27 3月 Ceramic Foam Filter Singapore

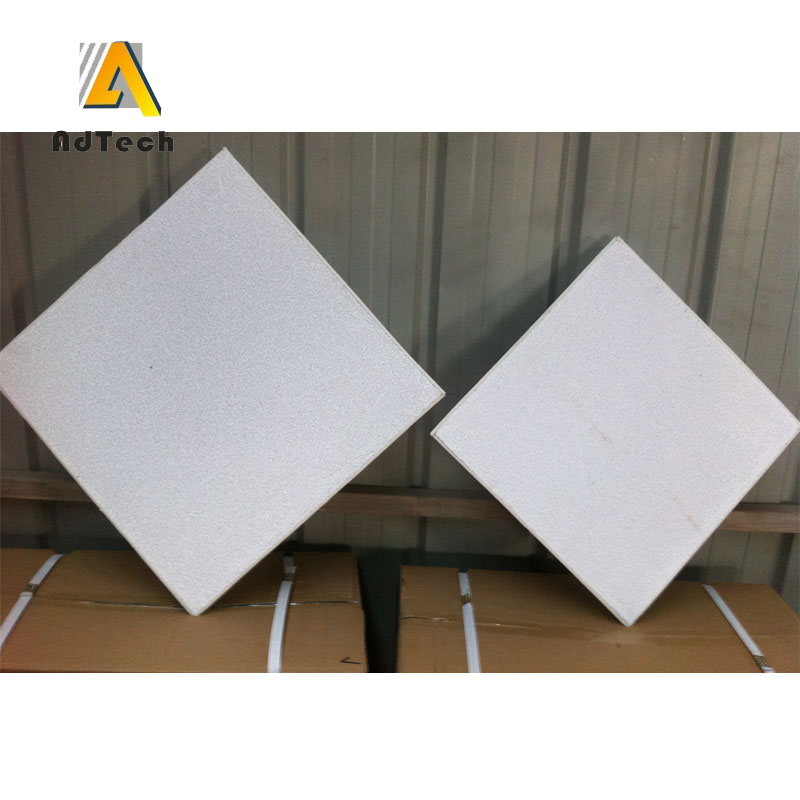

Ceramic Foam Filter Singapore

Ceramic Foam Filter Singapore use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Ceramic Foam Filter Singapore Advantages

Ceramic Foam Filter Singapore offer the best way to eliminate non-metallic inclusions, foreign materials that are a major source of quality problems in casting. and help you meet ever increasing demands for quality.

Get rid of the impurity, refractory scrap, solid refractory alloy, sinter, in the molten metal liquid when casting the products, get rid of turbulent flow, reduce the air cavity of castings, raise the quality of cast. So our ceramic foam filters (foamed ceramics) are widely used in the aluminum foundry industry, for preventing defects caused by oxides, dross, gas, slag and other impurities.

Eliminates turbulence in the metal stream, Smoothes out metal flow, avoiding sprays, splatter and backset. Improve fluidity, castability, machinability, yield and cost-effective.

Low-pressure loss.

Provides consistent flow rate and capacity.

Various sizes, shapes and pore sizes are available.

How Does Efficient Filtration Improve the Whole Process

AdTech Ceramic Foam Filters offer benefits that improve molten metal handling, casting, machining, and the finished product itself.

Ceramic Foam Filter Singapore Feature

1>. 3D reticulate structure

2>. High mechanical strength, no-dregs off when flapping

3>. High porosity

4>. Large surface areas, strong absorptivity of impurities

5>. Excellent thermal shock resistance

6>. Rapid improvement in filed

Ceramic Foam Filter Singapore manufacture- ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

