12 3月 Ceramic Foam Filters

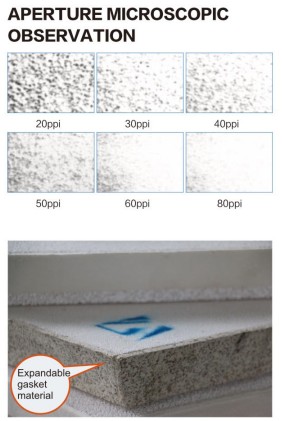

Ceramic Foam Filters range in size from 10 to 80 ppi.

The most commonly used is 20-40 ppi. For industrial foundries, it is necessary to achieve the desired aluminum casting rate and the lowest acceptable filtration efficiency.

The 10-20ppi filter has poor particle retention capacity, and is often used to filter the intercepted particles, surface oxides and other large particles generated during melting, storage and transportation.

High pore density filters with 60-80 ppi are only suitable for quality-sensitive applications, such as critical surface extrusion and thin-sheet products.

The structure of CFF creates a unique, tortuous fluid flow path that captures inclusions and allows for clean, smooth travel of the metal outlet to the mold cavity.

The most important filter parameters are effective porosity (that is, porosity, which effectively causes fluid), tortuosity, specific surface area and pore size.

The filtration process also depends on: alloy type, refiner, pouring rate, metal temperature, etc.

The addition of the refiner before the filter has a particularly negative impact on the filtration efficiency.

Based on cost, ease of use and acceptable performance characteristics, CFF is generally considered to be the “best” filter for casting.

Their main advantages are: high filtration efficiency, reduced turbulence, refractoriness and corrosion resistance, suitable for the most demanding casting applications.

Deep-bed particle filters generally have better filtration performance, but they are more difficult and expensive to operate.

The chemical composition of Ceramic Foam Filters is mainly alumina, and the porosity of the filter is about 85-90%. The density of ceramic particles is 3.48+0.02 g/cm.

Permeability is an important parameter for CFF characterization because it needs to predict the flow rate that can be obtained at a given pressure drop, or to be able to predict the pressure drop required to reach a specific flow rate.

The relationship between these quantities can be expressed as a function of fluid flow and media properties, and is obtained by fitting the permeability equation.

No Comments