24 5月 Dubal America Inc – Metal Transfer Runner

Dubal America Inc – Metal Transfer Runner

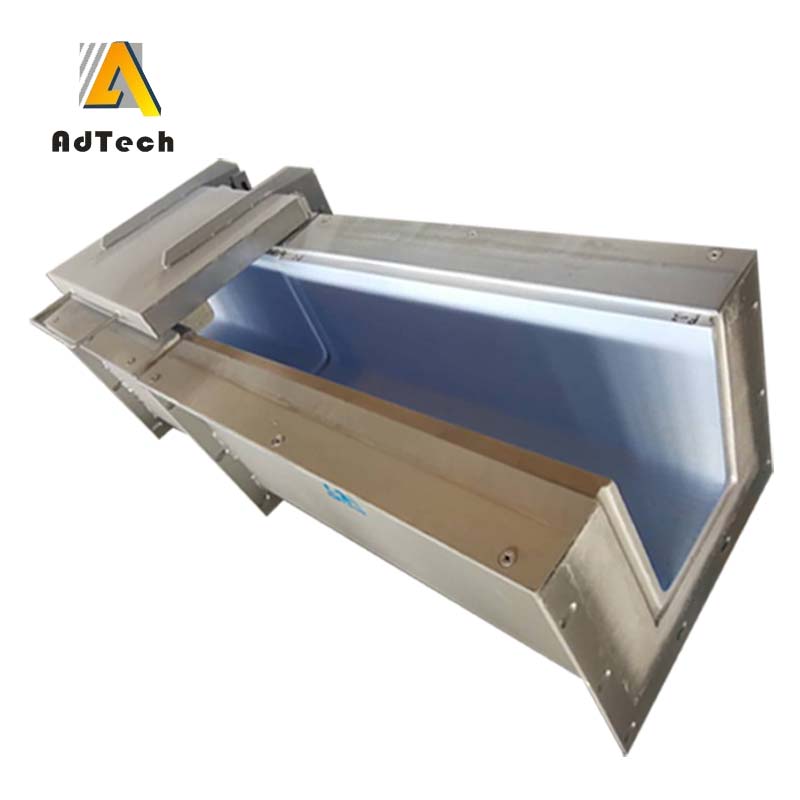

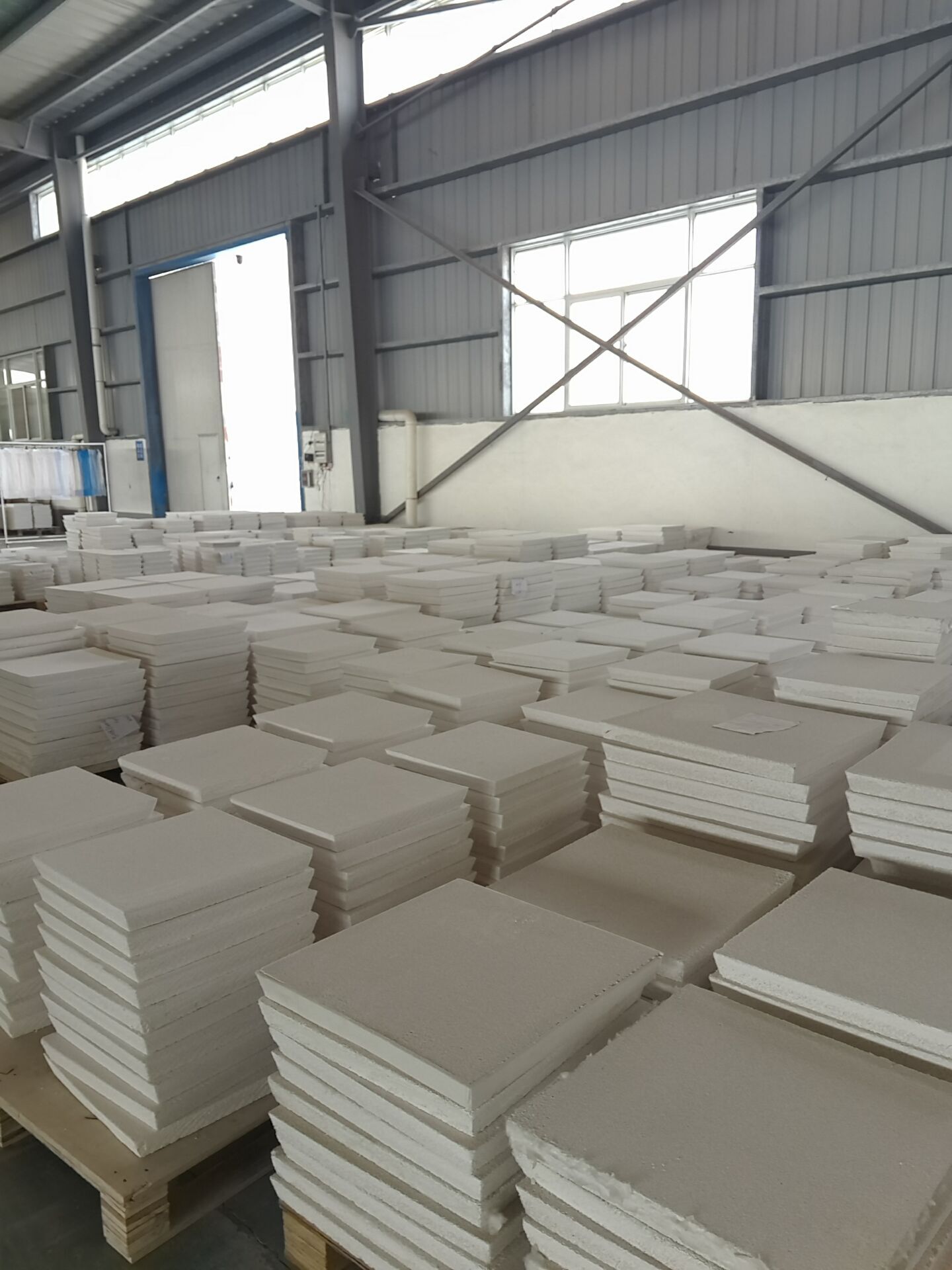

Metal Transfer Runner System Also known as Insulating Launder, it is a silicic acid fiber product and is mainly used for aluminum liquid distribution and transmission with higher requirements for heat preservation, such as live casting and rolling.

