03 4月 Ceramic Foam Filter CFF

Ceramic Foam Filter CFF

Non-stick aluminum Ceramic Foam Filter CFF basic structure and classification:

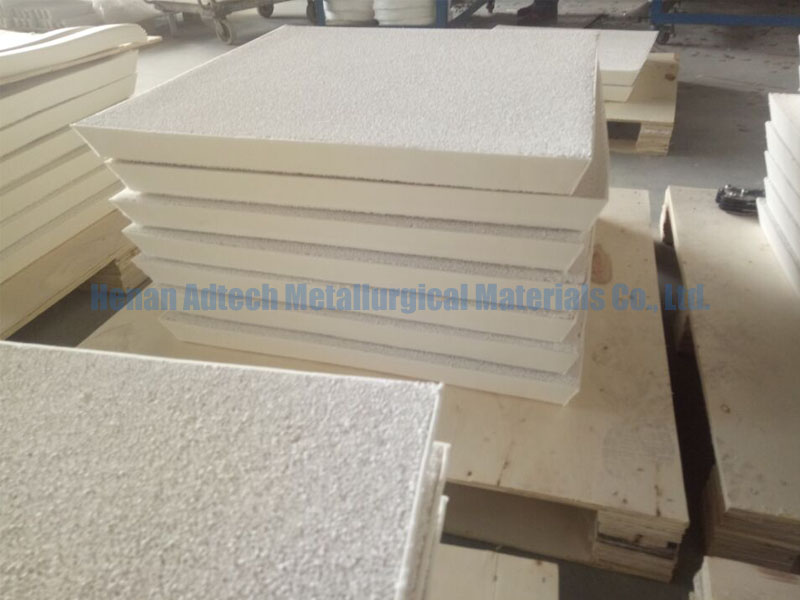

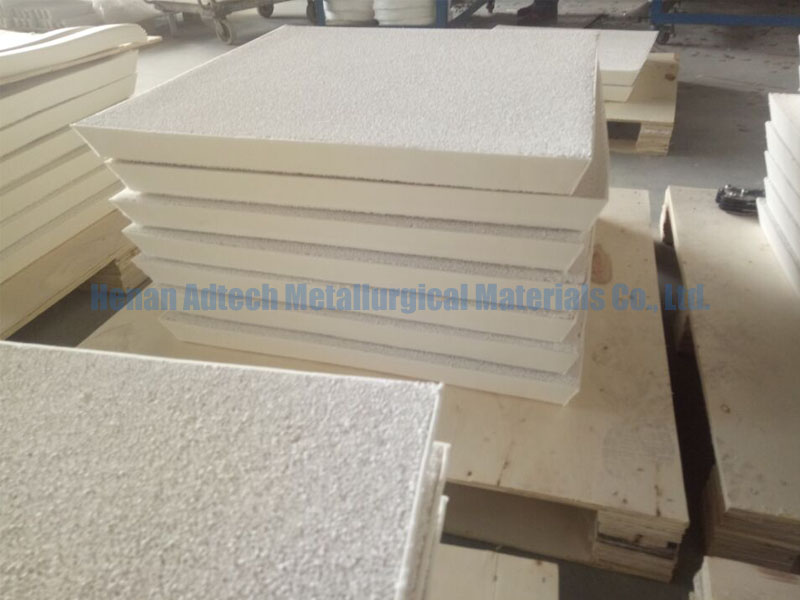

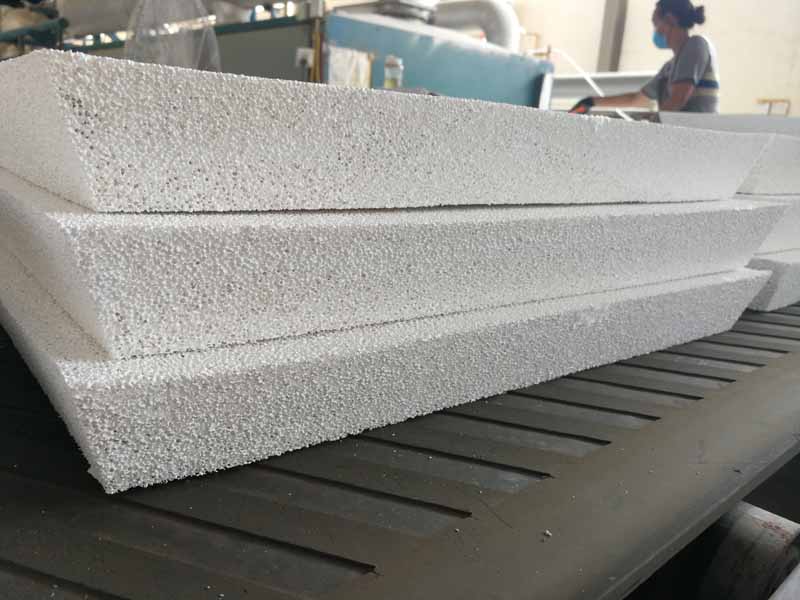

The Ceramic Foam Filter CFF plate consists of a base plate, a surface film, a water outlet, a positioning seat, and the like.

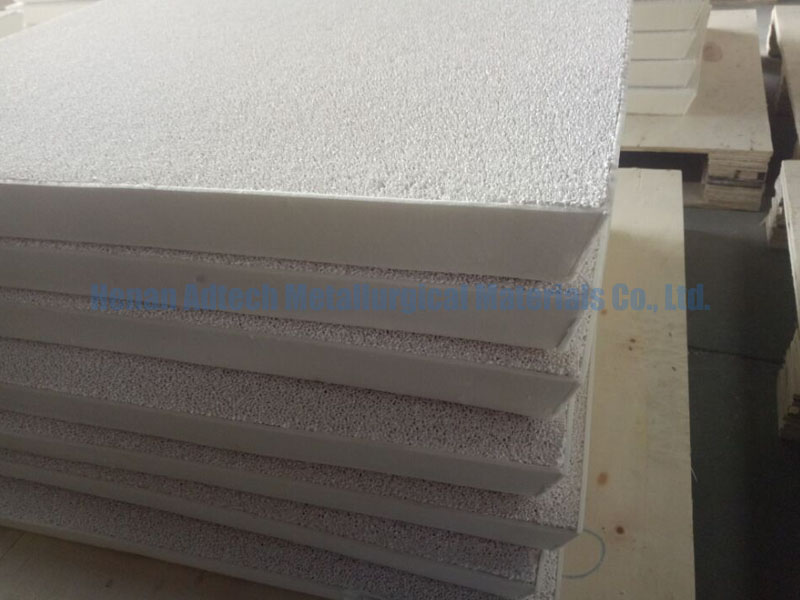

The Ceramic Foam Filter CFF plate is the core component of the Ceramic Foam Filter CFF. It is a new type of porous functional ceramic material. It is filled with criss-crossing capillary pores (about 1 to 10 microns in diameter). They are the filtrate (water). Channel, this component is called the board base layer. The components of the Ceramic Foam Filter CFF plate include corundum, silicon carbide and other materials.

Ceramic Foam Filter CFF plate outlet, positioning base main components are stainless steel or polymer material;

