31 10月 Ceramic Fiber Launder

Ceramic Fiber Launder

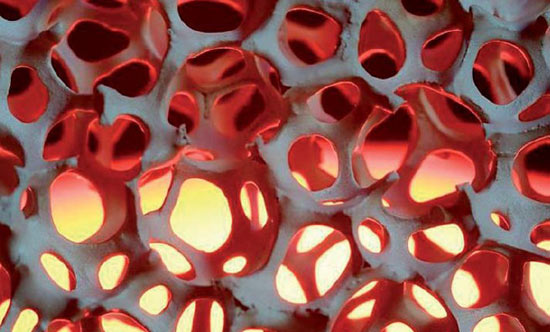

Ceramic Fiber Launder is mainly used for the transportation of molten aluminum and aluminum alloy. The product has the characteristics of good heat insulation performance, non-stick aluminum and erosion resistance. The Launder made by the ceramic fiber has a large temperature drop during the long-distance transport of aluminum liquid. We recommend the use of refractory fiber flow trough instead, and can be combined with the use of refractory fiberboard as a cover plate, which can greatly reduce the loss of thermal energy.

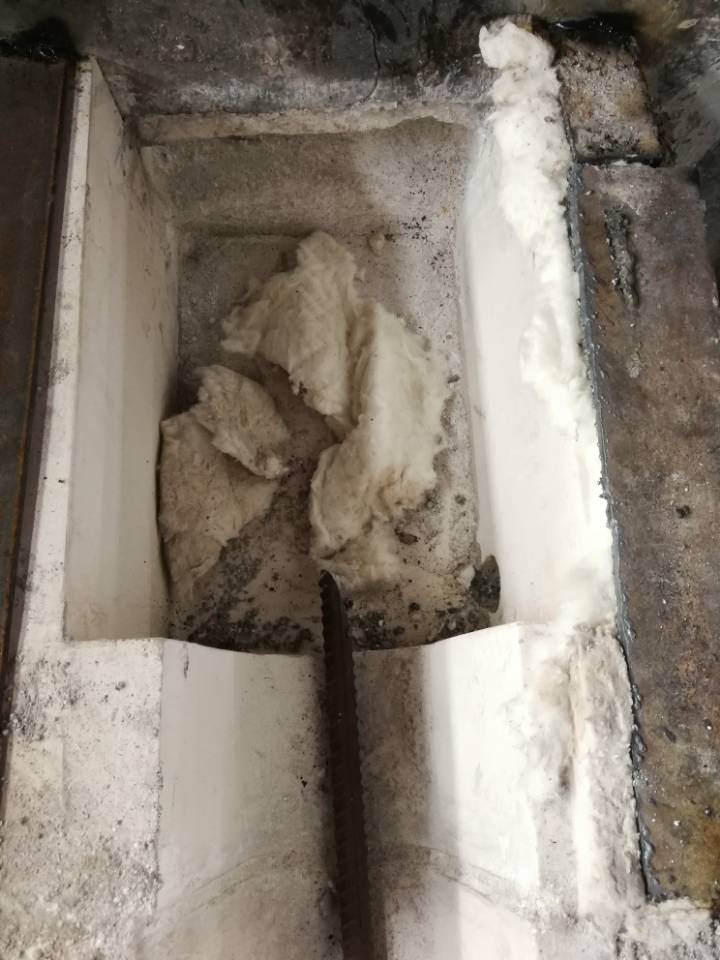

If the Ceramic Fiber Launder is damaged, it can only be removed and re-casted; and the ceramic fiber active launder can be repaired with our fibers, and timely repair and maintenance can extend the service life of the launder.

The Aluminium Launder of fiber ceramic materials will be widely used in various occasions in foundry factories. The drawing is a ceramic fiber flow cell with excellent non-stick aluminum characteristics, no aluminum hanging, and low heat absorption. No pollution to the product. The surface of the product is dense and smooth, such as enamel, high strength and light weight. Special materials that are completely non-wetting with aluminum, used in combination with BN coatings, are excellent in non-stick aluminum properties.

Ceramic Fiber Launder can be processed according to customer’s requirements and is suitable for different working temperatures. It mainly serves as a bridge for aluminum water to flow through.

Ceramic fiber Launder Features: tough texture, strong wind erosion resistance; seamless lining; low heat storage, heat loss; direct contact with flame for hot surface; excellent construction and installation performance; excellent thermal shock resistance; High compressive strength and long service life; significant sound absorption.

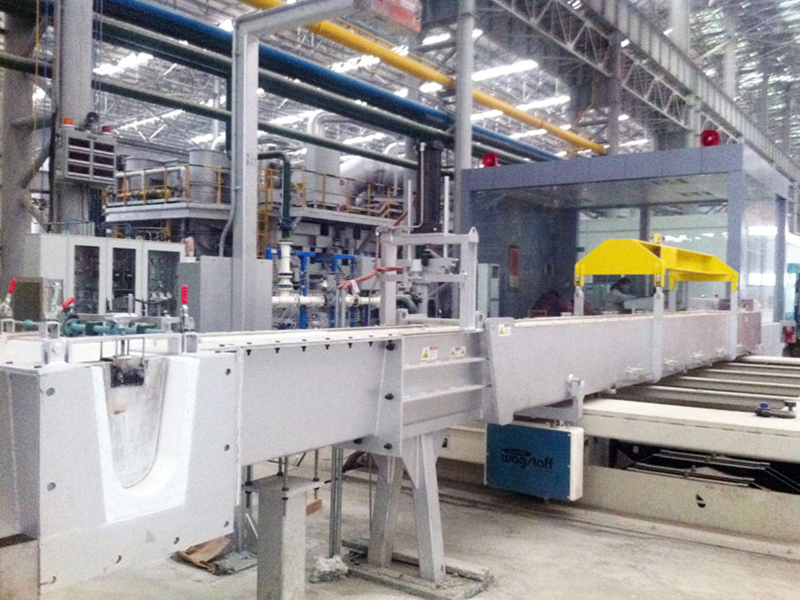

Ceramic Fiber Launder AdTech is a manufacturer which is specialized in the development of new material and production of high-performance insulation sealing. Since 2012, our company has started to R&D overall launder, degassing unit and plate filtration unit. Supply integration services in high-precision aluminum alloy casting. Got good reputation in market.

sales@adtechamm.com

The integrated launder unit is installed between the furnace and the casting machine and it has dual function: transportation and insulation. Mainly used in the transportation of molten aluminum between furnace, purifying furnace, casting platform, degassing unit and filtrating unit for the aluminum precision casting. It is suitable for casting such aluminum materials as below stated: computer hard drive, micron-grade aluminum foil, PS board, canning materials, fan blades of jet turbine engine, etc.

No Comments