18 1月 Rotary Degassing Machines

Rotary Degassing Machines

The degassing of aluminum is based on the principle that dissolved hydrogen gas will move from an area of high concentration (in the melt) to an area of low concentration (in the inert gas). Hydrogen gas disperses in molten metal as it would if it were released in any confined space. It will maintain a constant concentration throughout the melt. Hydrogen gas can migrate in liquid metal almost as fast as it can in air. Therefore, it is unnecessary to bring every ounce of metal in contact with the inert gas. The efficiency of aluminum degassing is determined by two factors, the transfer rate across the metal/gas interface and the total surface area available for transfer.

When melting aluminum scrap, the process of removing excess hydrogen is essential to producing quality aluminum castings.

Hydrogen is introduced by moisture. Excess hydrogen has a negative effect on the mechanical properties of finished aluminum by creating porosity and overall shrinkage. It is important to remove excess hydrogen during the melting and pouring process.

Introducing inert gases such as argon or nitrogen into the molten metal can be used to remove hydrogen. As inert gas bubbles move up through the molten aluminum, hydrogen diffuses into the inert gas bubbles and essentially disappears. Traditional degassing systems limit mixing, especially at the bottom, where higher speeds are required which results in more surface turbulence. Bubbles are larger and degassing takes longer to achieve desired results. Melters desire superior bubble shearing and dispersion, longer bubble retention time in the metal, complete molten metal circulation, a non-clogging rotor, and to be more thermal shock resistant. Plus they would prefer to use less inert gas in the process.

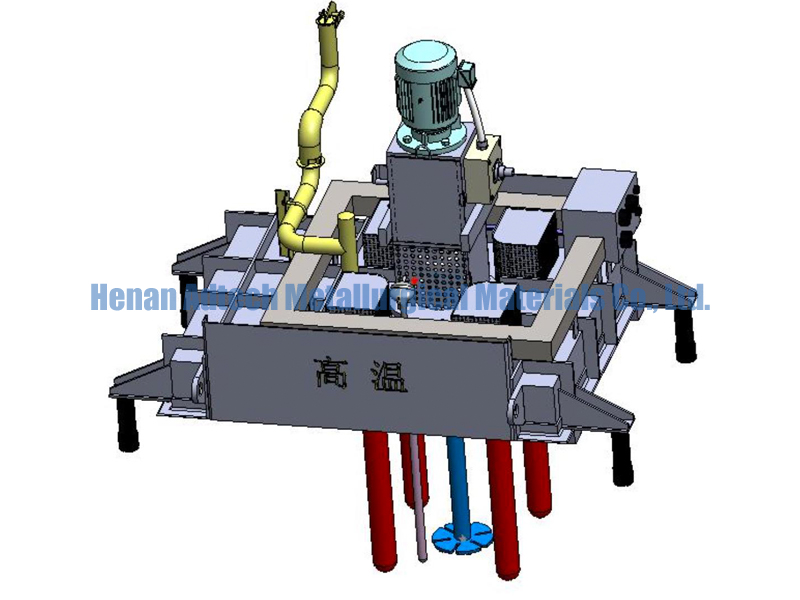

AdTech Rotary Degassing Machines uses graphite components which are critical to successful metal treatment. The unique rotational movement of the rotor head shears bubbles to prevent gas from rising. The cleverly designed rotor pushes metal outward and pulls from the bottom to improve flow, thus increasing reaction surface area. It operates at a lower rpm and eliminates “dead zones” in the melt.

AdTech is an enterprise specialized in new material development and high precision online degassing unit production since 2012, got positive feedback from domestic and overseas market.

Online degassing unit adopts advanced high silicon melting technology to get a long service time, degassing rotor, heater protection thimble and thermocouple protection thimble adopt ceramic manufacturing technology which can meet producing high-precision aluminum requirements.

Online degassing unit shall be installed between furnace and casting equipment. It is used for hydrogen (H) and slags removal from molten aluminum. The online degassing unit has dual functions: processing and heating. It serves high precision molten aluminum purification industry.

Assembling of Rotary Degassing Machines:

Mechanical Drive

Degassing Box &Cover

Rotor &Heater

Electric Control

No Comments