30 8月 PASARGAD Ceramic foam filter ensure high purity of aluminum alloys casting

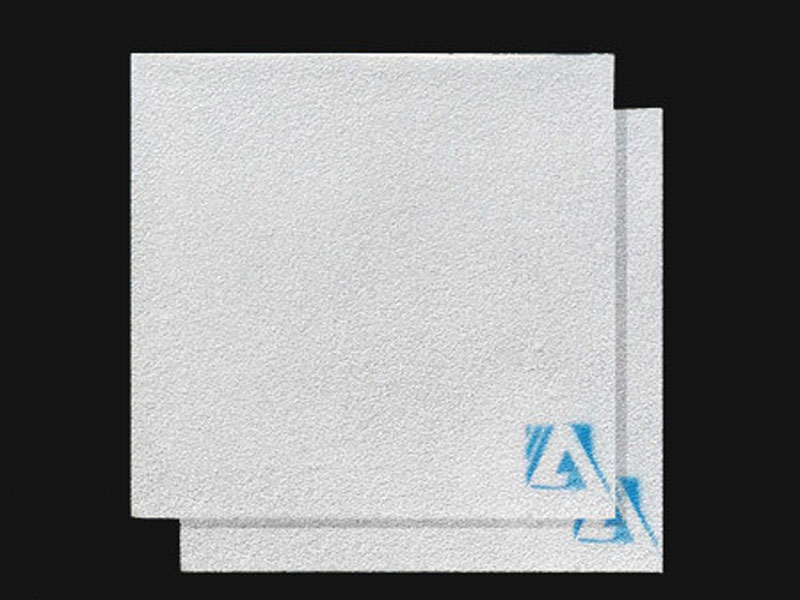

Ceramic foam filters are designed to ensure high purity of blank casting of aluminum alloys in metallurgical plants and for filtering aluminum castings in foundries.

Filters have a three-dimensional structure of interconnected pores forming a labyrinth of the ceramic filter body. Filters are distinguished by a homogeneous ceramic structure with a minimum of blocked places on both working surfaces. In this way, optimal conditions are created for the effective operation of all filtering mechanisms.

The chemical composition of Al2O3-based filter ceramics provides an efficient trapping of undesirable impurities, especially inclusions of a similar composition (oxide traps). Due to its high stability, even with prolonged exposure to high temperatures, filters can be successfully used in filtration boxes or in heating furnaces for filtering large volumes of liquid metal.

CASTING FILTERS

Foundry filters can be installed in the filter chamber of the gate system of the mold or used for direct casting technology of castings through an insulating or exothermic insert. They can be combined with insulating sprues made of ceramic fibers.

Filters can be easily placed in the risers in the case of low-pressure casting technology. A special type of filter for this technology is the so-called “filter plugs”.

METALLURGICAL FILTERS

Metallurgical filters are produced in the form of a truncated pyramid; main dimensions are in inches. The beveled side walls serve as a supporting surface for landing in a ceramic filter box.

In addition to the standard filter sizes, it is possible to supply filter segments of various sizes and shapes without beveled sides, which in most cases are loaded in a vertical position in the filter boxes or in the lining of furnaces. It is recommended to equip all types of filters with sealing or expansion tape, which ensures that the filter is firmly fixed in the correct position.

Cracks or holes on both work surfaces are not allowed. Side faces can be hardened with ceramic mass.

TRANSPORTATION AND STORAGE

Cardboard boxes and containers with ceramic foam filters are transported in covered vehicles. Ceramic foam filters are stored exclusively in closed, dry storage facilities. Stacking cardboard boxes is allowed in no more than seven layers.

If during transportation and storage the filters were in conditions of high humidity, they must be dried at 110 ° C before use until the moisture is completely removed.

TECHNICAL DETAILS

Chemical composition:

Al2O3, SiO2

Temperature:

Max. 1350 ° C

Structure:

ceramic

Colour:

white (various degrees of whiteness of filters are allowed)

Porosity:

10, 20, 30, 40, 50, 60 ppi; ppi combination e.g. 20/40, 30/50

Filter surface:

flat or profiled (corrugated)

Sealing pasting:

sealing tape – cf.g.2mm; 6.4mm; expansion tape – ex.g.3,1mm

The main forms:

circle, square. rectangle; truncated pyramid, truncated cone

Tolerances

+ 0.5 / – 1.5 mm to 100 mm

sizes:

+ 0.5 / – 2.5 mm for 100 -150 mm the rest – according to the specification of metallurgical filters

FILTER OPERATIONS

Persons working with ceramic foam filters must consider their fragility. When removing from the boxes, the filter must be easily tapped or purged with a stream of compressed air to remove possible small ceramic particles. When handling casting filters, it is preferable to work without gloves.

In no case should the shape of the filter be changed – either by sharp or grinding. The shape and dimensions of the filter must fully correspond to the installation location in the gate system or in the filtration box. When designing and choosing the shape, size and porosity of the filter, it is necessary to observe the applicable principles and standards that apply to the required amount of metal and casting speed (see table of casting filters).

Even before the use of metallurgical (large) filters, it is necessary to preheat them using suitable equipment so that the maximum filtration rate is achieved over all filter surfaces. You can use electric or gas heating. Heating should take place gradually and evenly over the entire surface. If the filter is equipped with an expansion sealing tape, special attention must be paid to the edges of the filter during heating. The filter, heated to a temperature of 350 – 400 ° C, is ready and suitable for use.

Adtech provides these products for Aluminium Casting Industry – www.adtechamm.com – sales@adtechamm.com

Online Degassing Unit Ceramic Foam Filter Plate-Type Filtering Unit

Sorry, the comment form is closed at this time.