Non-stick aluminum Ceramic Foam Filter CFF plate features

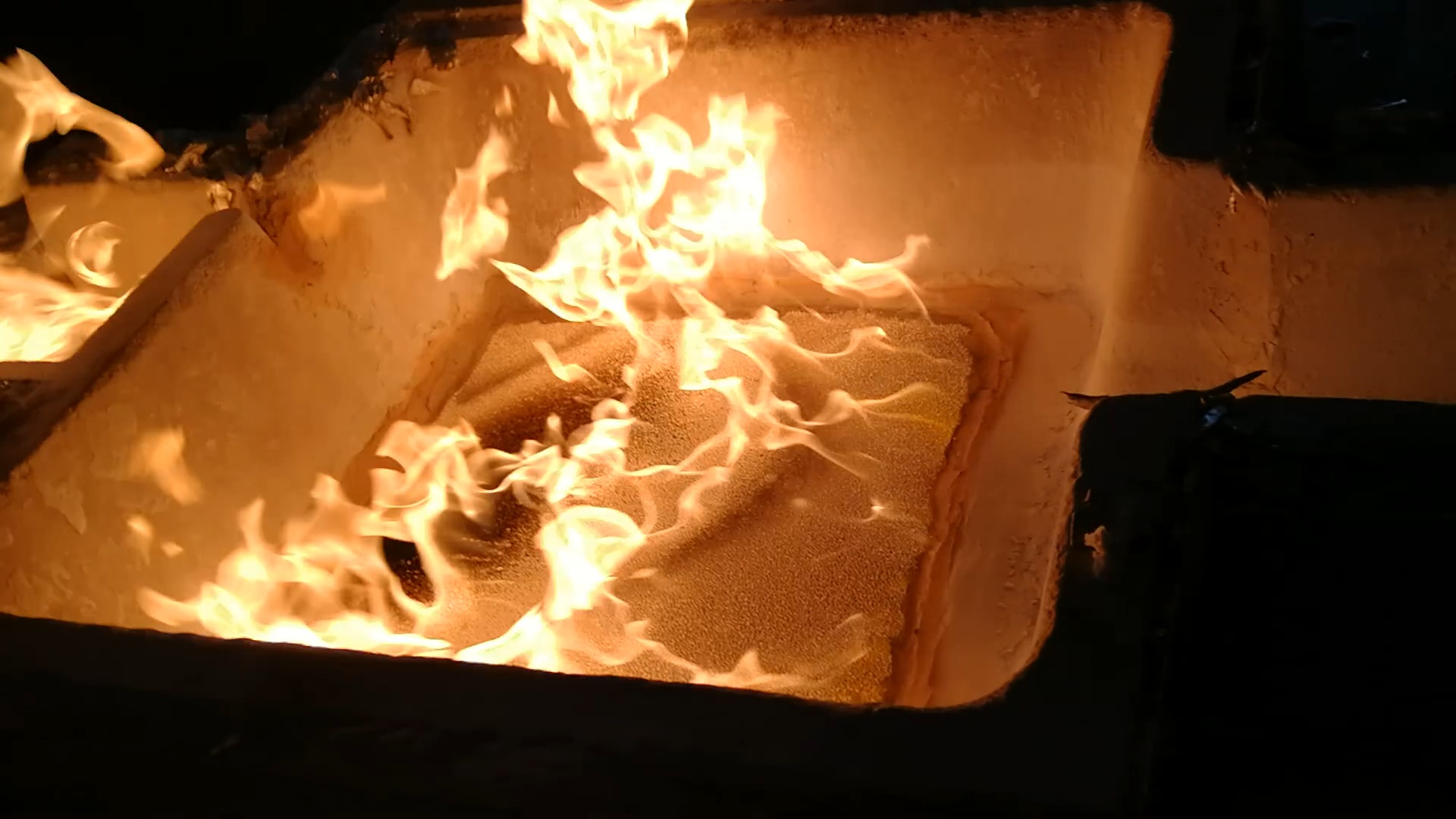

Non-stick aluminum Ceramic Foam Filter CFF plate is the core component of the Ceramic Foam Filter CFF, suitable for industrial solid-liquid separation, material dewatering.

Uniform pore size distribution, high filtration accuracy, up to 0.1 micron, good self-cleaning, no pollution. Easy to regenerate, can be brushed, sanded, rinsed and backwashed. Microporous Ceramic Foam Filter CFF is based on diatomaceous earth as the main raw material, after molding. High-temperature sintering advanced filter material. The material is uniformly covered with silver ions and has antibacterial and antiseptic effects. It can effectively remove bacteria, fine-grained impurities, and viruses from the water. It can be widely used in the application of water, mineral water purification, sterilization, and sterile water for medical and electronics industries. Water, high purity water plug preparation, etc.

