11 1月 Filter Casting Aluminium Brazil

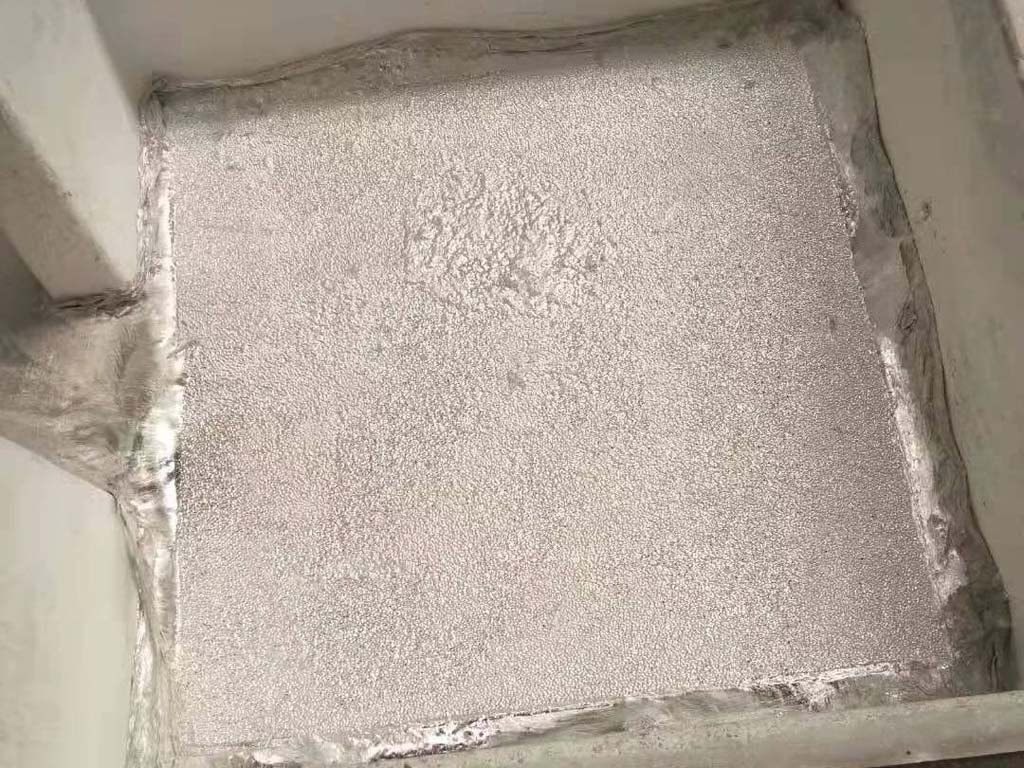

Filter Casting Aluminium Brazil to remove inclusions generated between the refining system and the mold table.

The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the metal solidification process. Therefore, the quality and productivity of downstream operations such as forging, extrusion and rolling are guaranteed.

Aluminium Brazil placed the ceramic foam filter in the CFF Unit, and the aluminum and aluminum alloys were fed into the hot top casting platform through the launder. The casting machine produces various aluminum rods.

Aluminium Brazil purchased Filter Casting through sales@adtechamm.com and introduced that it has the following advantages

1. The filter has excellent resistance to erosion and corrosion of molten aluminum, and can effectively remove inclusions.

