26 Mar Ceramic Foam Filters For Foundry

Ceramic Foam Filters For Foundry specialize in producing high-quality cast products for aluminum casting workshops, reducing waste due to impurities, reducing costs due to impurity defects, achieving faster extrusion or hot rolling speeds, increasing productivity, and alloy replacement Simple, increase casting flexibility, no need to retain metal.

High-Performance Ceramic Foam Filters for Foundries

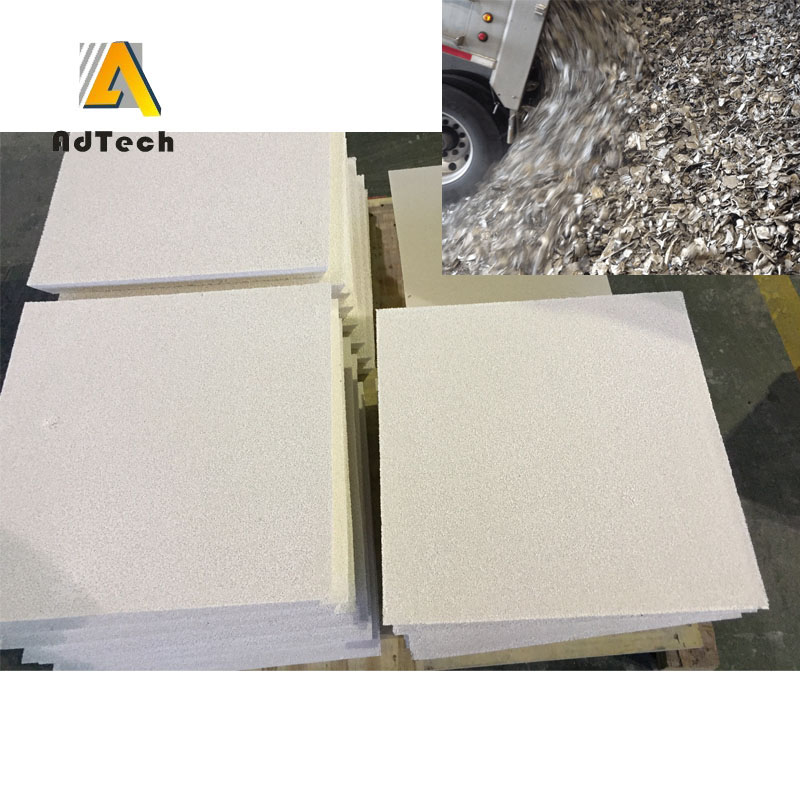

As a global leader in molten metal filtration, AdTech specializes in manufacturing premium Ceramic Foam Filters for foundries looking to eliminate inclusions and improve casting quality. Our advanced filtration solutions are designed to withstand extreme thermal shock and provide a stable laminar flow for Aluminum, Iron, Copper, and Steel casting processes.

Whether you are operating a continuous casting line, gravity casting, or low-pressure die casting, our filters ensure that your final products meet the highest metallurgical standards.

Alumina Ceramic Foam Filter for Aluminum Foundry

Why Top Foundries Choose AdTech Ceramic Filters

Foundries worldwide rely on AdTech because we don’t just sell filters; we provide filtration solutions that reduce scrap rates. Our ceramic foam filters are engineered with a unique 3D open-pore structure that effectively removes micron-sized impurities.

- Superior Filtration Efficiency: Removes non-metallic inclusions (oxides, slag, dross) from molten metal.

- Reduced Turbulence: Converts turbulent metal flow into a smooth laminar flow, preventing air entrapment and mold erosion.

- High Thermal Shock Resistance: Stable performance at temperatures ranging from 1100°C to 1700°C, depending on the material.

- Customized Specifications: Available in various shapes (square, round, geometric), sizes (from 7 inches to 26 inches), and pore densities (10 PPI to 60 PPI).

Product Specifications & Types

We offer a complete range of filters tailored to specific metal alloys. Choosing the right material is critical for ceramic foam filter foundries aiming for zero-defect casting.

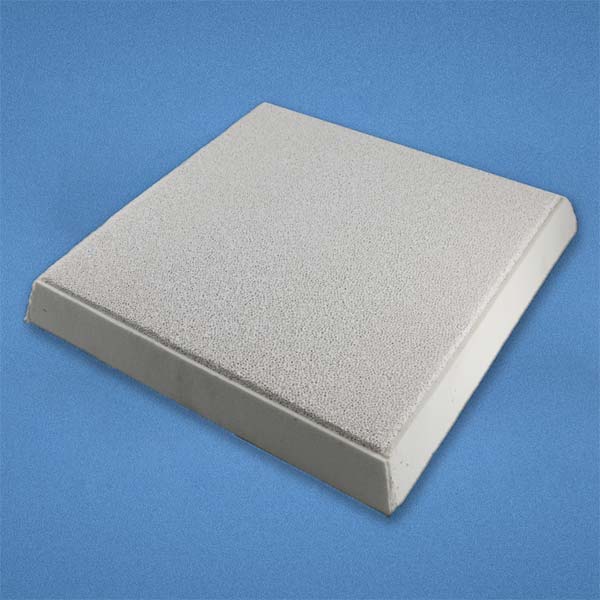

1. Alumina Ceramic Foam Filters (Al₂O₃)

- Application: Primarily for Aluminum and Aluminum Alloy filtration.

