29 3月 Ceramic Foam Filter Aluminum Suriname

Ceramic Foam Filter Aluminum Suriname

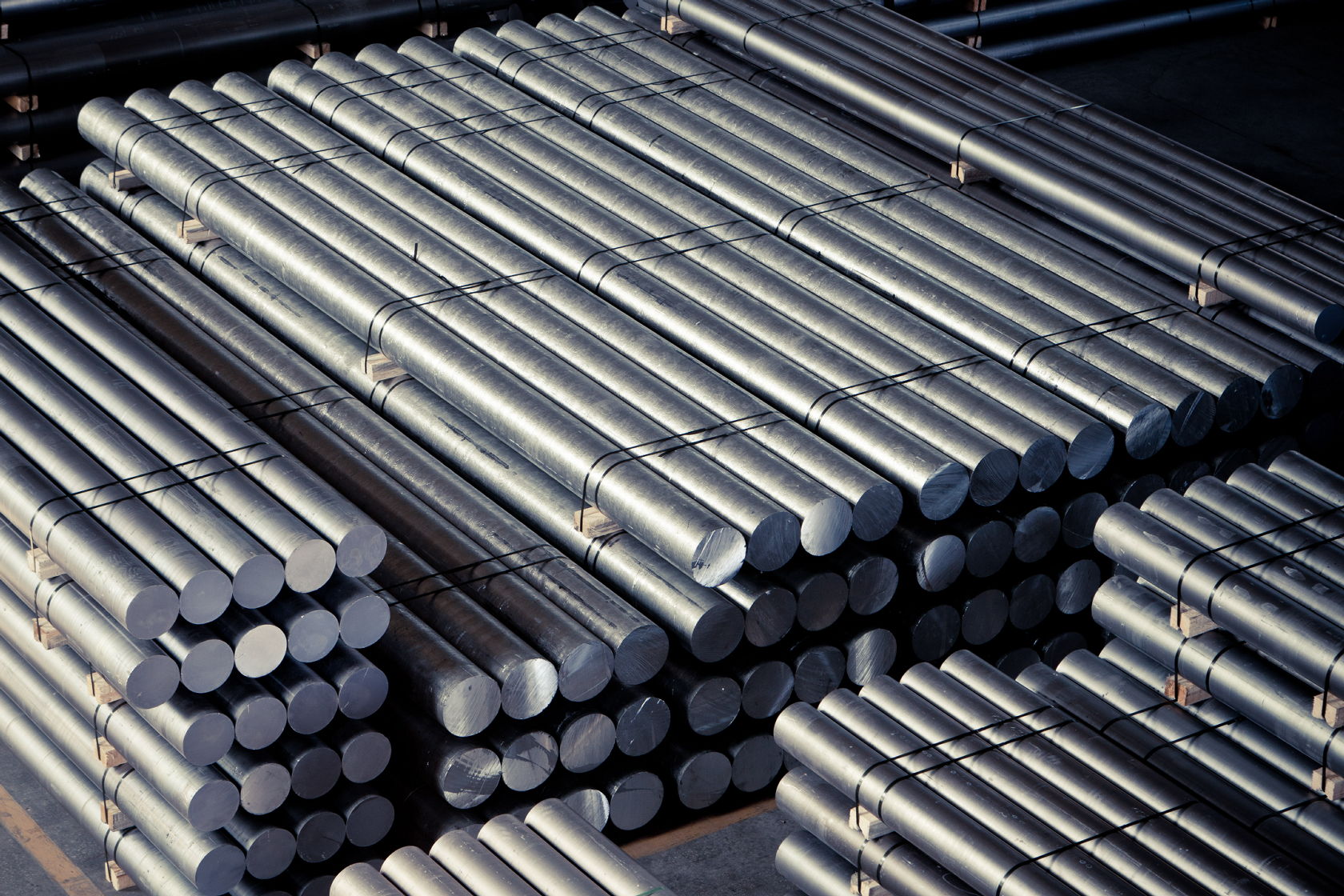

Suriname Aluminum Co., LLC engages in bauxite and alumina mining and refining. The company was founded in 19161 and is based in Suriname. Suriname Aluminum Co., LLC operates as a subsidiary of Alcoa Corporation.

Ninety-five percent of all beer and soft drink cans in the United States are made of aluminum.

American can makers produce about 100 billion aluminum beverage cans a year, equivalent to one can per American per day.

While almost all food cans are made of steel, aluminum’s unique properties make it ideal for holding carbonated beverages.

