02 12月 Feeder Caster Tip

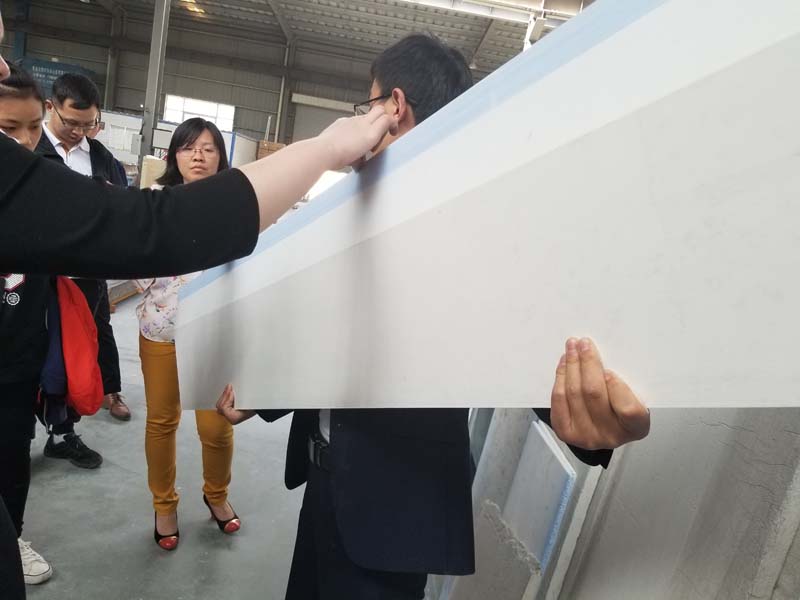

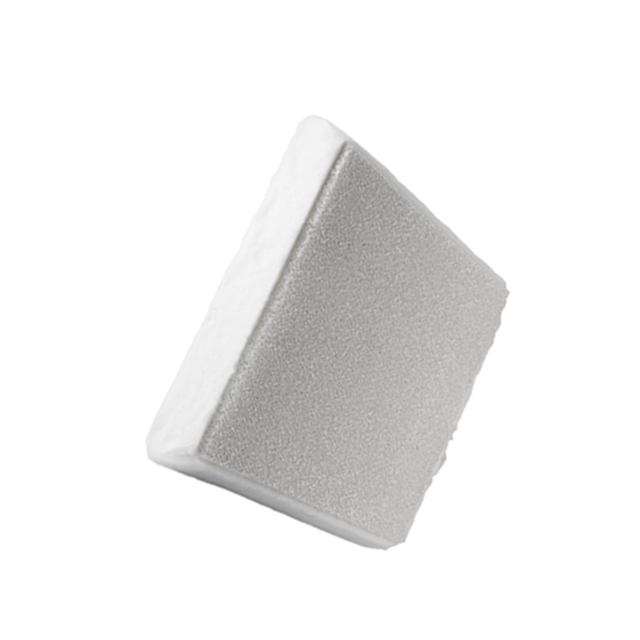

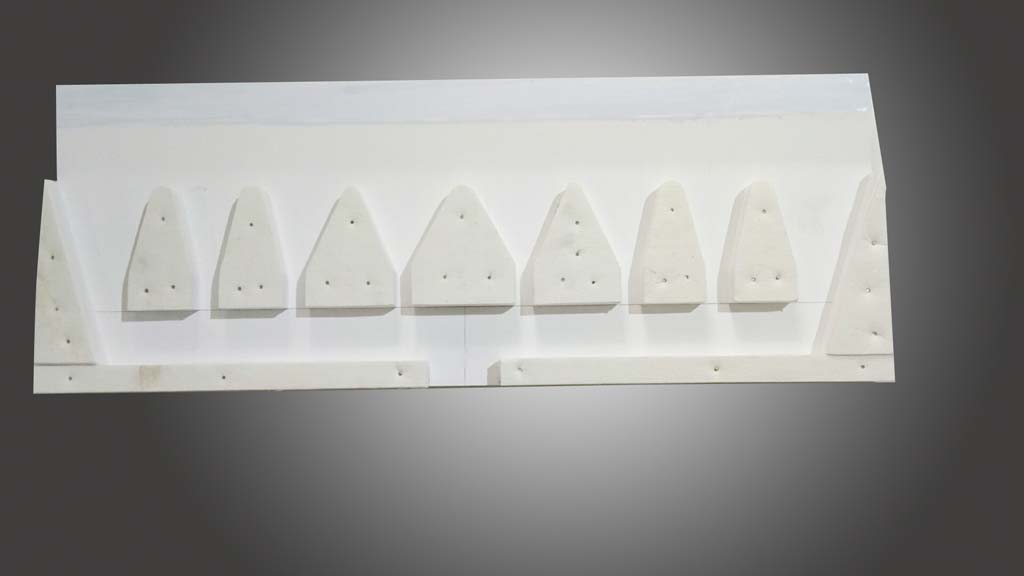

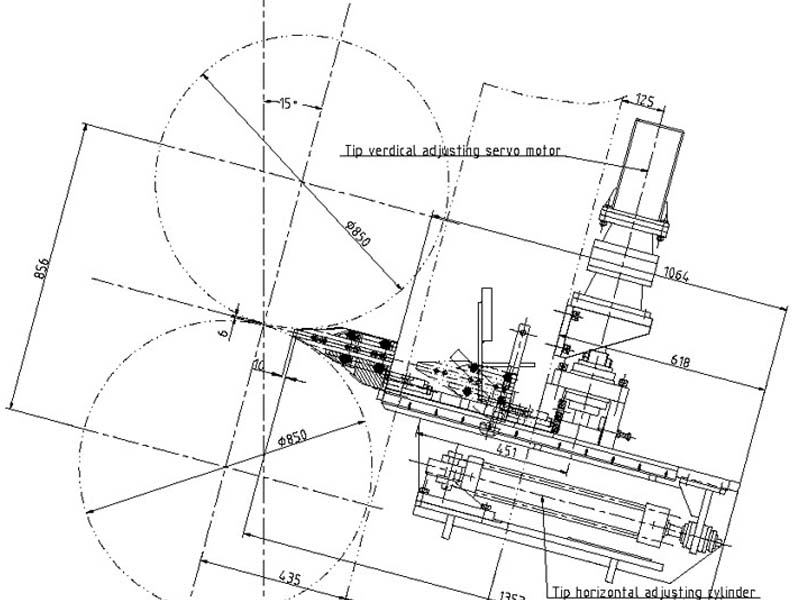

Feeder Caster Tip During the aluminum strip casting process, molten aluminum is fed from the elongated casting tip (or "discharge nozzle") into the nip between two counter-rotating water-cooled rolls. The molten aluminum is cooled when it comes into contact with the rolls and cools as it...