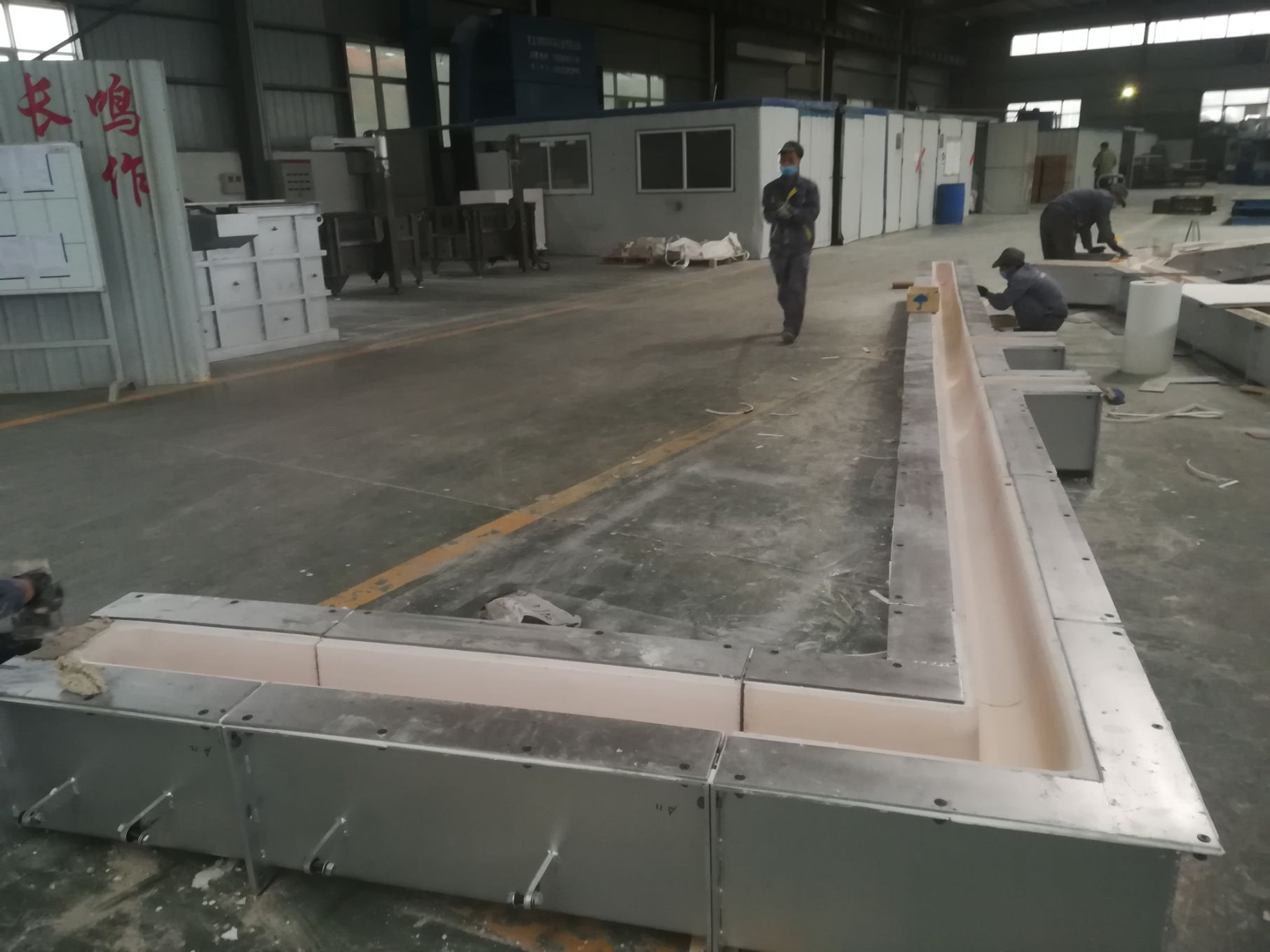

The runners and the runners on the same horizontal casting disc. Color is white? Raw material composition High aluminum fiber size according to customer requirements according to the map processing:

