09 11月 Ceramic Filter Dirut Inalum

Ceramic Filter Dirut Inalum is used in the aluminum processing industry, such as electrolytic aluminum plants, strip processing plants, foil processing plants, tubular bar processing plants and recycled aluminum ingot plants.

The quality of aluminum alloy is very important, it greatly affects the performance of the subsequent process and the quality of the final product. Therefore, all countries in the world like the refining of aluminum alloy very much.

During the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state. It is easily oxidized, reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag and coarse intermetallic compound particles.

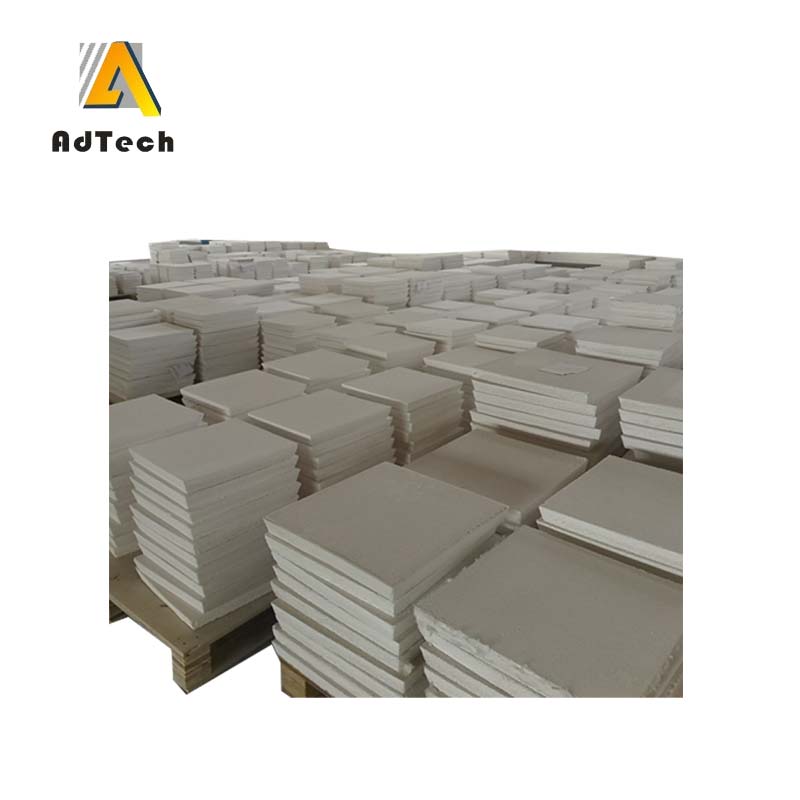

The production process of Ceramic Filter Dirut Inalum

The ceramic foam filter takes the three-dimensional structure and the organic foam sponge connected with the pores as the carrier, infiltrates the special ceramic slurry with thixotropy, and uses a special rolling extrusion process to evenly coat the ceramic slurry on the carrier bone. Then, it is dried and cured, and then fired at a high temperature.

Ceramic foam filter Ceramic filter Aluminum alloy ceramic filter Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Metal Foam Filter uses polyurethane foam as the carrier, immersed it in a layer composed of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruded the excess layer to coat the ceramic layer evenly on the carrier . The bone becomes a green body, and the green body is dried and fired at a high temperature.

terjemahan basa jawa

Keramik Filter Aluminium Jakarta digunakake ing industri pangolahan aluminium, kayata pabrik aluminium elektrolitik, pabrik pangolahan strip, pabrik pangolahan foil, pabrik pangolahan tubular bar lan pabrik ingot aluminium daur ulang.

Kualitas paduan aluminium penting banget, banget mengaruhi kinerja proses sabanjure lan kualitas produk pungkasan. Mulane, kabeh negara ing donya seneng panyulingan paduan aluminium.

Sajrone proses peleburan, aluminium kapapar ing atmosfer ing tungku ing negara molten utawa semi-lebur, iku gampang dioksidasi, reaksi karo uap banyu kanggo nyerep hidrogen, lan gampang mbentuk macem-macem wangun slagsen-awaike interlic.

Proses Produksi Keramik Filter Aluminium Jakarta

Filter busa keramik njupuk struktur telung dimensi lan spons busa organik sing disambungake karo pori-pori minangka operator, nyusup slurry keramik khusus kanthi thixotropy, lan nggunakake proses ekstrusikeramik lan sobong slurries oblong slurries sing disambungake karo pori-pori minangka operator, nyusup slurry keramik khusus kanthi thixotropy, lan nggunakake proses ekstrusikeramik sing dhuwur.

Filter umpluk Keramik Filter Keramik Aluminium alloy Filter Keramik Wiwit riset pisanan ing 1978, teknologi filtrasi Keramik umpluk wis dikembangaké kanthi cepet.

Filter umpluk Keramik keropos nggunakake umpluk polyurethane minangka operator, nyemplungaken ing lapisan dumadi saka wêdakakêna keramik, Binder, sepindah sintering, suspending agen, etc., lan banjur extruded lapisan kelu-banjur extruded lapisan kelu-rohan kanggo roami kanggo roaming operator, kanggo roamik kanggo rookie awak ijo wis garing lan dipecat ing suhu dhuwur.

No Comments