10 3月 Electric Heated Launder System

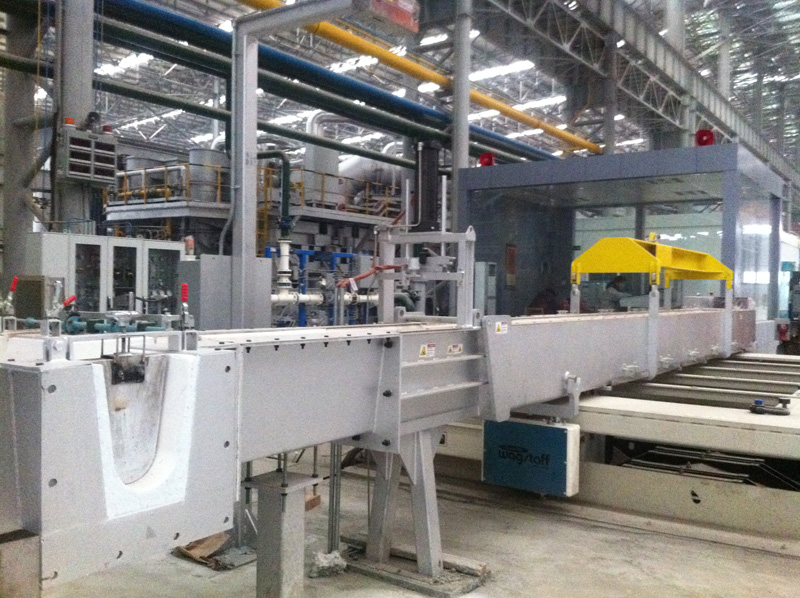

Electric Heated Launder System includes a launder frame; a launder preform set in the launder frame.

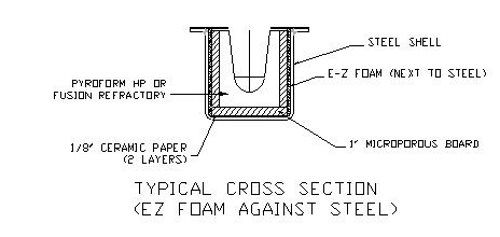

An insulation layer provided between the launder preform and the launder frame.

An electric heating element arranged between the thermal insulation layer and the launder preform.

The Electric Heated Launder System heats the launder through electric heating elements, and controls the temperature at which the launder needs to be heated according to the control and temperature measurement of the electrical system.

Launder System lining is made of high-quality A14 material and is integrally poured in a sintering furnace at high temperature. It has excellent erosion resistance, impact resistance, shock resistance to cold and heat, non-stick aluminum, no chemical reaction with aluminum, and low thermal expansion coefficient. , It maintains a stable appearance at working temperature, does not absorb moisture, does not generate gasification to the aluminum melt, is durable, and does not pollute the aluminum melt.

Under the conditions of use in accordance with the specified process, the temperature drop per meter of the launder is not more than 3 degrees Celsius, and the service life of the lining is not less than 18 months.

The lining of the runner adopts a combined structure, and the lining of the direct current groove is usually 600mm/section. At the same time, elbows and three-way reducers of the same cross-sectional size are provided.

The molten aluminum online purification device is installed between the holding furnace and the casting machine. The molten aluminum comes out of the holding furnace, first flows through the degassing box, and after degassing in the online degassing device, it enters the filter box and is filtered through the foam ceramic plate. After entering the casting machine.

Electric Heated Launder System Instructions

1. Corresponding to the drawing structure, install the runner to ensure that the runner is clean, free from damage and seamless.

2. Uniform preheating of the installed standard launder, heating at a constant speed for 1-2 hours, check that the surface of the lining is red, that is, within 800°C, to remove the adsorbed crystal water, close to the casting temperature, and use it safely and efficiently.

The launder has no electric heating and baking conditions, so it has to be baked with flame.

3. The key is to control the flame temperature. The second is to avoid direct flame grilling to avoid thermal stress caused by local heating to cause the lining to burst. The flame is divided into weak flame (red soft flame), medium flame (yellow), strong flame (blue and white).

The change in the situation of the molten aluminum launder industry will develop with the changes in the market. The business operation and management have changed from a single goal-based development in the past to a systematic and scientific management. How to understand the molten aluminum launder industry from a professional perspective The development of the market and the transformation of the market, how to use scientific methods to effectively manage all levels of the enterprise will become the primary issue for the survival and development of the enterprise in the future.

The operation and management of an enterprise requires systematic and scientific knowledge, which cannot be accomplished overnight. It is simple to implement and use a professional perspective to help enterprises understand the aluminum liquid launder industry, broaden their ideas, clarify their clues, and guide enterprises to find and improve enterprises quickly and effectively. Competitiveness method.

No Comments