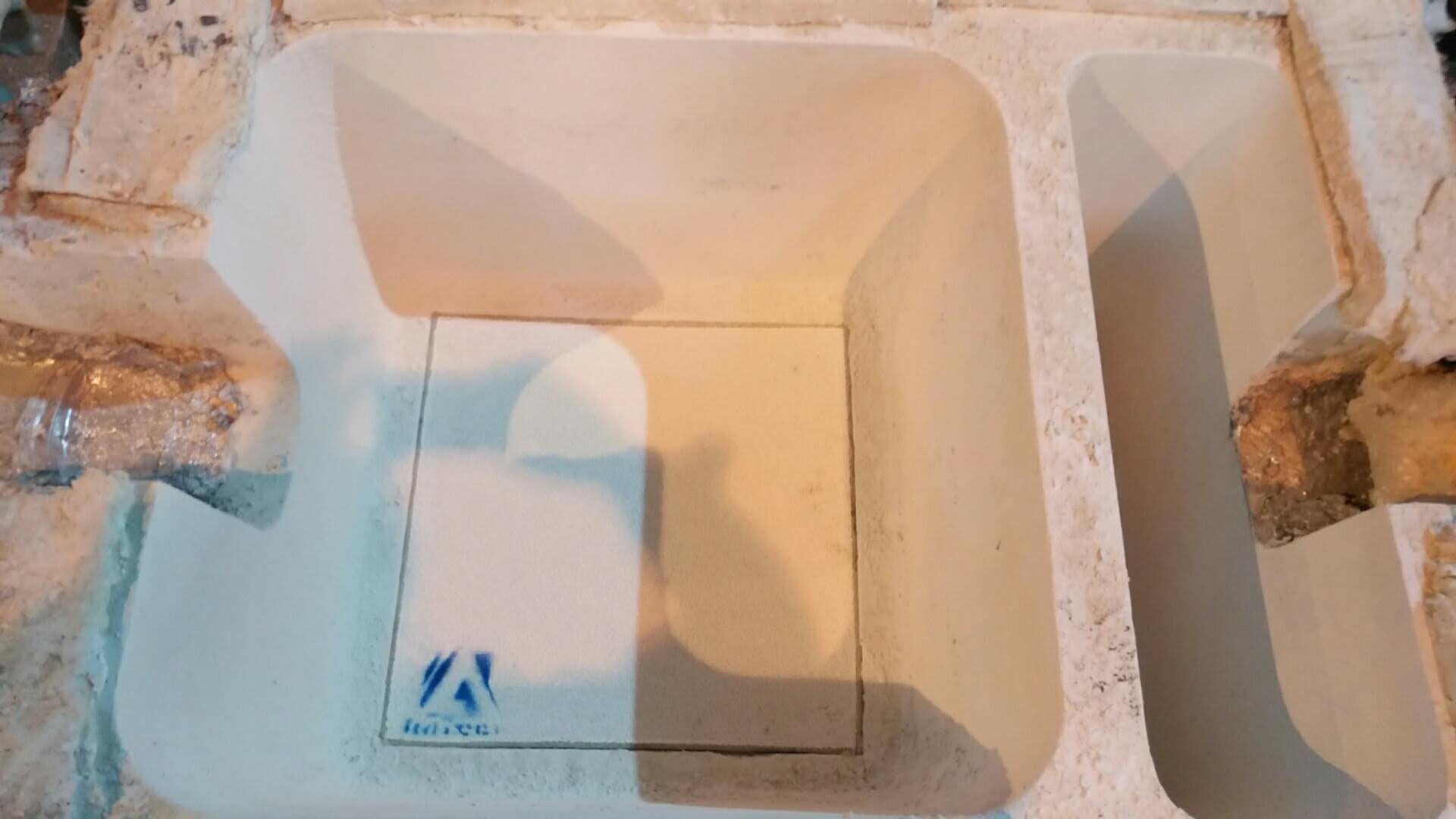

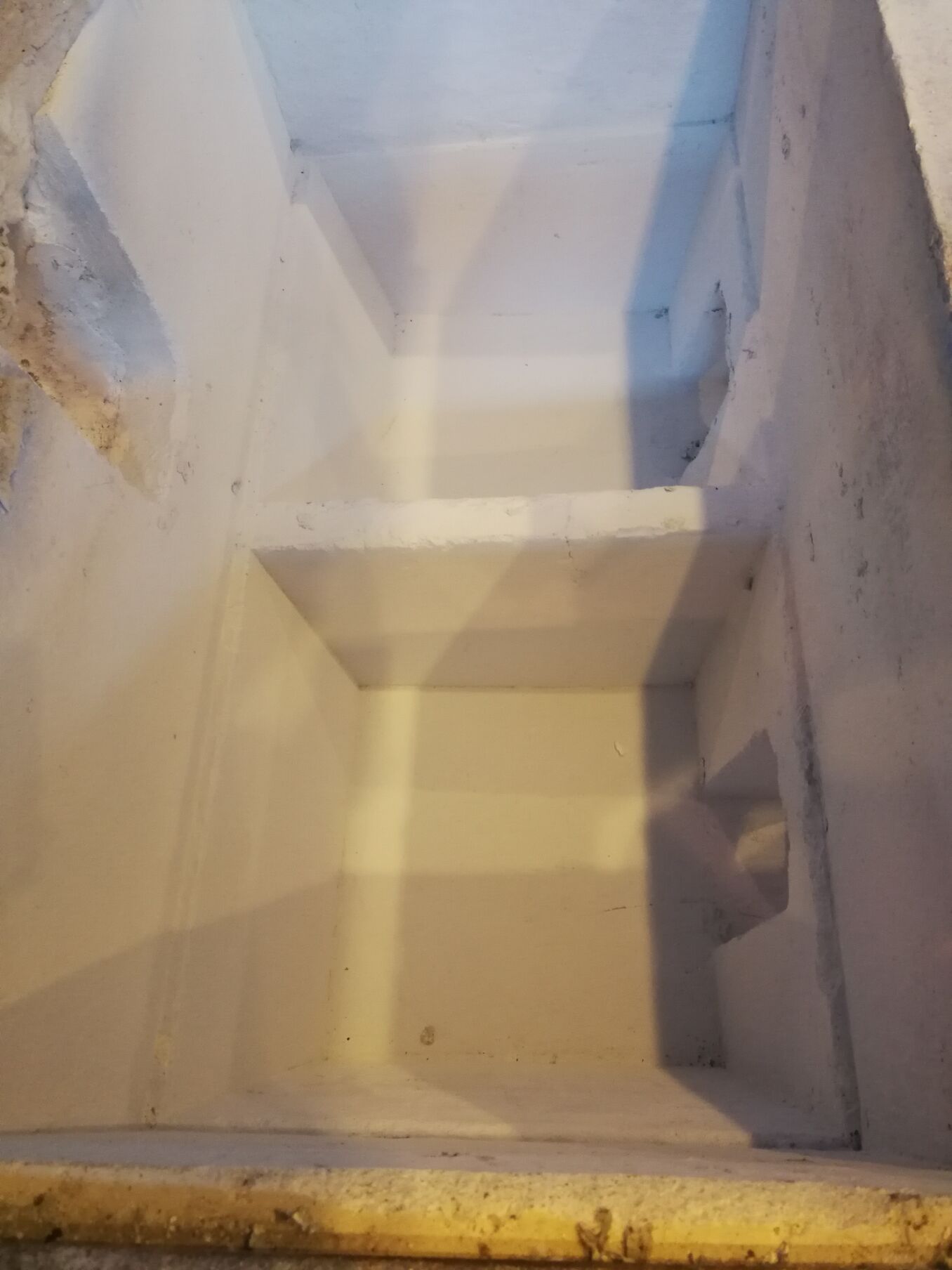

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

No Comments