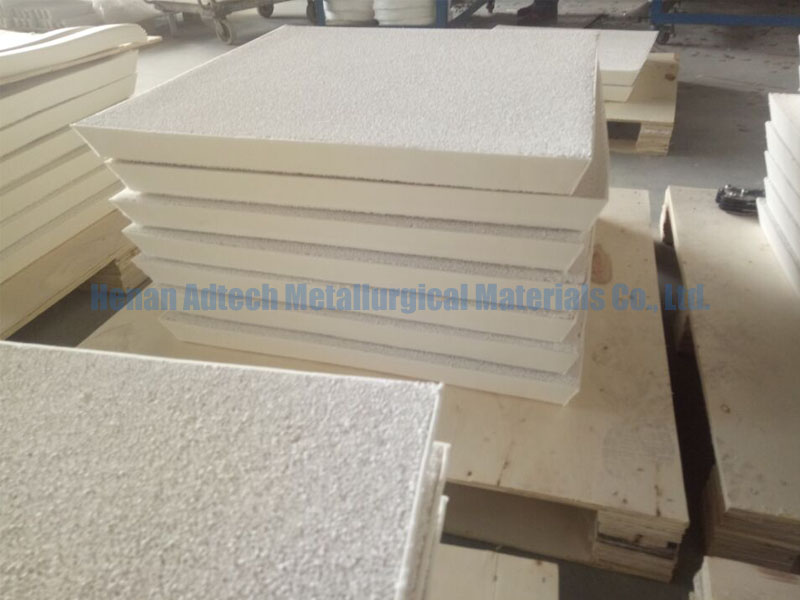

21 2月 China Ceramic Foam Filter Cff

China Ceramic Foam Filter Cff is produced based on a carrier with a solid network structure and organic foam cells, and is used for the filtration and purification of molten aluminum.

The foam filter is put into the thixotropic alumina slurry through an automated production line, and the slurry is dried and solidified and deposited evenly on the foam skeleton of the carrier. Then it is fired at a high temperature of 1180°C to form the final product.

Aluminum has good reflection performance to light, and it reflects ultraviolet rays stronger than silver.

The purer the aluminum, the better its reflection ability. The method of vacuum aluminum coating is commonly used to make high-quality mirrors. Vacuum aluminum plating

The combination of film and polysilicon thin film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain the silver-white luster and is often used to make paint, commonly known as silver powder.

China Ceramic Foam Filter Cff is used to filter impurities in molten aluminum alloy, which helps to meet the production requirements of high value-added, high-tech performance aluminum alloy precision casting parts (such as computer hard disks, PS base plates). Used for printing, canning materials, fan blades of turbojet engines, etc.

The conductivity of pure aluminum is very good, second only to silver and copper. In the power industry, it can replace part of copper as wires and cables. Aluminum is a good conductor of heat. In industry, aluminum can be used to make various heat exchangers, heat dissipation materials, and civil cooking utensils.

Aluminum has good ductility, can be drawn into filaments, rolled into various aluminum products, and can be made thinner than

0.01mm aluminum foil is widely used for packaging cigarettes, candy, etc.

Advantages of China Ceramic Foam Filter Cff

The filter adopts the principle of adsorption, which can effectively remove large inclusions in molten aluminum, and effectively adsorb small inclusions.

No debris falls off, effectively reducing the pollution of molten aluminum.

Excellent thermal shock resistance, improve the erosion resistance of molten metal.

Automated production, 3 calibration procedures, precise dimensions, and tightly installed filter bowls.

Improve surface appearance and performance, purify molten aluminum.

Aluminum alloy has some better properties than pure aluminum, which greatly broadens the application range of aluminum.

For example, pure aluminum is relatively soft. When a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved. It is almost equivalent to steel. It has a low density and is not easy to rust. It is widely used in airplanes, automobiles, trains, and ships. , Satellite and rocket manufacturing.

No Comments