18 11月 Sell Ceramic Filter Price

Sell Ceramic Filter Price is fair, stable quality and large output. Please visit www.adtechamm.com or contact sales@adtechamm.com.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the aluminum metallurgical material.

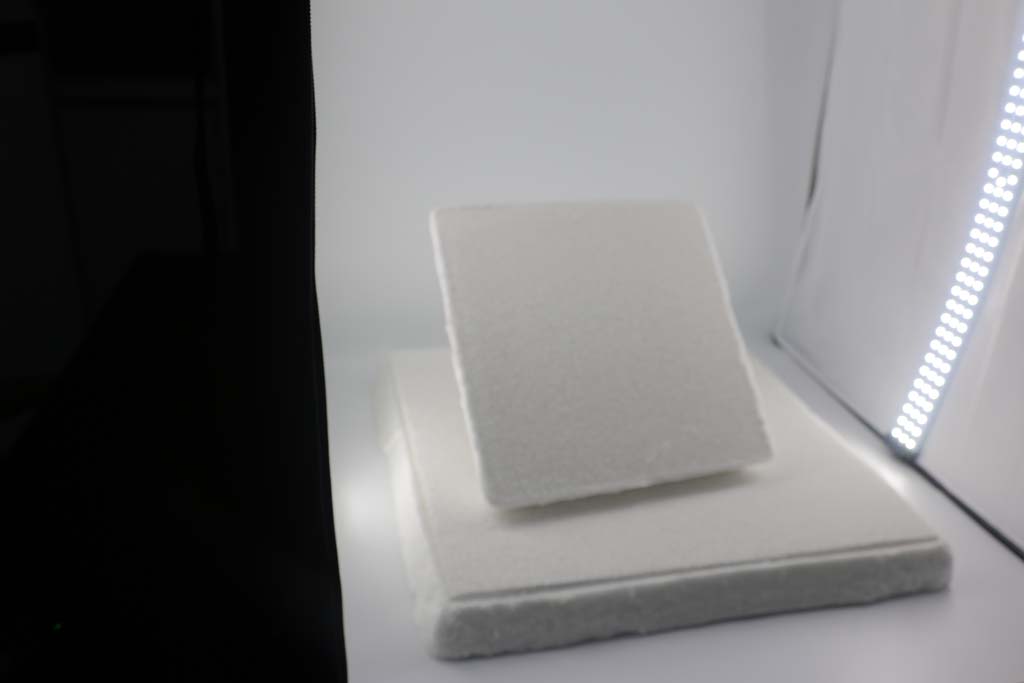

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

Alumina ceramic foam filter plate for purifying molten aluminum can effectively remove large inclusions in molten aluminum and absorb micro-sized particles of small inclusions, which can improve surface quality, product performance, and microstructure. Improve the rate of finished products, widely used in the production of aluminum profile, aluminum foil, aluminum alloy and other production fields.

The scour-resistant movable runner is used between the on-line degassing filter equipment and the casting and rolling mill. It has dual functions: conveying and heat preservation, with repetitive or multiple-used linings, using new high-silicon molten material molding technology, and a certain degree of corrosion resistance Power, non-stick aluminum, non-polluting to molten aluminum.

Mainly used for precision casting and rolling of medium and micron aluminum foil wool, PS plate base for printing and other aluminum alloy products.

The plate filter box equipment has an ultra-long life furnace body and adopts a new high-silicon melting manufacturing technology. It is mainly used for the production of aluminum products with high added value and high technical performance. Melt purification is required to replace the high-cost ceramic tube filter in the industry. Equipment and ordinary plate filter equipment products.

Using this plate filter and related technical guidance, the aluminum products produced can effectively filter and block micron impurities to meet customer needs.

The filter box includes a feed tube, a box body and a foam ceramic filter plate. A flow channel is formed in the box body, and an electromagnetic heating device is wrapped around the feed tube.

The filtering effect of liquid aluminum is good. The foam ceramic filter plate of this structure reduces the flow rate of liquid aluminum, forming liquid aluminum without impact on the filter plate, has a longer service life, and oxides are not easy to accumulate, and can eliminate the liquid aluminum Bubbles.

Sorry, the comment form is closed at this time.