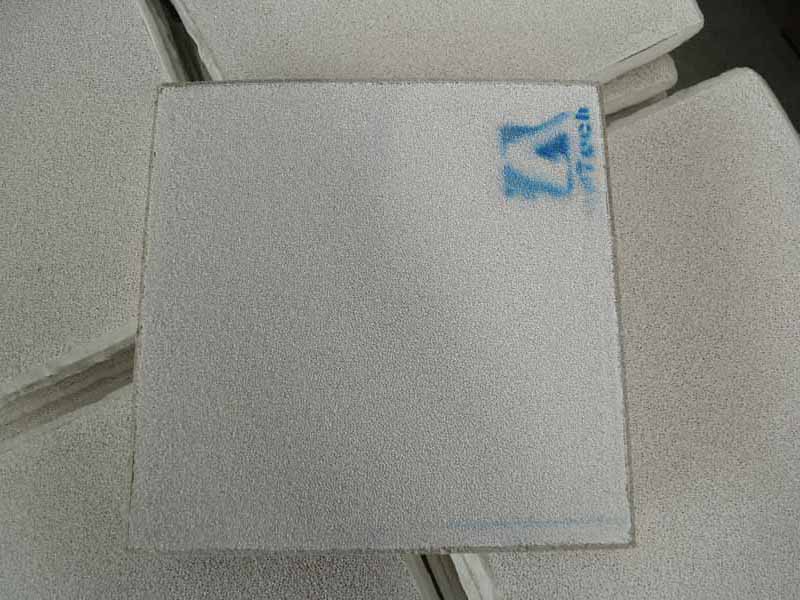

20 10月 Ceramic Foam Filter Casting

Ceramic Foam Filter Casting is mainly used for the filtration and purification of aluminum and alloy liquid in foundries with excellent resistance to corrosion and corrosion of aluminum liquid. It can effectively remove inclusions, reduce trapped gas, provide laminar flow, and the filtered metal is significantly cleaner. Cleaner...