10 Jun Liquid aluminum purification and sustainable development in aluminum deep processing

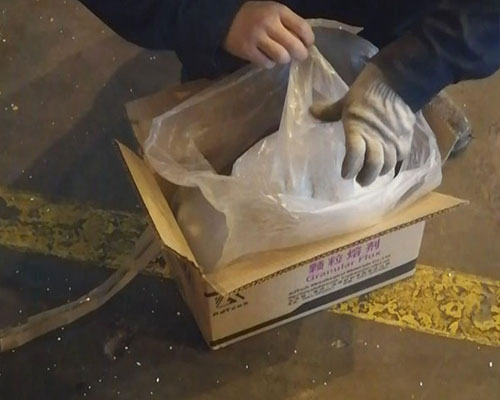

Liquid aluminum purification Q1: Why does liquid aluminum need to be degassed and filtered before deep processing? A1: Liquid aluminum is easily mixed with hydrogen (mainly from water vapor decomposition) and non-metallic inclusions (such as oxides, slag, etc.) during smelting and transportation. These impurities will cause defects...