The main features of the Ceramic Foam Filter CFF plate are as follows:

1. Filtration precision covers fine filtration, microfiltration, ultrafiltration, nanofiltration, reverse osmosis;

2. High mechanical strength, stable chemical properties, good abrasion resistance, low resistance, resistance to clogging, and easy recoil;

3, high efficiency, high yield, uniform and stable filter aperture.

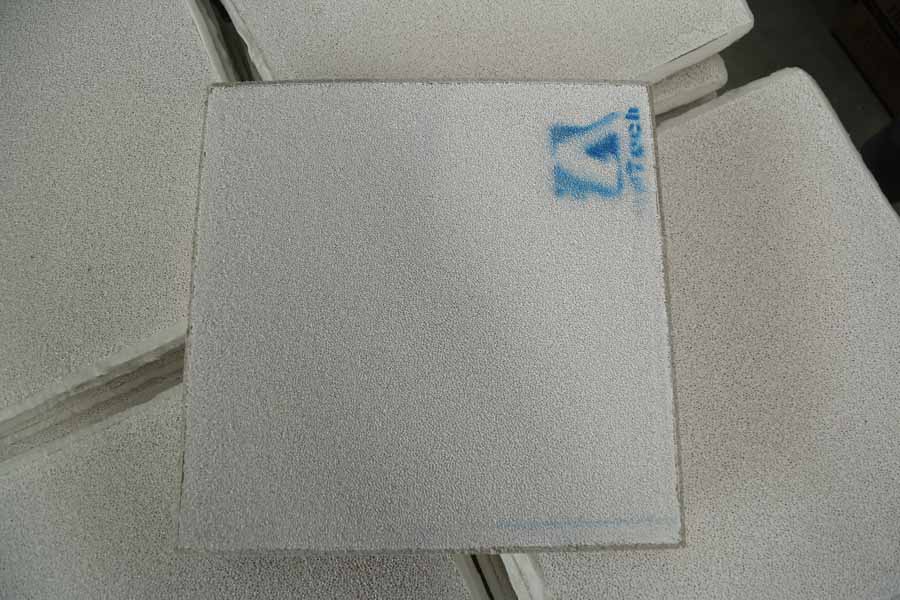

Non-stick aluminum Ceramic Foam Filter CFF plate representation

For example: 3 square meters of Ceramic Foam Filter CFF plate (3m2 / circle) indicates the method;

Said: KBT-3/2-II;

Definition: KBT is a code for Ceramic Foam Filter CFF plates; 3 means that the Ceramic Foam Filter CFF plate is a 3 m 2 Ceramic Foam Filter CFF plate (3 m 2 /turn); 2 refers to the surface aperture code of the Ceramic Foam Filter CFF plate, and its unit is μm; II means Ceramic Foam Filter CFF plate modification code.

Non-stick aluminum Ceramic Foam Filter CFF plate Advantages: high temperature resistance, high mechanical strength, corrosion resistance, no harmful substances, no secondary pollution, under the action of fluid pressure, easy to clean and regenerate, micro-holes do not deform, long service life, Can replace cotton, silk fabric, plastic, metal mesh, asbestos and other filter materials, widely used in petroleum, chemical, metallurgy, thermal power, cement, pharmaceuticals, paper and other industrial enterprises in the environmental protection “three wastes” in the solid-liquid separation, Gas-liquid separation, powder conveying, oil-water separation, separation in the wine industry, air filtration, circulating water filtration and other devices are particularly suitable for the filtration of boiler dust removal wastewater and flushing water. Precipitation + microporous Ceramic Foam Filter CFF new technology, novel design, simple construction, economical and practical;

No Comments