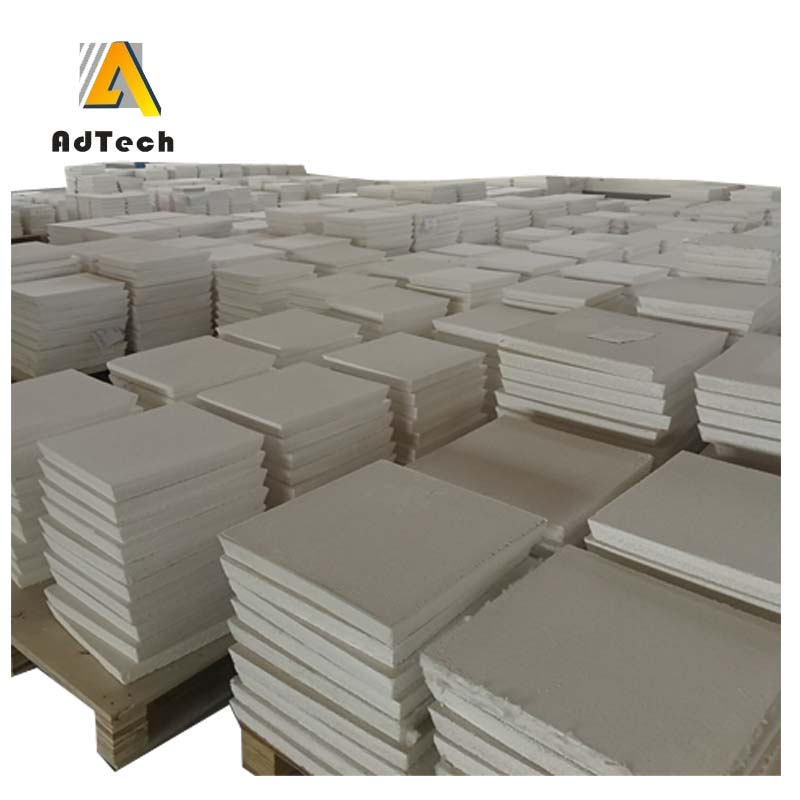

01 4月 Ceramic Filter Material

Ceramic Filter Material can be used for filtering and purifying molten aluminum through this method.

The production process is as follows, the carrier is put into the thixotropic alumina slurry, and the square-centering correction automatic extrusion process is adopted.

The slurry is uniformly deposited in the foam skeleton of the carrier.

After the carrier is dried and solidified, it is fired at a high temperature of 1180°C to form the final product.

The Casting Filter Box is equipped with a filter to filter impurities in the aluminum alloy liquid.

Requirements of Ceramic Filter Material

1. The size specifications must be accurate.

2. Ensure the flatness of the Porous Ceramic Filter.

3. It has accurate porosity, which can be selected according to the filtration accuracy and flow rate, and has a certain degree of air permeability.

4. There is a certain sintering strength as a parameter to measure whether the slag falls.

5. The surface hardness of the filter plate should be high, and a special coating should be applied.

6. The filter plate needs to be cleaned with heat-resistant aluminum liquid. Because the high-temperature aluminum liquid suddenly touches the filter when it is released, 7. Make the filter close to the temperature of the liquid. The filter should have a small linear expansion coefficient. The film must not be washed off and softened.

8. The filter has high chemical stability and does not react with aluminum at high temperatures.

When using Ceramic Filter Material, with the formation of surface deposits, the Casting Filter Box in the filter box can intercept both large particles and small particles.

When the adsorbed particles reach saturation, that is, the number of particles adsorbed by the melt is equal to the number of particles carried away by the melt flow, the slag removal ability decreases. Need to replace a new ceramic foam filter.

The principle of the installation position of the filter plate should prevent the filtered aluminum liquid from turning over and flowing into the crystallizer.

For the horizontal flow channel, since the oxide film in the flow channel is continuous, the installation position of the filter does not have to be very close to the crystallizer.

Before installing the filter, tap the filter to remove the remaining ceramic fragments and remove the fragments in the launder to avoid clogging the filter.

The combination between the installed filter and the launder must not leak.

The metal foam filter in the filter box can intercept large and small particles to form surface deposits.

In addition to considering the actual production quality requirements of aluminum products, the selection of foam aluminum filters must also consider the flow of aluminum in the sink during the casting and rolling, the total amount of filtration, the cleanliness of the aluminum liquid itself, and the production cost.

Choosing filter plates with too high specifications will increase costs and reduce production efficiency.

Research Progress of Liquid Aluminum Filter

Today in 1935, Degussa has developed a filter for filtering light metal alloys

Today in 1940, developed deep bed filters for aluminum, ceramics and petrol coke

Today in 1970, Alcan company developed an aluminum deep-bed filter

Today in 1975, SELEE developed ceramic foam filter

1980-Development of Rigid Media Tube Filter (RMF)

Today in 1990, the development of surface active ceramic foam filter

In 1995, developed a two-stage filter device

2002-Development of small filter equipment (hydropower, aluminum, etc.)

In 2010, Germany launched a multifunctional metal melt filter to contribute to the zero-defect material project…

The goal of future filter development: to remove finer particles, reasonable pressure drop, minimum metal loss, higher filtration efficiency, and more convenient operation.

No Comments