22 8月 Ceramic Filters For Foundry

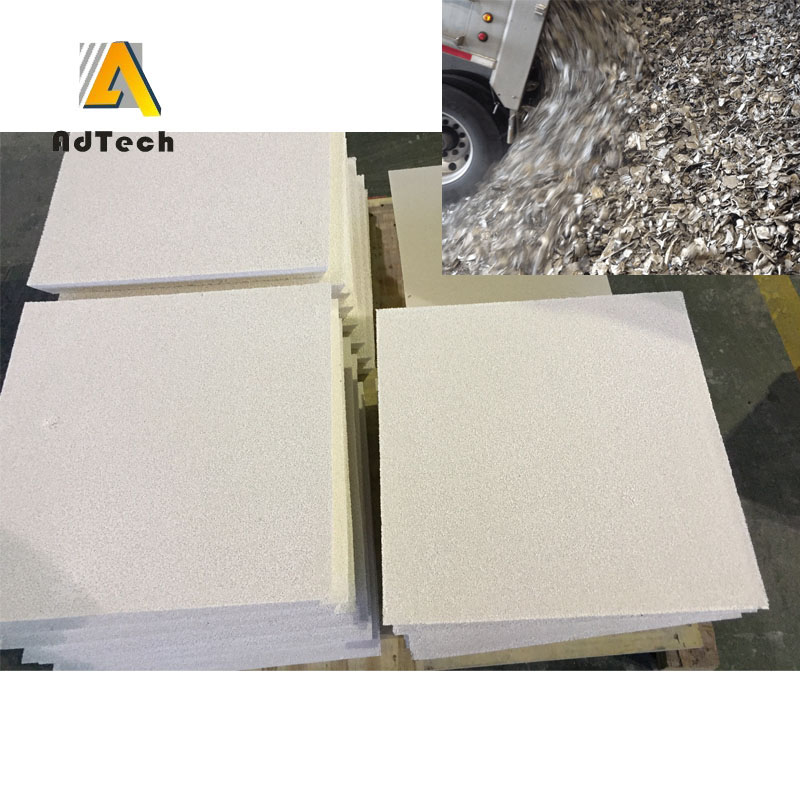

Ceramic Filters For Foundry Description

1>. 3D reticulate structure

2>. High mechanical strength, no-dregs off when flapping

3>. High porosity

4>. Large surface areas, strong absorptivity of impurities

5>. Excellent thermal shock resistance

6>. Rapid improvement in yield

Ceramic Filters For Foundry Application

Filter-PAl ceramic foam filter can effectively remove and absorb large or small impurities in molten aluminum, improve the surface quality, product performance and microstructure effectiveness. Mainly used in the domestic, construction, electricity, condensing tubes, cable and other aluminum alloy precision casting.

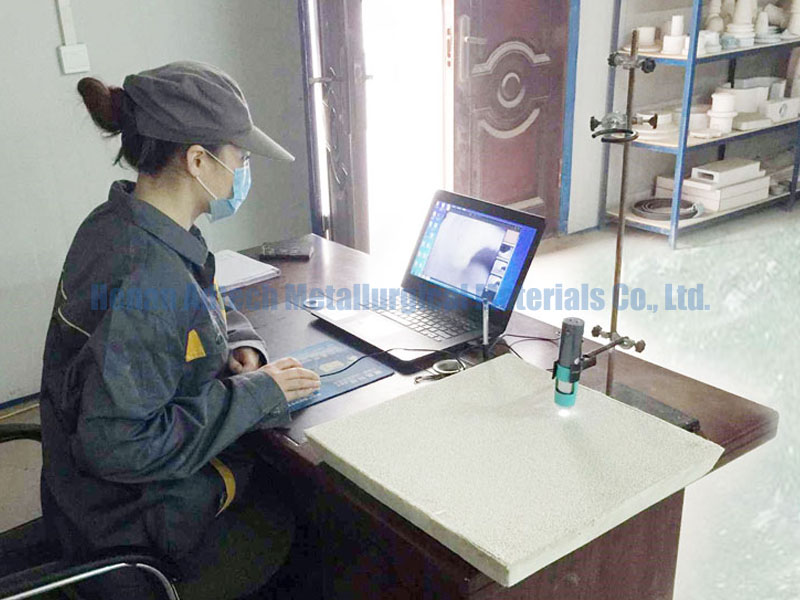

Ceramic Filters For Foundry Reference:

1. Aluminum alloy bar choose: 10-30ppi

2. Long-term casting choose: 30-50ppi

3. High quality aluminum profile or plate choose :40 or 50ppi

4. Double zero wave continuous casting and rolling choose: >50ppi

5. Other specifications can be customized as your requirments

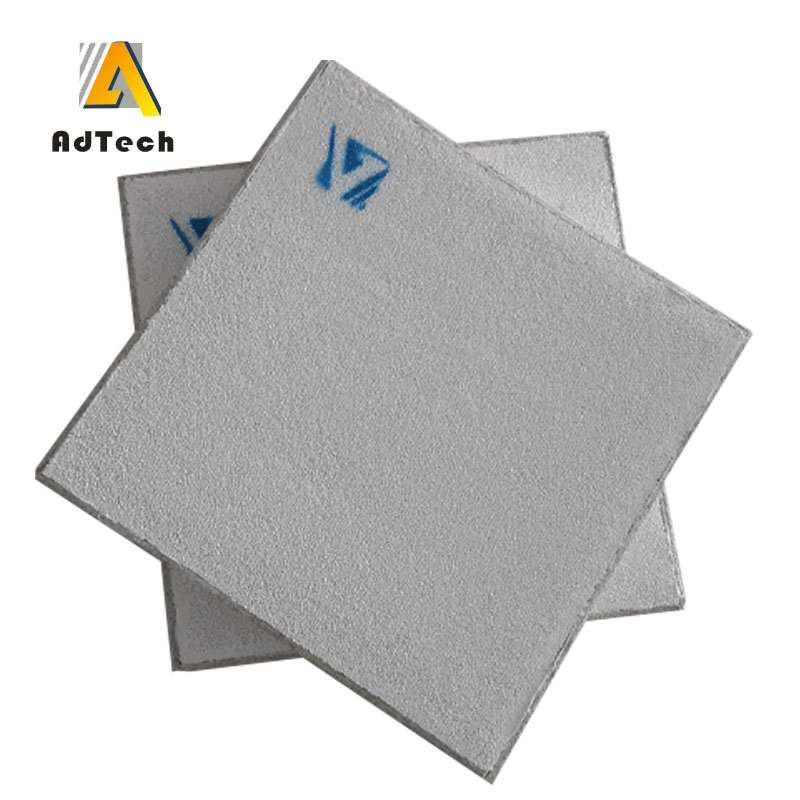

Ceramic Filters For Foundry Advantages:

1.Ceramic Foam Filter used in 3D reticulate structure

2.Ceramic Foam Filter with high mechanical strength, no-dregs off when flapping

3.Ceramic Foam Filter with high porosity

4.Large surface areas, strong absorptivity of impurities

5.Excellent thermal shock resistance>5( at room temperature 750°C)

No Comments