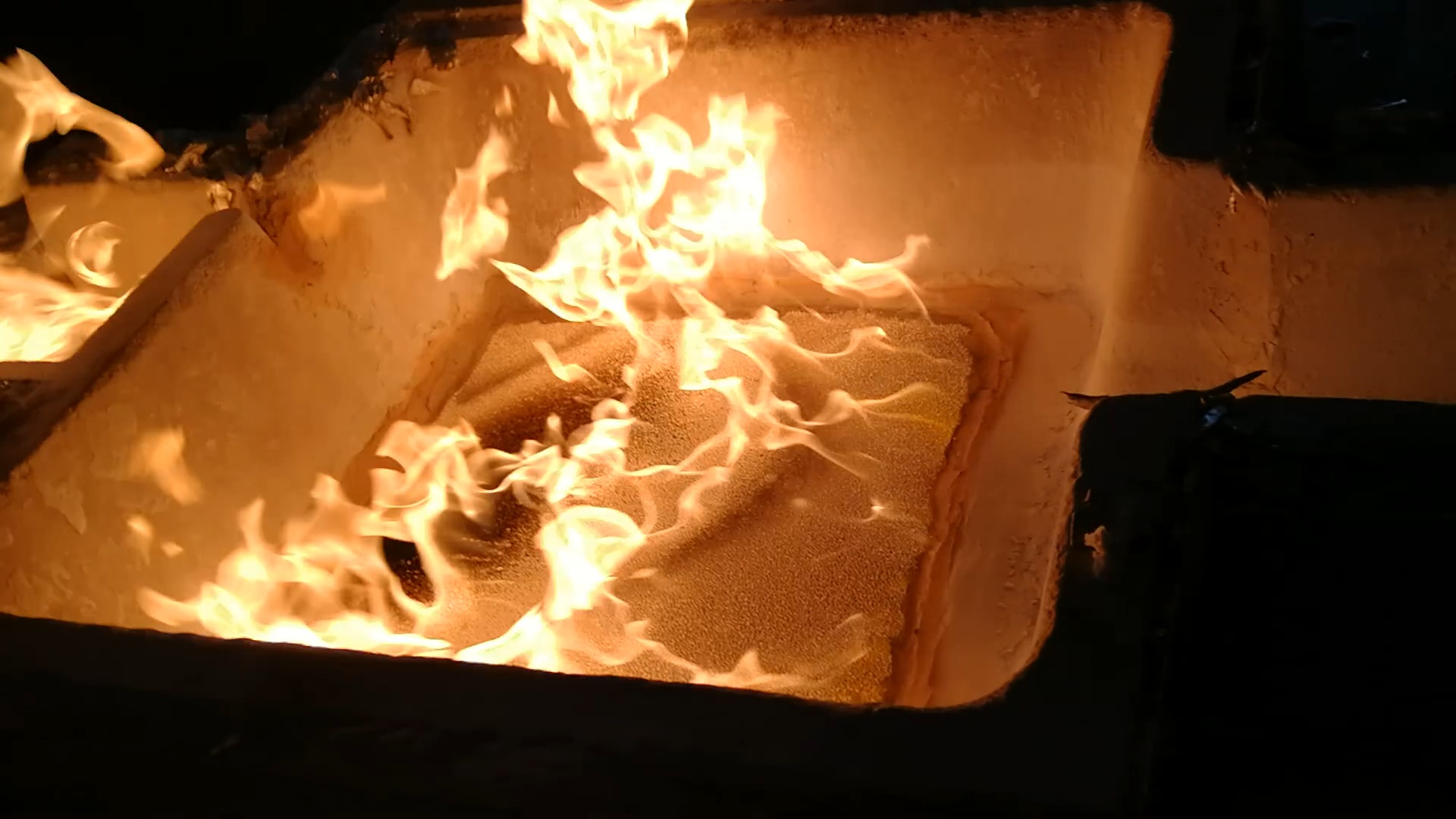

2. Reduce residual gas and provide laminar flow, and then the filtered metal is significantly cleaner.

3.Cleaner metal can produce higher quality castings.

4. Fewer waste products and fewer inclusion defects, all of which help increase profits.

As the largest aluminum melting and casting plant in South America, Aluminium Brazil has extensive experience.

During the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, is easily oxidized, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag (and coarse intermetallic particles, etc.). wait.

On the other hand, part of the waste in the composition charge contains some non-aluminum impurities during the recycling process.

Since the waste comes from process waste, waste from various processes in the factory, and waste outside the factory, the route is different, the composition is complicated, and the quality is poor.

These impurities are easy to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

Sorry, the comment form is closed at this time.