28 Jun Ceramic foam filter for casting aluminum

Ceramic foam filter for casting aluminum

Two series of ceramic foam filters for casting aluminum:

– series for continuous casting of aluminum with direct cooling (DC casting)

– and for casting aluminum in the mold, a shaped casting

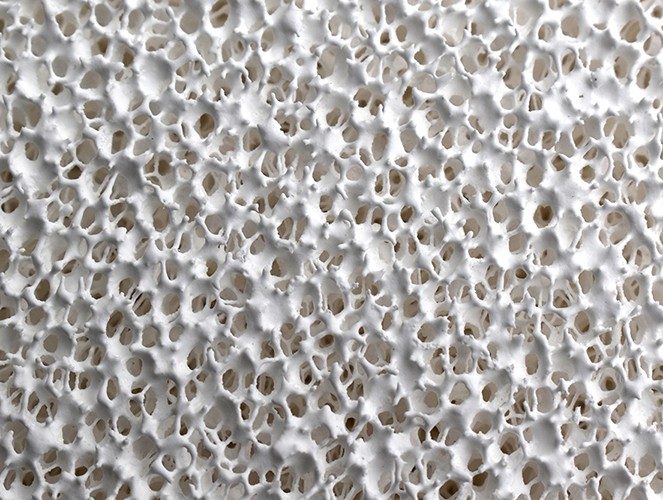

Al2O3 ceramic foam filter – standard filter

Special filter type with increased efficiency and capacity (higher open porosity is achieved, i.e., the filter has fewer clogged pores inside the filter)

Sizes:

10 ” … 26 ’’ (production of the filter under the Customer is possible)

Porosity, PPI: 10 … 70

Bending Strength: approx. 1.5 MPa

The density of the material: 2.2 g. / cm3

Operating temperature: + 1000 – 1200 оС

Main advantages of the filter:

Uniform pore structure

High surface strength (less “snow” in the package)

High operating temperature, up to 1150 ° С

High chemical inertness to reagents. used in a foundry and k. aggressive aluminum melts (8xxx alloy)The

The ceramic foam filter has been successfully used for casting aluminum. Ceramic foam filter for casting aluminum can be used to cast all common aluminum casting alloys.

The ceramic foam filter is made of quartz-based material using silica as a binder, has a density slightly lower than that of liquid aluminum (lower by 0.4 g / cm3), i.e., the filter is always on the surface of the liquid metal.

Authoritative reference

Main technical data of the filter:

Filter size: 40 * 40 … 100 * 100 mm (round – D40 … D100 mm)

Porosity, PP: I 10 … 30

Thickness: 22 (15) mm

Special shapes and sizes are available to order.

Adtech provides these products for the Aluminum Casting Industry – www.adtechamm.com – sales@adtechamm.com

Adtech provides these products for the Aluminum Casting Industry – www.adtechamm.com – sales@adtechamm.com

Online Degassing Unit Ceramic Foam Filter Plate-Type Filtering Unit

Sorry, the comment form is closed at this time.