Length ±2mm Width ±1mm

Other properties Density 0.50-0.60g/cm3

Thermal conductivity ≤0.12W/m.k at 720°C

Maximum use temperature 1250°C Continuous use temperature 800°C

Compressive strength ≥0.35Mpa Flexural strength ≥0.25Mpa

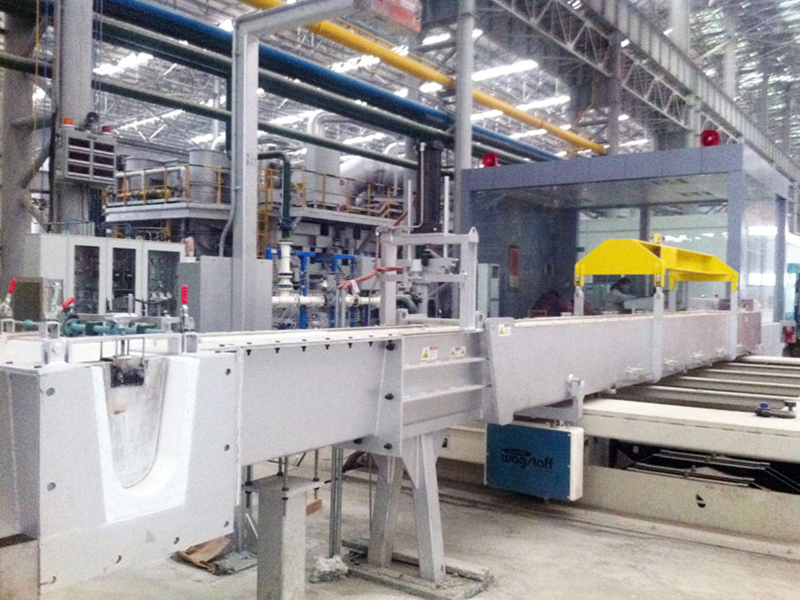

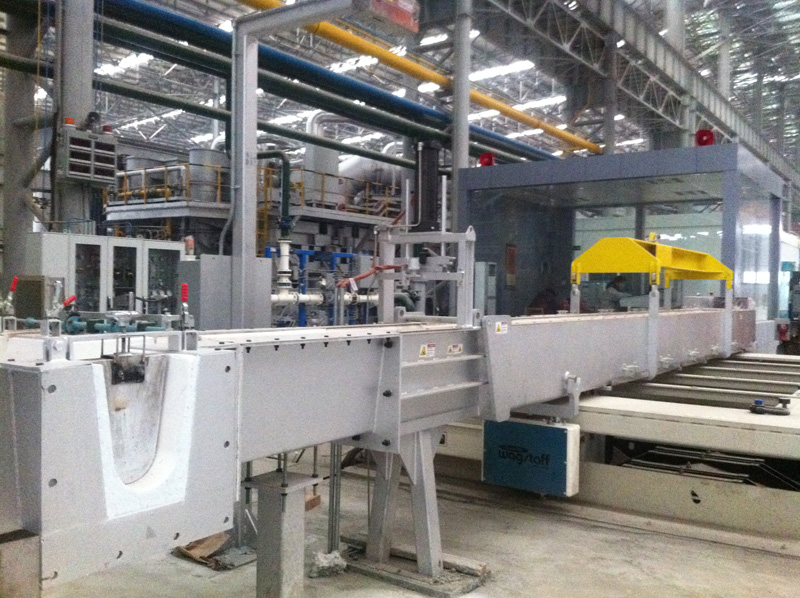

Metal Transfer Runner System applications:

Aluminum furnace calcium silicate board bonding, insulation brick masonry, brick seams. Aluminium water heat preservation flow channel refractory fiber felt bonding. Aluminum flow trough shaped parts repair. High-temperature equipment, casting material gaps, holes to fill, firebrick masonry, other fire insulation board paste.

Aluminum heat sink features:

Pure alumina clay, pure material after sintering, can effectively control the cleanliness of aluminum water. Appearance form: viscous mud-like colloid; good adhesion: high viscosity, good paste effect, solid masonry; high refractoriness: high refractoriness above 1700, high operating temperature, suitable for many environments; convenient construction : Bottled finished product, ready-to-open; long service life: corrosion resistance, anti-peeling.

Model NSJ-1 Operating temperature range °C ≤1650 Refractoriness°C ≥1700 Wet gravimetric weight g/cm3 2.1~2.2 Construction dosage paste kg/m2 6~8 Masonry building kg/m3 200~250 dry chemical composition % Al2O3 ≥85SiO2 ≤15 Cold-resistance bond strength MPa 110°C ≥31000°C ≥51400°C ≥8 Packing barrel, 40kg/barrel

Metal Transfer Runner System used:

Metal Transfer Runner System containing calcium silicate board (referred to as calcium silicate board), also known as non-asbestos calcium silicate board, micro-porous calcium silicate board, is composed of silicon and calcium having a content of ≥92% Material-based, a new type of sheet made of pulping, forming, steaming, drying, sanding and post-processing, which is a non-asbestos high-performance insulation Materials, with low bulk density, high strength, low thermal conductivity, high temperature resistance, corrosion resistance, ability to cut, energy saw, etc., are widely used in electric power, metallurgy, petrochemical, construction, boilers, cement and other industries, boilers, industrial furnace insulation.

Ivans Al-water heat sink includes a preform and a glaze layer, the preform has a flow groove in a longitudinal direction, an upper surface of the flow groove is in an open shape, and the glaze

The layers cover the three inner sides of the flow cell, the thickness of the bottom of the preform is H1, the depth of the flow cell is H2, and the ratio of H1:H2 is in the range of 1:3-8.

between. The utility model provides an Metal Transfer Runner System with a simple structure, a fast flow speed and a good heat preservation effect.

No Comments