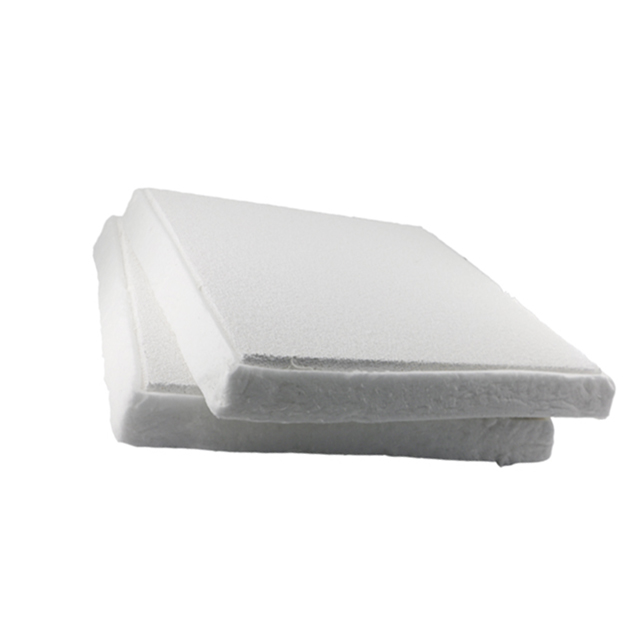

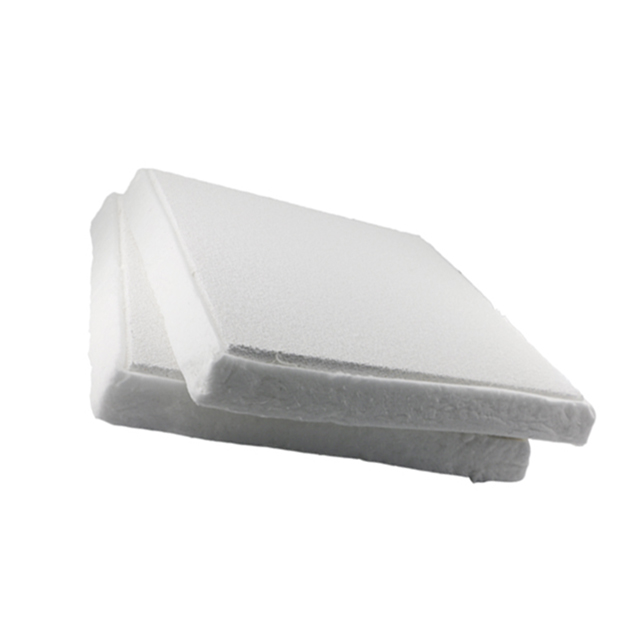

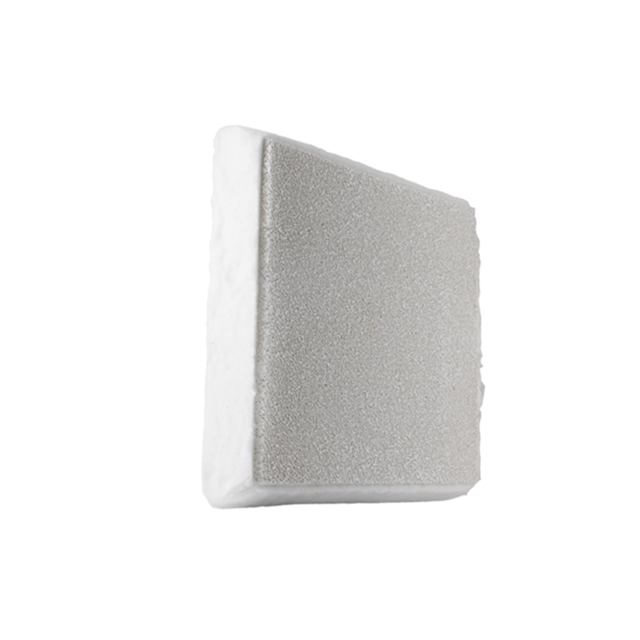

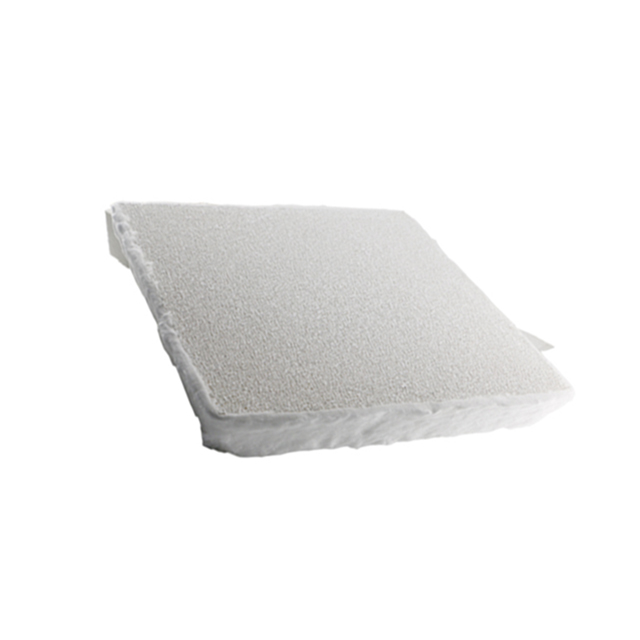

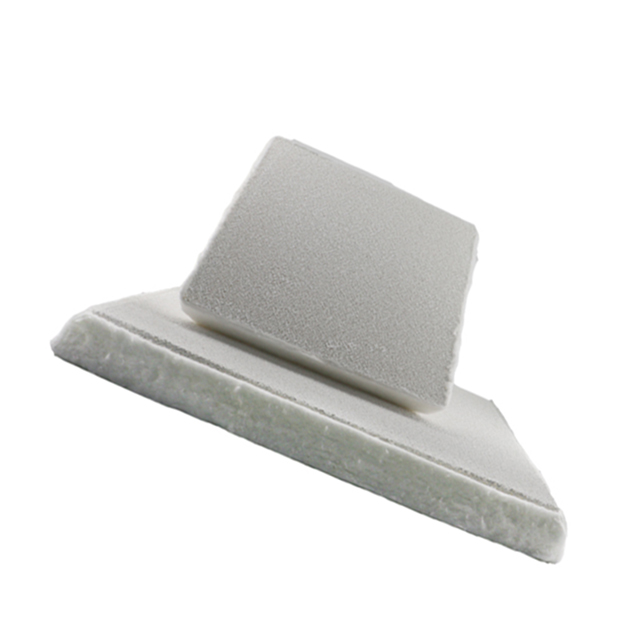

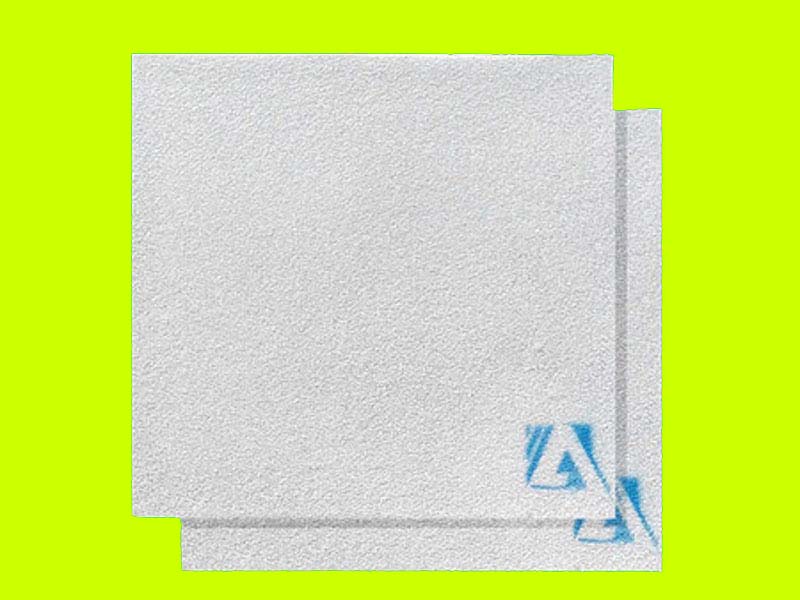

11 Dec Buy Asian Foundry Filters

Buy Asian Foundry Filters for the purification of aluminium casting process in the casting factory. Eliminates turbulence in the metal stream, Smoothes out metal flow, avoiding sprays, splatter and backset. Improve fluidity, castability, machinability, yield and cost-effective. Buy Asian Foundry Filters It can effectively remove large inclusions in...