03 6月 Aluminium Scrap 6063 Molten Metal Filtration

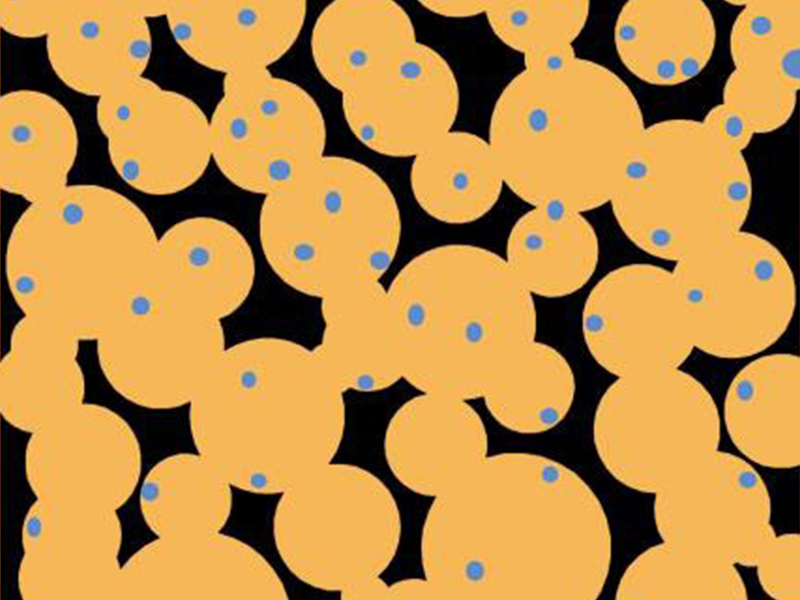

Aluminium Scrap 6063 Molten Metal Filtration is specially developed by AdTech for purifying molten aluminum. The molten aluminum flows through the tortuous and porous three-dimensional foam structure, and the tiny impurities are trapped, adsorbed, deposited, and firmly adhered to the pore walls, filtering out the micron-level impurities in the molten aluminum, and solving the aluminum alloy’s sensitivity to internal defects. Sex.

Alcoa’s factory used 100% scrap to produce 6063 alloy as a control experiment.

It is first carried out according to the traditional melting and casting process, but half of the gold scraps are filtered with foam ceramic filter plates, and the other half are not filtered.

As a result, it was found that a large number of non-metallic inclusions were removed from the aluminum ingot filtered by the ceramic foam filter plate. The extrusion test shows that under the same surface quality, the extrusion speed of the extruded filter wool is increased by 20%, the extrusion force is reduced by 3%, and the overall output should be increased by 15%.

The experiment also shows that the average surface roughness of the profile treated by the foam ceramic filter plate is reduced by about 10% even at a higher extrusion temperature.

In summary, the application of Aluminium Scrap 6063 Molten Metal Filtration can effectively remove various inclusions in molten aluminum, greatly improving the cleanliness of the metal, thereby helping to improve product quality and reduce costs. Productivity has been improved to varying degrees, and the operation is simple, the process is easy to control, does not require excessive investment, and it is worthy of popularization and application.

This product is suitable for all aluminum production departments, including the production of thin plates, strips, foils, rods, tubes, wires, extrusions, forgings, primary aluminum ingots, secondary aluminum ingots, and even continuous casting billets.

Advantages of alumina ceramic foam filter

1. High strength, not easy to drop slag;

2. High open porosity and uniform pore structure;

3. The size of the pores is the same, and the flow rate is stable when the aluminum liquid passes through;

4. There are many varieties, from 7 inches to 26 inches, and the mesh size is 20ppi to 60ppi;

5. Heating, easy to operate, only need to use and replace, without damaging the inner lining of the filter box;

6. Fireproof cotton and expanded cotton edge can be provided.

No Comments