The typical aluminum can weighs less than half an ounce, yet its thin walls withstand more than 90 pounds of pressure per square inch exerted by the carbon dioxide in beer and soft drinks.

Aluminum’s shiny finish also makes it an attractive background for decorative printing, important for a product that must grab the attention of consumers in a competitive market.

Aluminum was first identified as an element in 1782, and the metal enjoyed great prestige in France, where in the 1850s it was more fashionable than even gold and silver for jewelry and eating utensils.

Napoleon III was fascinated with the possible military uses of the lightweight metal, and he financed early experiments in the extraction of aluminum. Although the metal is found abundantly in nature, an efficient extraction process remained elusive for many years.

Aluminum remained exceedingly high-priced and therefore of little commercial use throughout the 19th century.

Technological breakthroughs at the end of the 19th century finally allowed aluminum to be smelted cheaply, and the price of the metal fell drastically. This paved the way for the development of industrial uses of the metal.

Aluminum was not used for beverage cans until after World War II. During the war, the U.S. government shipped large quantities of beer in steel cans to its servicemen overseas.

After the war most beer was again sold in bottles, but the returning soldiers retained a nostalgic liking for cans.

Manufacturers continued to sell some beer in steel cans, even though bottles were cheaper to produce. The Adolph Coors Company manufactured the first aluminum beer can in 1958. Its two-piece can could only hold 7 ounces (198 g), instead of the usual 12 (340 g), and there were problems with the production process. Nevertheless, the aluminum can proved popular enough to incite Coors, along with other metal and aluminum companies, to develop better cans.

