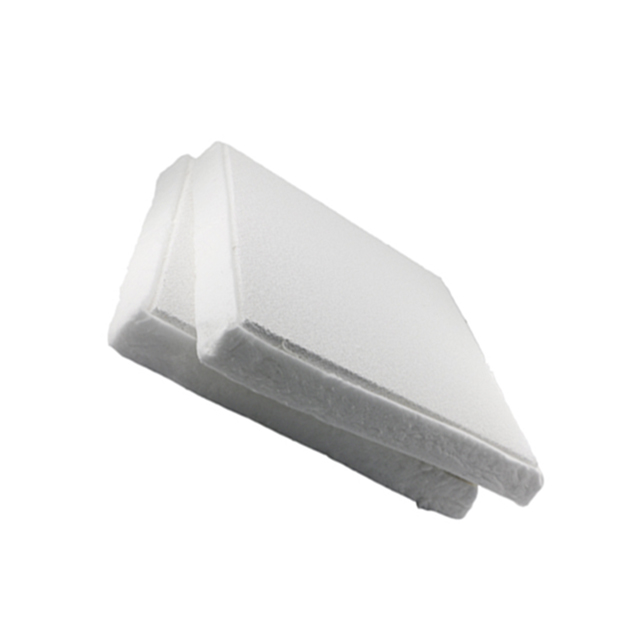

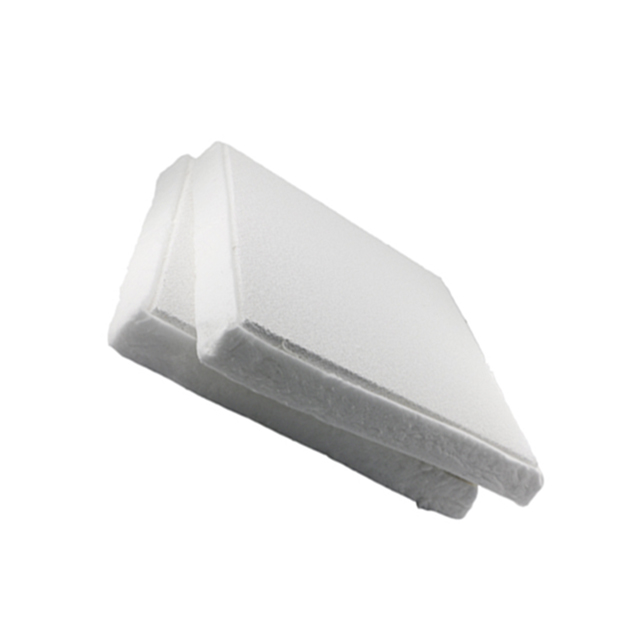

20 5月 Ceramic Foam Filter Sweden

Ceramic Foam Filter Sweden is purchased from Adtech China, please contact email: sales@adtechamm.com

Aluminum alloy castings are more and more widely used in the development of the automotive industry, and the requirements for castings are becoming higher and higher. Therefore, the added value of aluminum alloy castings in the automotive industry is relatively high.

Chemical composition, mechanical properties and dimensional accuracy all have high requirements. Automobile aluminum alloy castings are not allowed to have casting defects such as shrinkage holes, air holes and slag holes.

These will seriously affect the safety performance of the car.

Ceramic Foam Filter Sweden is one of the measures to ensure high-quality aluminum alloy products in the automotive industry, and is also the main means to increase the added value of aluminum alloys.

The refinement of the aluminum liquid has an important influence on the formation of pores, shrinkage pores and inclusions,

Directly affect the physical and mechanical properties of aluminum alloy castings.

If Ceramic Foam Filter Sweden is not used to process aluminum slag, even if the subsequent treatment is more advanced, once defects are generated, they will always exist in the product, making it difficult to obtain high-quality castings.

Therefore, we must pay attention to the gas and inclusions in the aluminum liquid, and take measures to remove the gas and inclusions in the aluminum liquid.

Inclusions refer to any solid material present in the aluminum liquid.

Common non-metallic impurities in aluminum liquid are oxides, nitrides, carbides, borides, etc.

In addition to charge, it is mainly the product of chemical reactions in the melting process.

In addition, some undesirable primary intermetallic compounds will appear in high alloy melts, such as aluminum zirconium, aluminum titanium, etc., and iron-containing aluminum alloys will also form iron-rich aluminum-iron-iron phases, aluminum aluminosilicate silicate, and aluminum-silicon-iron phase It is a needle-like compound that severely damages the aluminum matrix and affects mechanical properties.

Sorry, the comment form is closed at this time.