28 8月 Ceramic foam filters for the melt

Ceramic foam filters for filtering the melt

Today, a promising area of industrial use of reticulated polyurethane foams is the production of ceramic foam filters.

Ceramic foam filters are used to eliminate impurities in metal castings.

PPU-based filters remove impurities through their open cell structure.

The path of the molten metal passes through the pores during the casting process.

In the direction of the ceramic foam filter, PUF is used as a substrate for further catalytic processes.

The foam is coated with a ceramic suspension and dried.

The blanks of various shapes are then placed in a furnace where the matrix of the reticulated polyurethane foam is burned out leaving the ceramic frame of the finished filter.

Ceramic filters have a pore size range of 10 to 30 PPI / linear inch.

The mesh structure of the ceramic foam filter provides deep filtration, carefully removing large amounts of impurities and no impurities.

The filter is able to withstand significant metal static pressure while maintaining effective filtration.

Ceramic foam filters are commonly used in primary and secondary aluminum smelting, as well as in aluminum smelting furnace filters.

Ceramic foam filter has the following advantages

Filtration of metallic and non-metallic impurities from molten metal streams

Reduce oxides during turbulent formation

Increase metal flow

Eliminate inclusions and various metal defects

PPU filter has good mechanical properties and can improve casting quality

Reduce waste and extra work in production

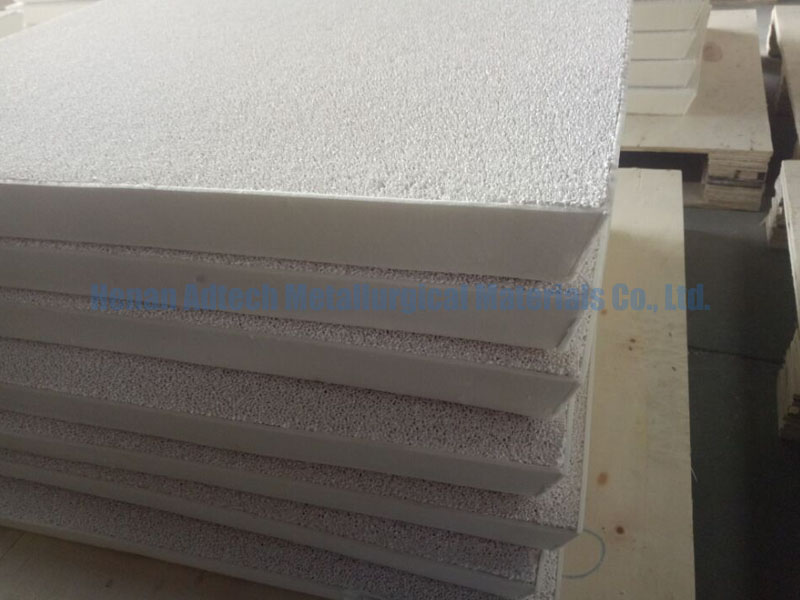

Ceramic foam filters come in a variety of sizes and shapes.

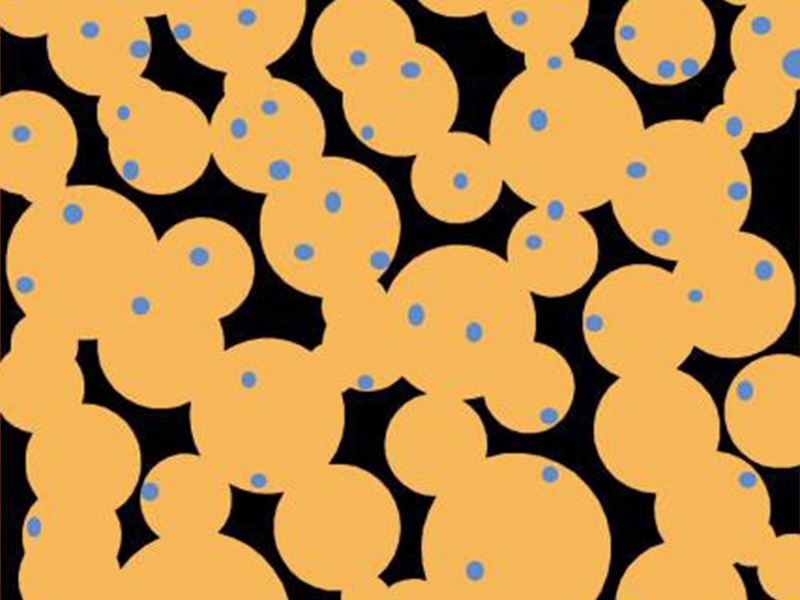

All ceramic foam filters are characterized by a network of substrates, spherical pores of uniform size and volume being connected to each other throughout their volume and forming a window through their walls. The winding path of the structure passes through and simultaneously captures slag and other contaminants.

Thus, this unique PPU-based filter structure exhibits superior metal filtration efficiency compared to other filter structures in the foundry market.

Ceramic foam filters have high heat resistance and are easily impregnated with molten metal.

PPU-based filters offer outstanding durability without the need for redundant metal screens.

Online Degassing Unit Ceramic Foam Filter Plate-Type Filtering Unit

Alumina Ceramic Ring Tap Out Cone Refining Flux

Sorry, the comment form is closed at this time.