11 4月 Filtration mechanism of porous ceramic filter

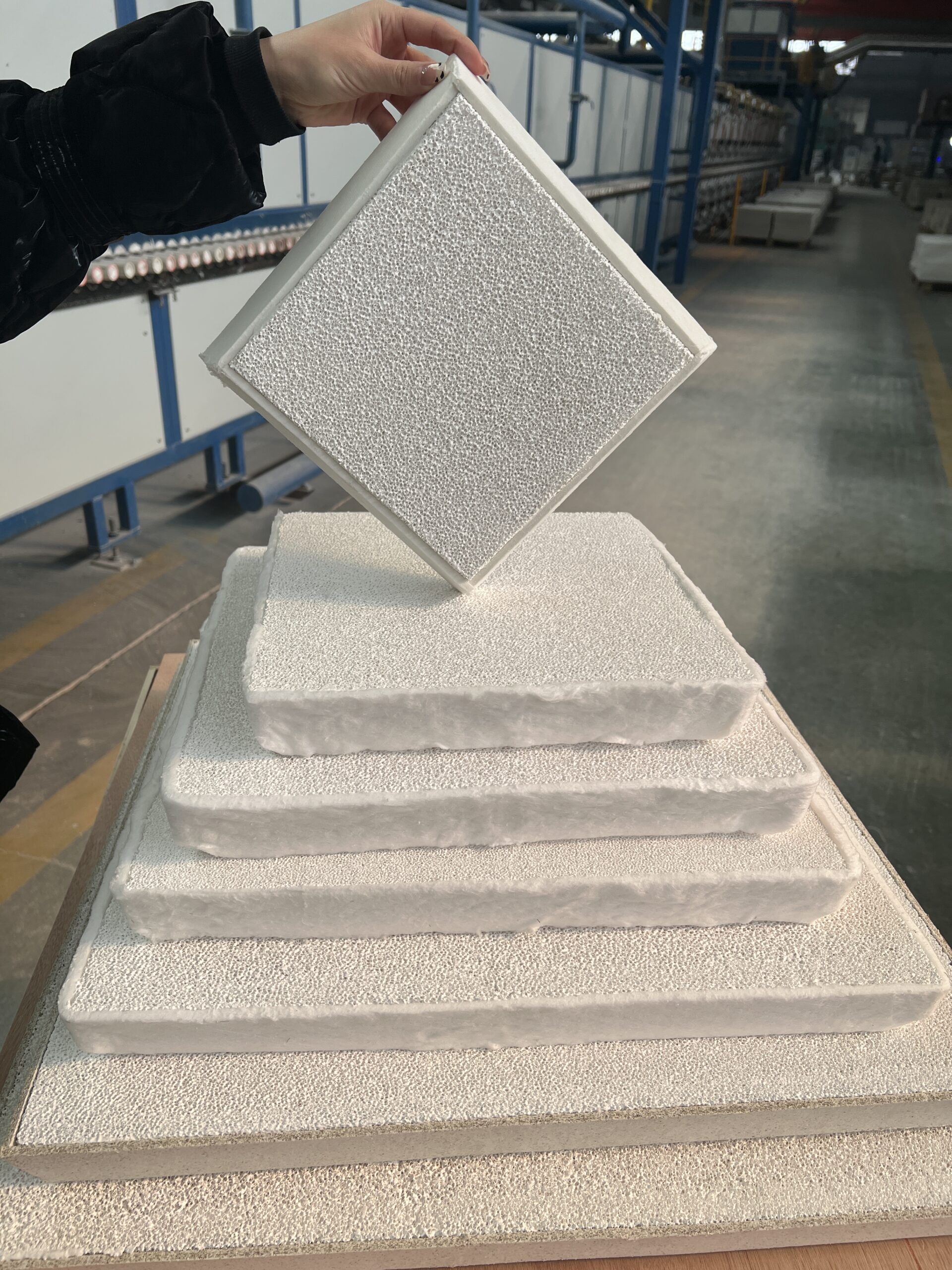

Porous ceramic filter is a porous medium with a three-dimensional through-network structure. It has good chemical stability, high specific strength, high-temperature resistance, thermal shock resistance, and a large specific surface area. It is widely used in the filtration and purification of high-temperature melts in the metallurgical industry. Its filtration The purification mechanism is mainly manifested in several aspects:

1. Screening mechanism: The surface of the porous ceramic filter is equivalent to a layer of the filter screen. When the size of solid impurities in the high-temperature melt is larger than the surface aperture of the porous ceramic filter, the impurity particles will be blocked on the surface of the porous ceramic filter to achieve the filtration of large particles of impurities. purification effect;

2. Sedimentation filtration: When larger particles accumulate more and more, a loose sediment layer is formed, and the melt can still pass through as the thickness of the sediment layer increases, and the particle size becomes smaller and smaller;

3. Deep bed filtration: When the melt flows through the porous ceramic filter, the solid particles in it come into contact with the surface that constitutes the ceramic part of the filter plate, resulting in the particles attaching to the surface in contact with the melt. Due to the tortuous path of the melt flow, there is even a phenomenon of cross-flow return in a small local area, which greatly increases the chance of particles contacting the filter medium, which is conducive to the capture of impurity particles. Whether the particles can be removed depends not only on the collision probability but also on the adsorption capacity of the particles on the surface of the ceramic foam filter in contact with the melt. The stronger the affinity between the material that makes up the filter plate and the inclusion particles, the more microscopic defects or roughness on the surface of the pores will help the adsorption and retention of inclusion particles.

When the high-temperature melt flows through the ceramic foam filter plate, the filtration and purification of solid inclusions are realized through the combination of the above three functions.

porous ceramic filter

No Comments