26 11月 Aluminium Degassing Problem Analysis

Aluminium Degassing Problem Analysis

Aluminium Degassing Problem Analysis -Degassing tank cover slagging

1.Mainly because the current structure of aluminum liquid is too low from the cover. The scum splashed up during refining.

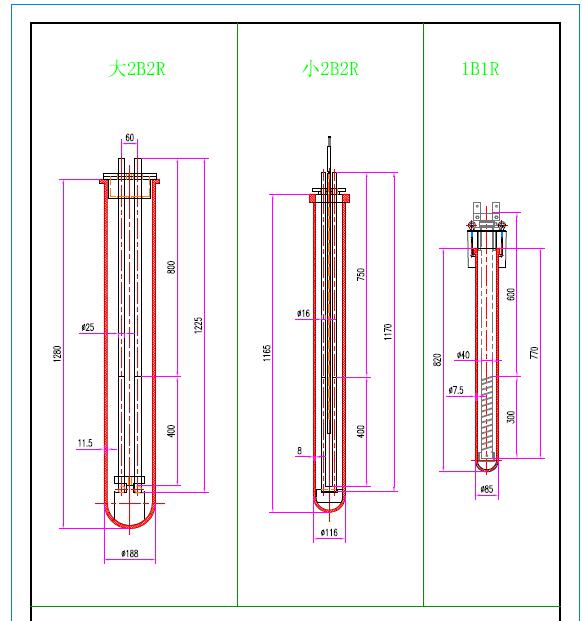

2.To solve the problem of slagging, change the structure of the box and find the matching rotor and heater casing.

3.There is no cover on the upper part of the slag hole, which affects the seal. Recommended to add a cover.

4.The rotor sleeve has a large gap, which affects the seal. It is recommended to use packing seal.

Aluminium Degassing Problem Analysis -Hydrogen flashover during use of the equipment

1.When the rotation speed is low and the gas flow rate is large, the liquid level fluctuates greatly and large bubbles appear.

2.After adjustment, the liquid level is stable and the hydrogen flash is evenly distributed.

Aluminium Degassing Problem Analysis -Rotor use

The rotor uses a 10-month photo with no wear and no slagging.

No Comments