10 4月 Rusal Degassing Equipment

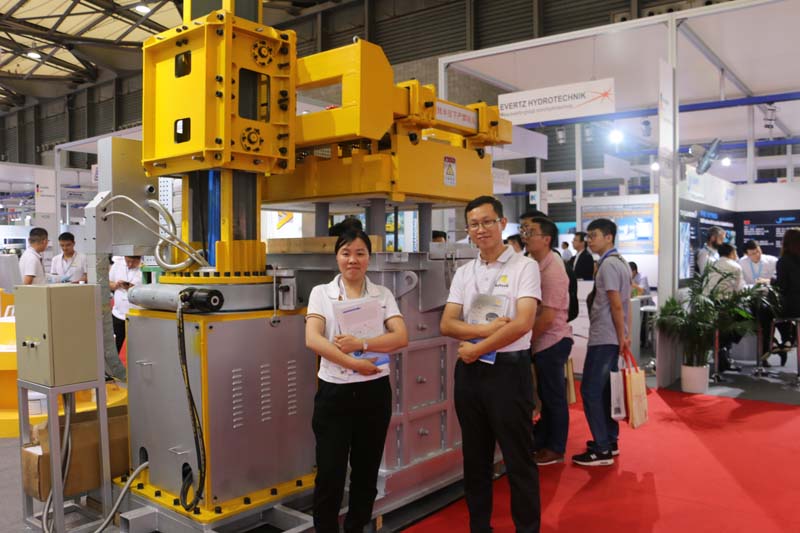

Rusal Degassing Equipment

The United Company was formed by the merger of RUSAL (Russkiy alyuminiy) (Russian: Русский алюминий), SUAL, and the alumina assets of Glencore, completed in March 2007. According to its own statistics, UC Rusal accounts for 6.2% of the world’s primary aluminium output and 6.5% of the world’s alumina production, while operating assets in 13 countries over five continents, employing over 61,000 people across its international operations and offices.

Rusal Degassing Equipment With Nitrogen is stirred by a controlled rotating graphite shaft and a rotor, and the metered inert gas is pressed into the aluminum liquid through the rotor and dispersed into fine bubbles, which are uniformly dispersed in the liquid metal, and the gas partial pressure of the bubbles is zero.

Since the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, and inertness of useless hydrogen and some non-metallic inclusions adheres. The gas bubbles float up to the surface.

When there is a special degassing filter box, these impurities are isolated before the pouring, and then the desulfurization and deoxidation inclusions are achieved by the slag, and the degassing principle is also recognized, and the efficiency is high.

It does not affect the production process, can improve the purity of aluminum liquid in a short period of time, reduce the scrap rate, improve production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products.

Rusal Degassing Unit Performance

It is mainly used for the hydrogen (H) and slags removal from molten aluminum.

It takes gas flotation principle. The rotor takes inert gas or mixture of chlorine and inert gas into molten aluminum and smash the gas into dispersed tiny bubbles, the bubbles rise to molten aluminum surface and finish the below stated procedures at the same time:

In the Rusal aluminum industry, the aluminum liquid Rusal Degassing Equipment and other equipment are installed with a plurality of diffusing gas permeable bricks, and an inert gas such as nitrogen or argon is blown.

The aluminum liquid is turned over, the impurities are floated, and the hydrogen is greatly dehydrogenated, which can greatly improve the quality of the aluminum alloy.

Using this bottom breathable refining technique, the bubbles have no dead ends, small and numerous. Rolling up and down, uniform aluminum liquid temperature, aluminum alloy performance is greatly improved, and achieved good economic benefits.

The device has a simple structure, does not pollute the aluminum liquid, and has low use cost, long service life and simple maintenance. It is widely used in the casting of aluminum alloys in China.

Rusal Degassing Unit from AdTech China(sales@adtechamm.com) which is an enterprise specialized in new material development and high precision online degassing unit production since 2012, got positive feedback from domestic and overseas market.

No Comments