01 7月 Aluminium Karachi Ceramic Foam Filter

Aluminium Karachi Ceramic Foam Filter is mainly used in the purification process for the production of aluminum and aluminum alloys. With the continuous improvement of the quality requirements for aluminum products, the application of alumina ceramic foam filters will become more and more extensive.

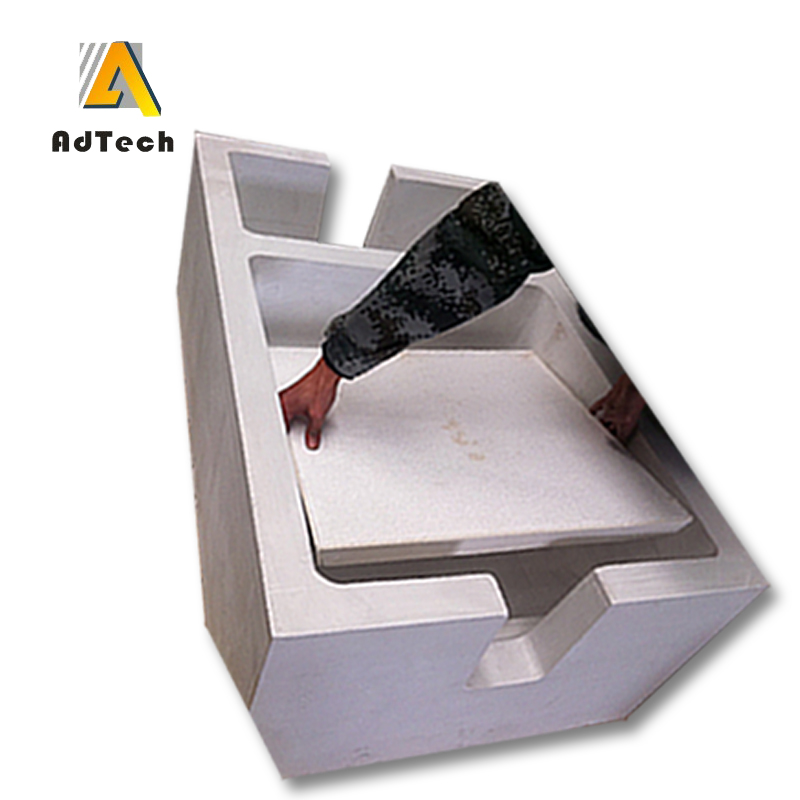

The ceramic foam filter Al2O3 is specially designed for cast metal. This is because a “filter cake” is formed on one side of the intake filter, and because a deep filter is formed inside the ceramic matrix.

Japan Aluminium purchases through sales@adtechamm.com for casting aluminum flux filtration equipment for continuous casting and semi-continuous casting.

The technicians of Japan Aluminium believe that in the casting process, the ceramic foam filter is an effective tool to achieve the metallurgical purity of the molten metal. The filter can also stabilize the filling of the mold, thereby preventing defective castings from appearing.

The Aluminium Karachi Ceramic Foam Filter is no longer a three-dimensional network structure, but a pipe with twists and turns connected to each other with uneven thickness.

It is precisely this uneven tube wall that plays a key role in capturing small inclusions in the aluminum melt. This is the same as the filtration mechanism of deep bed filtration.

This structure also increases the path through which the aluminum melt is in contact with the ceramic part of the filter plate, thereby increasing the probability of inclusion particles being adsorbed.

It seems that a perfect three-dimensional network structure can facilitate the passage of aluminum melt but may not have a good slag removal effect.

Evaluation of the pros and cons of the filter plate should start from the filter mechanism and consider its comprehensive performance rather than one item.

Aluminium Karachi filter for CFF unit is a new type of high-silicon smelting manufacturing technology with long furnace life. It is mainly used for high value-added and high-tech performance aluminum production that requires smelting and purification, replacing the high-cost ceramic tube filtration in the industry. Equipment and ordinary plate filter equipment products, use this plate filter and related technical guidance to effectively filter the barrier to produce the trace impurities of aluminum products to meet customer needs.

Ceramic Foam Filter, Ceramic Filter For Foundry, Alumina Ceramic Foam Filter are used in many country aluminium melting workshop, such as Philippines,Cambodia,Laos,Malaysia,Myanmar,Thailand,Brunei,Vietnam,Singapore,Indonesia,Pakistan,Bhutan,Maldives,Bangladesh,Nepal,SriLanka,India,Kazakhstan,Kyrgyzstan,Tajikistan,Uzbekistan,Turkmenistan,Kazakhstan,Kyrgyzstan,Tajikistan,Uzbekistan,Turkmenistan

No Comments