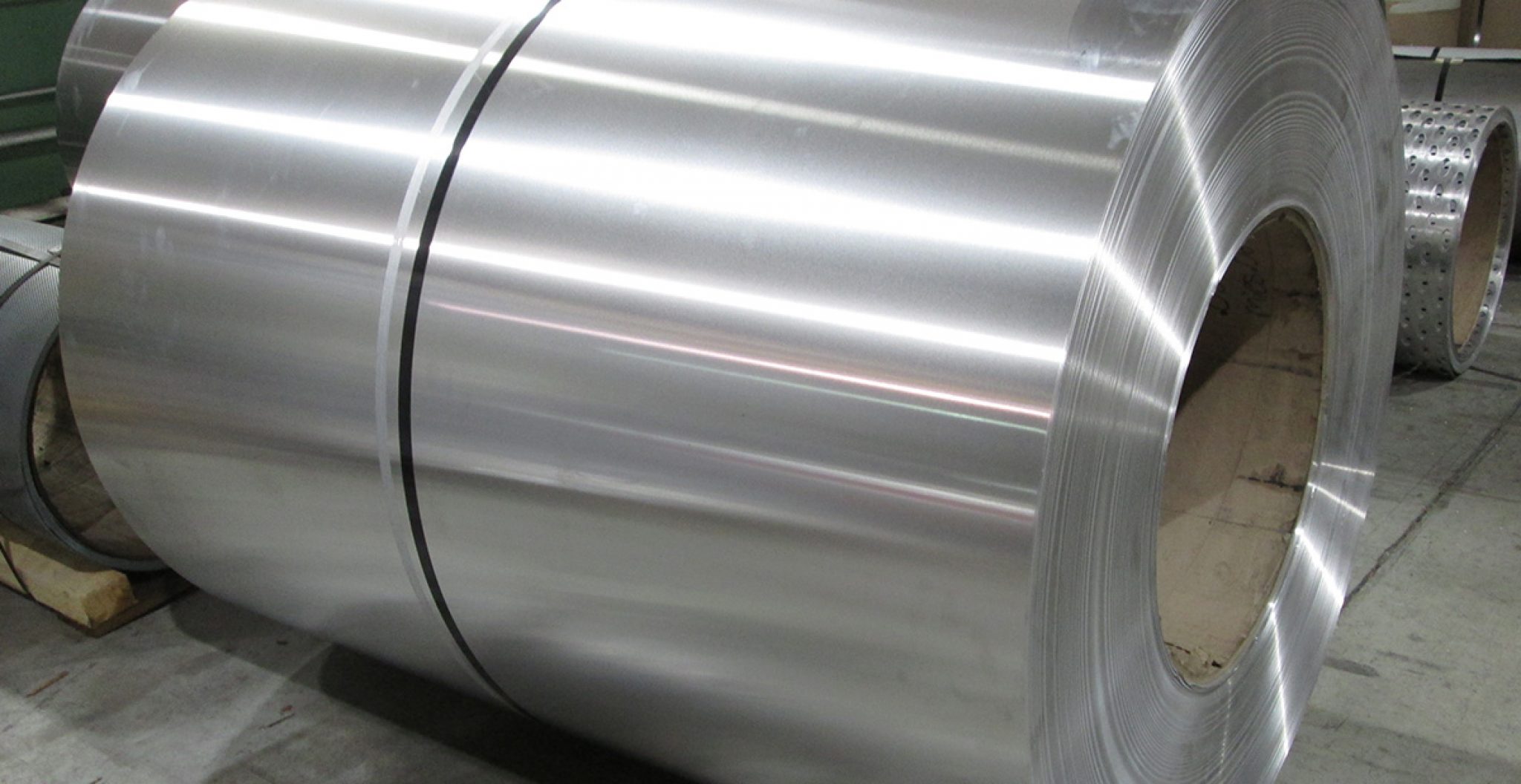

Foam Ceramic Filter Iceland Aluminum is mainly used for the filtration of aluminum and aluminum alloys in foundries and foundries. Clean aluminum melt can produce higher quality castings, less scrap and fewer inclusion defects.

Foam Ceramic Filter Iceland Aluminum has excellent corrosion resistance and corrosion performance of molten aluminum. It can effectively remove inclusions, reduce the trapped gas in molten aluminum, and provide laminar flow to make the filtered metal significantly cleaner.

Cleaner aluminum can produce better casting quality, less scrap and fewer inclusion defects, all of which increase the bottom line.

The ceramic foam filter cleans the liquid aluminum alloy in the casting process by cleaning, reducing or eliminating various non-metallic inclusions and exhaust gas problems in the casting process.

Due to the existence of defects such as non-metallic inclusions in castings, the proportion of casting waste to the total number of castings is even as high as 50-60%.

When various costs increase, the discharge of excess waste may damage the external environment. Inclusion defects not only have a great impact on the mechanical properties and casting performance of the casting, but also have an adverse effect on the cutting and appearance of the casting.

Asian Foundry Filters Seller said that the quality of aluminum melt is very important because it greatly affects the subsequent processing performance and the quality of the final product. Therefore, countries all over the world are very interested in purifying molten aluminum.

There are many reasons for aluminum pollution. On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-melt. Metal-metal slag (such as lining fragments, chlorides, carbides in solder, etc.) and coarse intermetallic particles, etc.

On the other hand, some of the waste materials that make up the cargo will introduce some non-aluminum pollutants in the recycling process.

Because the waste comes from process waste, geometric waste and off-site waste in each process of the facility, the route is different, the composition is complicated, and the quality is poor.

No Comments