- Temperature: Up to 1100°C (1200°C short term).

- Key Features: Excellent resistance to molten aluminum attack. Widely used in aluminum casthouses for ingots, billets, and foil production.

- Gasket Options: Available with or without expandable gaskets to ensure a tight seal in the filter box.

porous ceramic filter

2. Silicon Carbide Ceramic Foam Filters (SiC)

- Application: Ideal for Iron (Grey Iron, Ductile Iron) and Copper casting.

- Temperature: Up to 1500°C.

- Key Features: High strength and excellent thermal conductivity. Perfect for reducing sand inclusion and gas defects in iron castings.

3. Zirconia Ceramic Foam Filters (ZrO₂)

- Application: Designed for Steel and Stainless Steel casting.

- Temperature: Up to 1700°C.

- Key Features: Extremely high refractoriness and strength. Used in high-end casting applications like aerospace and automotive components.

| Specification | Alumina (Al₂O₃) | Silicon Carbide (SiC) | Zirconia (ZrO₂) |

| Color | White / Pink | Grey / Black | Yellow / Off-white |

| Max Temp | 1100°C | 1500°C | 1700°C |

| Pore Size (PPI) | 10, 20, 30, 40, 50, 60 | 10, 20, 30 | 10, 20, 30 |

| Best For | Aluminum Foundries | Iron/Copper Foundries | Steel Foundries |

Installation & Usage Guide for Foundries

To maximize the performance of ceramic foam filters in foundry operations, correct handling and installation are essential:

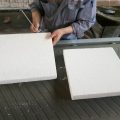

- Preparation: Clean the filter box thoroughly to remove any old slag or debris.

- Placement: Gently place the filter plate into the filter bowl. If using a gasket, ensure it is pressed firmly to prevent molten metal from bypassing the filter (short-circuiting).

- Preheating: We recommend preheating the filter and filter box evenly to a temperature close to the molten metal. This removes moisture and reduces thermal shock during the initial pour.

- Pouring: Maintain a steady pouring height to minimize turbulence. The filter will naturally regulate the flow rate.

Hindalco Industries introduces the installation steps of Ceramic Foam Filters For Foundry

1. Take out the Ceramic Foam Filter

2. Clean the filter box.

3. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing by.

4. Evenly preheat the filter box and the filter plate to make it close to the temperature of the molten aluminum, preheat to remove water, and facilitate the initial instant filtration. The preheating can be implemented by electric or gas heating, and it takes about 15% under normal circumstances. ~30 minutes.

5. Pay attention to the change of the aluminum hydraulic head when pouring. The normal initial pressure head is 100~150mm. When the aluminum liquid starts to pass, the pressure head will drop below 75~100mm, and then the pressure head will gradually increase.

6. In the normal filtering process, avoid knocking and vibrating the filter plate, and at the same time make the launder full of molten aluminum to avoid too much disturbance of the molten aluminum.

7. After filtering, take out the filter plate in time and clean the filter box.

20PPI Ceramic Foam Filters For Foundry

How to use Ceramic Foam Filters For Foundry

1. The position of the filter is as close to the casting as possible to achieve the best filtering effect. Generally, an open gating system is used.

2. Filter area

The cross section of the runner where the filter is placed must be enlarged, generally 2~4 times the normal cross section of the runner, the width of the filter support table is 5~12mm, and the gap between the filter and the filter seat is 0.5~1mm.

3. When multiple filters are used for large castings, the amount of molten iron flowing through each filter must be balanced.

4. The height of the buffer before and after the filter or the upper and lower buffers is recommended to be 1.5H~2.5H (H is the thickness of the filter) to prevent partial overload of the filter.

5. When directly impacting the filter, the pouring height should not exceed 300mm, and it is unavoidable to thicken the filter properly when directly impacting.

6. New product design filters can only be put into mass production after initial test and small batch verification without abnormalities.

Precautions for the use of Ceramic Foam Filters For Foundry. Ceramic Filter Manufacturers introduce that.

1. The filter is ceramic and must be handled with care to prevent bumps;

2. The debris inside the filter must be blown out before putting it into the filter seat;

3. After putting in the filter seat, check that the top surface of the filter cannot be higher than the parting surface;

4. When the casting temperature of steel castings is low, the zirconium filter needs to be preheated.

Storage and shelf life of ceramic foam / straight hole filter

1. Store in a dry and ventilated place, free from rain and heavy pressure;

2. The handling process should be handled with care to prevent bumping and stepping;

3. The shelf life is three years. If the storage period is more than one year, it is recommended to use after drying.

Contact AdTech – Your Partner in Casting Filtration

Are you looking for reliable ceramic foam filter manufacturers? AdTech provides consistent quality, competitive pricing, and technical support to foundries globally.

No Comments