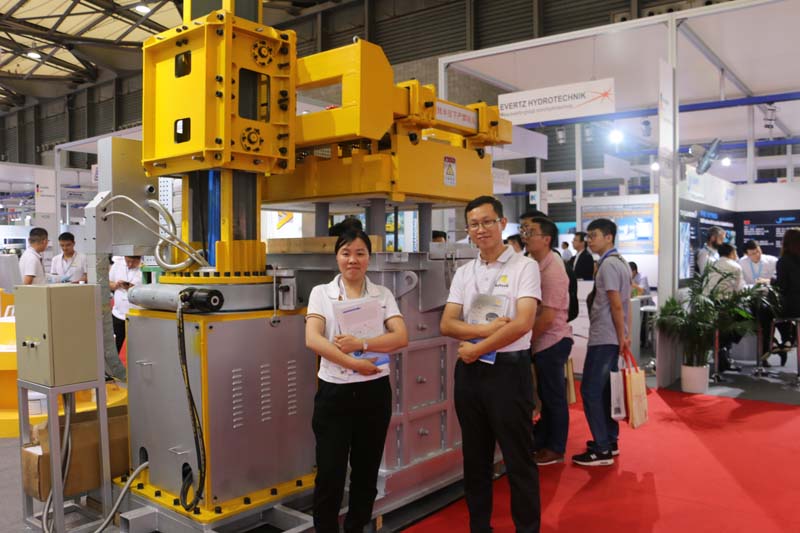

16 10月 Double Rotor Degassing Euipment

Double Rotor Degassing Euipment

The double rotor degassing equipment has high degassing efficiency: the double rotor degassing equipment adopts a compact furnace design, and a deaeration tank is arranged on the flow channel, and the baffle is divided into a plurality of degassing units to effectively increase the inert gas and the aluminum. The contact probability of the liquid; the small bubbles can be fully diffused in the aluminum liquid; thereby improving the degassing efficiency of the device.

Convenient operation: The dual-rotor degassing device is simple and easy to use, and adopts a simple rotor drive mechanism, which greatly reduces the complexity of the system and reduces the maintenance cost of the equipment. At the same time, the user’s requirements for casting quality are considered in the design of the equipment, and the refined gas is refined. Both flow and rotor speed are adjustable.

Convenient maintenance: The design of the dual-rotor degassing equipment fully considers the convenience of equipment maintenance. Considering the convenience of equipment maintenance and rotor replacement, the rotating nozzle part and the heater part can be lifted separately, which is convenient for maintenance. operating. When the workshop site is relatively narrow, the amount of infrastructure work during equipment renovation can be reduced, and the user’s different requirements for the quality of the ingot can be met.

The double rotor degassing device can realize continuous degassing of the aluminum melt, and the aluminum melt processing amount is large. The device consists of a tank, a lid, a heating system, a vent system, and a refining system. It removes hydrogen and other impurities from the aluminum melt. The double degassing rotor, the heater protection sleeve and the thermocouple material are all silicon nitride materials independently developed by Evans. Together with Evans’ unique internal mixing spoiler design, it can ensure a good stable degassing effect. According to the amount of processing, the equipment can be divided into single-chamber single rotor (1B1R), double-chamber double rotor (2B2R) and three-chamber three-rotor (3B3R).

The double rotor degassing equipment is the main means of improving the comprehensive performance of the aluminum alloy by the aluminum alloy purification treatment process. In the purification treatment process, the purification gas and the solvent are mixed, and the method of purifying the aluminum melt by the rotary injection of the graphite rotor is the most advanced treatment method in the world.

The working principle of the double-rotor degassing device is that the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large amount of dispersed bubbles and disperses them in the molten metal. In the melt, the gas is separated by the partial pressure difference of the gas and the surface adsorption principle, absorbs the hydrogen in the melt, adsorbs the oxidized slag, and is taken out of the surface of the melt as the bubble rises, so that the melt is purified. Due to the fine dispersion of the bubbles, it is uniformly mixed with the rotating melt, and then rotates in a spiral shape and slowly floats. The contact time with the melt is long, and the gas flow generated by the continuous straight rise is not formed, thereby removing harmful hydrogen in the aluminum melt, which is remarkable. Improve the purification effect.

No Comments