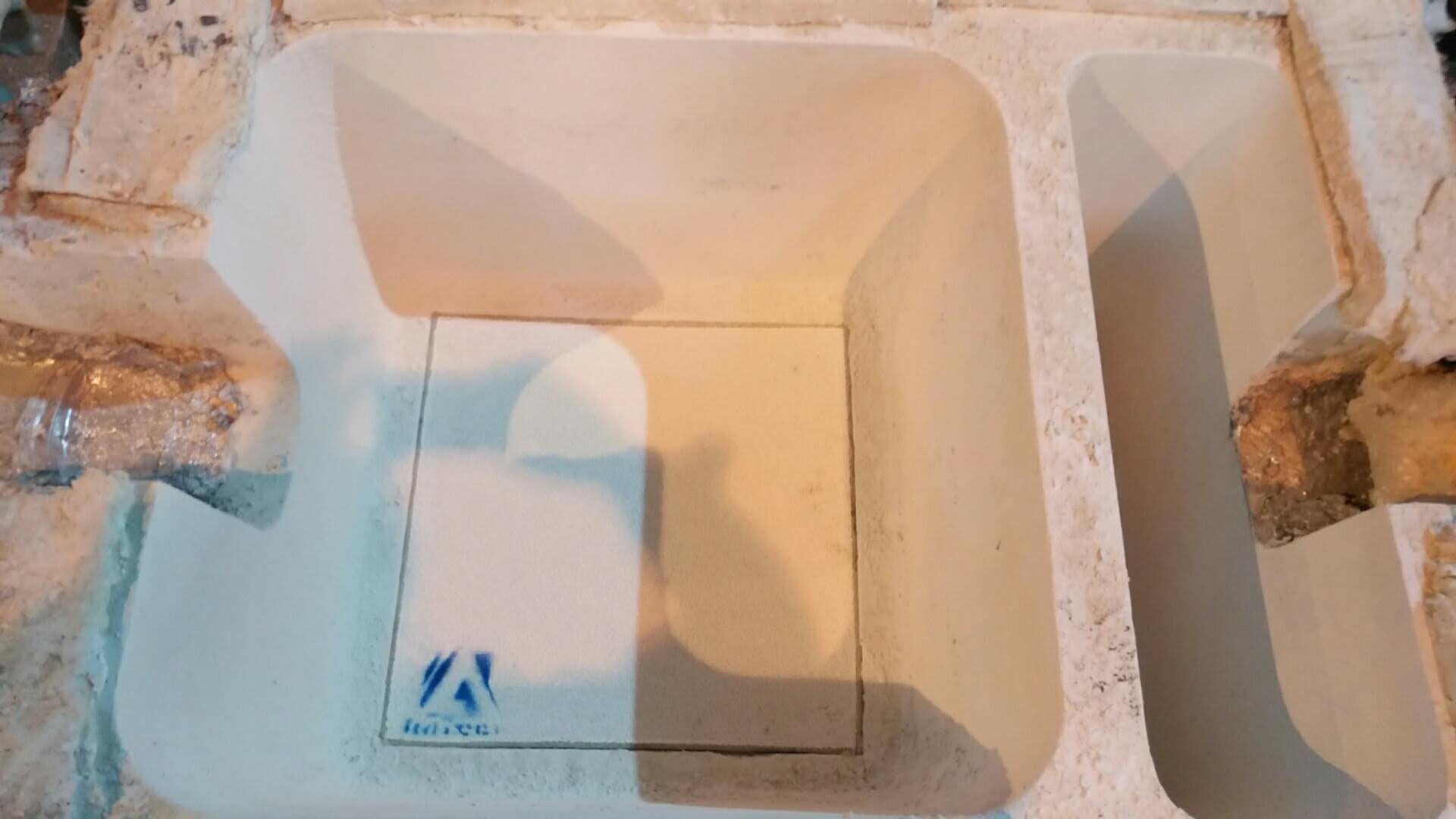

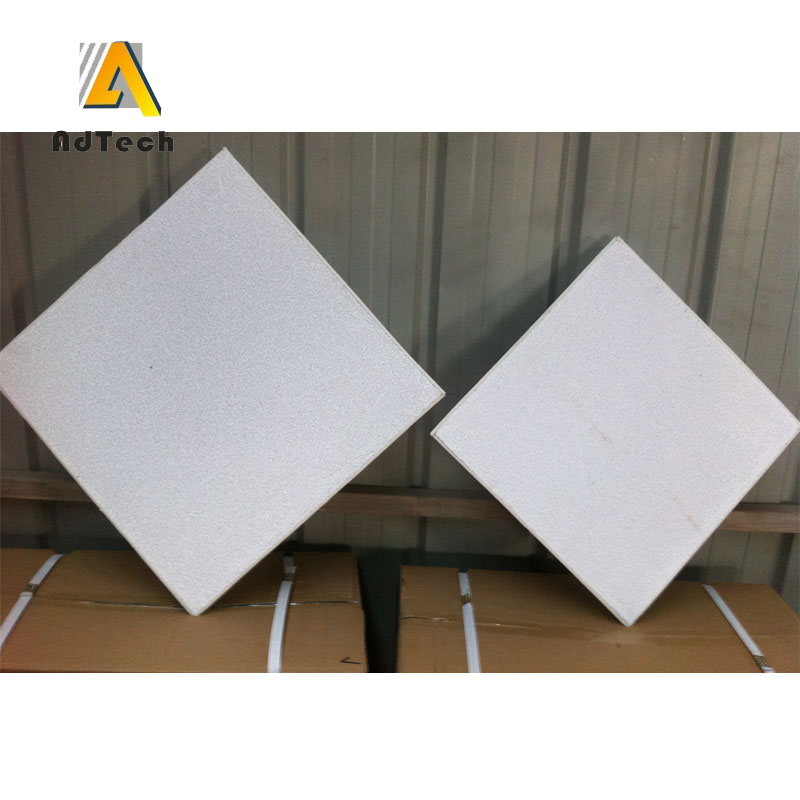

Carried out an extensive programme on Ceramic Foam Filter Aluminum Suriname performance.

In one section of this work the impact of adding a grain refiner based on the Al-Ti-B system was assessed.

They concluded that in case the incoming metal cleanliness was good then there was a minimal impact of the grain refiner on the performance of the filter.

However, if there is an artificially high inclusion loading from the metal (achieved by deliberately vigorously stirring the metal in the furnace), then the introduction of the grain refiner leads to a reduction in filtration efficiency.

In such a case there was a disproportionate release of inclusions from the filter compared to the incoming inclusion levels.

They assumed that the particles exiting the filter are agglomerates of inclusion species arising from the furnace metal interacting with particles from the grain refiner.

Metallographic evaluation of used Ceramic Foam Filter suggests that the bridges of inclusions across the Ceramic Foam Filter Aluminum Suriname cell junctions, as seen in the absence of a grain refiner and do not appear when grain refiner is used.

It has been suggested that the mechanism of filtration of a ceramic foam filter is altered in the presence of a grain refiner addition.

The presence of a grain refiner from the start of casting appears to prevent the formation of bridges within the filter structure.

The introduction of a grain refiner part way through the cast results in the destruction of any previously formed bridges.

It should be made clear that these effects were observed for conditions where the metal inclusion level was artificially high. Under normal conditions the work concluded that the grain refiners have minimal impact on the filter performance.

No Comments