22 10月 Degassing Device Manufacturer

Degassing Device Manufacturer

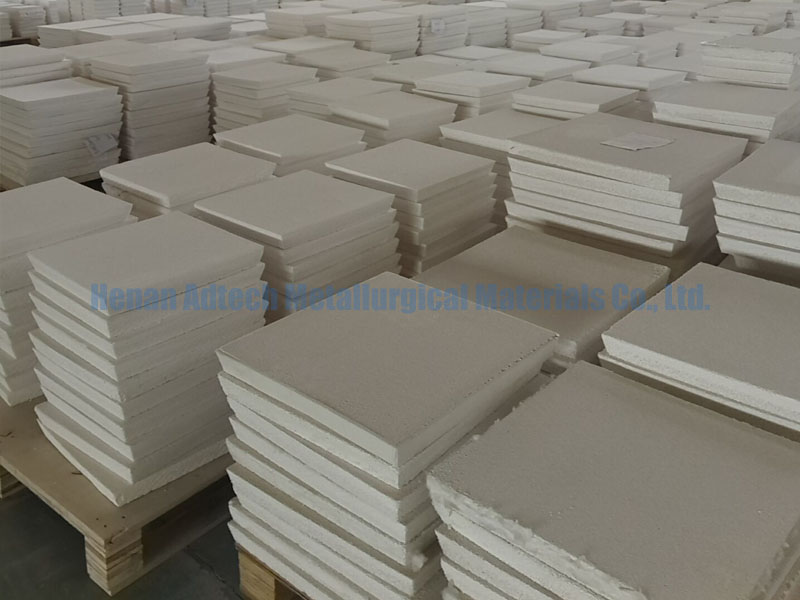

The AdTech online degassing unit has a long life furnace with a new high silicon melt material manufacturing technology. The degassing rotor, heater protection sleeve and thermocouple protection sleeve are made of silicon nitride (Si3N4) ceramics. Production of aluminum products with high added value and high technical performance requirements.

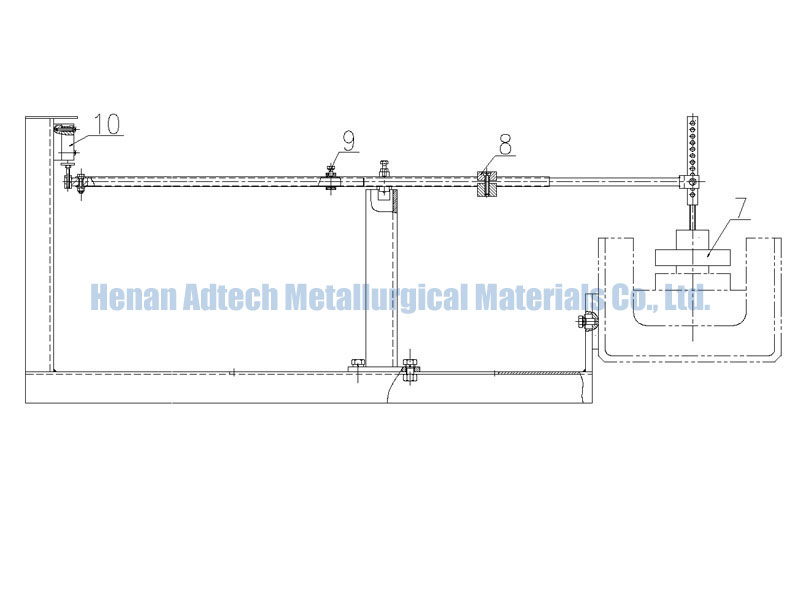

The online degassing unit from AdTech is installed between the furnace and the casting machine to remove hydrogen and other residues from the molten aluminum and its alloys that affect its quality and mechanical properties. It has dual functions: handling and heating. Mainly used for melt purification of high-precision aluminum products, such as: computer hard disk, color and black and white copier drum, micron aluminum foil wool, printing PS board base, can material, aircraft landing gear (intercrystalline high-strength aluminum ), jet turbine engine fan blades and other products.

The degassing device contains a large amount of hydrogen, metal and non-metal slag in the melted aluminum and aluminum alloy melt. If the above harmful impurities are not removed in time before casting, pores, slag inclusions and looseness will be formed inside and on the surface of the casting. Such casting defects seriously affect the physical, chemical, mechanical and deep processing properties of the cast parts, resulting in a large amount of waste. The degassing device can remove these impurities before casting;

Visit the Degassing Device Manufacturer Adtech website:www.adtechamm.com

There are two methods for removing these impurities from the degassing device. One is to use refining treatment in the furnace, and the other is to perform on-line processing on the casting production line. It is proved that the degassing and slag removal by on-line treatment is to improve the metallurgical quality of the aluminum liquid. Best method;

Degassing device degassing principle: the aluminum liquid is stirred by a controlled rotating graphite shaft and a rotor, and the metered inert gas is pressed into the aluminum liquid through the rotor and dispersed into fine bubbles, which are uniformly dispersed in the liquid metal. The gas partial pressure of the bubble is zero. Because the partial pressure of hydrogen in the aluminum liquid is high, the hydrogen in the aluminum liquid continuously diffuses into the bubble, and part of the non-metallic inclusions in the aluminum liquid are adsorbed on the surface of the bubble, useless hydrogen and Some of the non-metallic inclusions adhere to the inert gas bubbles floating up to the liquid surface. When there is a special degassing filter box, the impurities are isolated before the pouring, and then the desulfurization and deoxidation inclusions are achieved by the slag. The degassing principle is also recognized, the efficiency is high, the production process is not affected, the purity of the aluminum liquid can be improved in a short time, the scrap rate can be reduced, the production efficiency can be improved, the mechanical properties of the casting can be improved, and the competition of the product can be enhanced. Force, which is not achieved by traditional degassing methods.

Our “Evans Jiaozuo Metallurgical Materials Co., Ltd.” has made great demands on the quality control of each degassing device. Since the listing, it has received favorable comments from users and users. I believe that our brand will get more in the future. More applications.

No Comments