23 3月 Casting knowledge – float flow control device

Casting knowledge – float flow control device

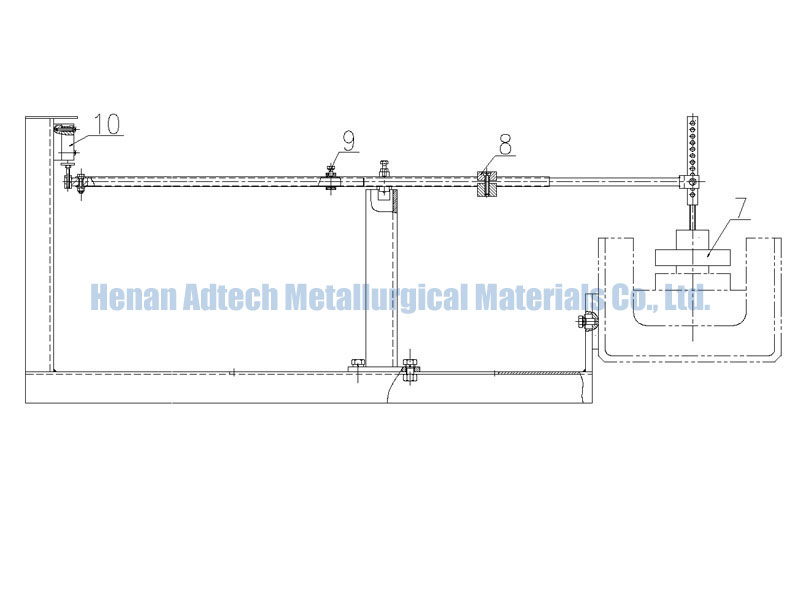

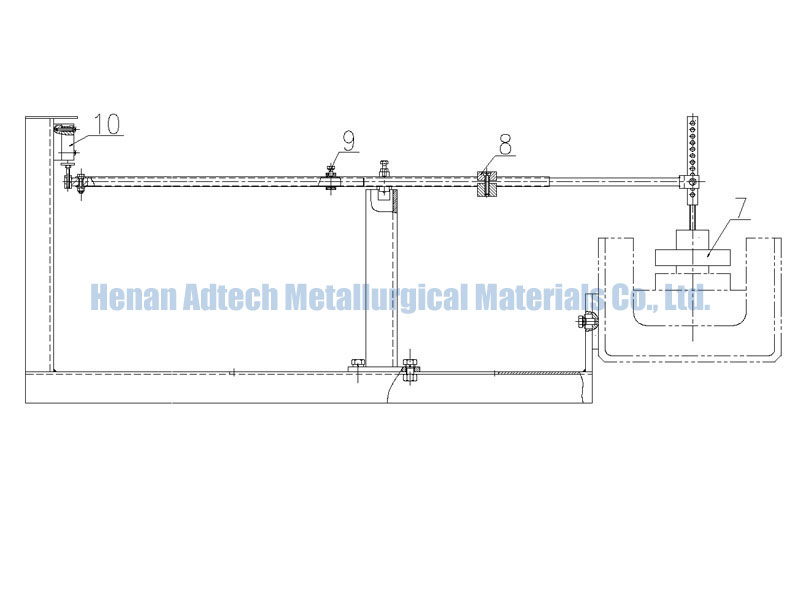

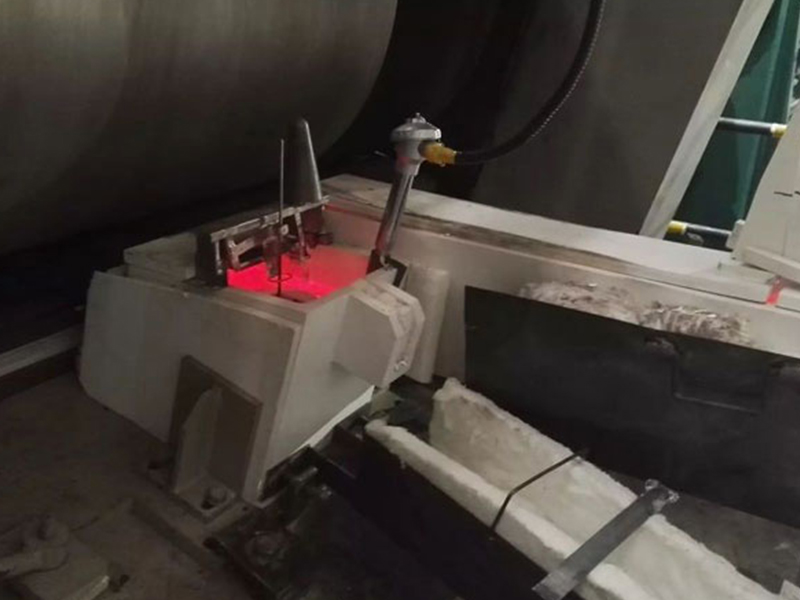

1. The liquid level in the trough is controlled by the liquid level control device (see the figure above). When the liquid level in the trough reaches the target liquid level (the level of the liquid required by the process), the height of the float No. 7 is adjusted, and the position of the No. 8 and 9 counterweights is adjusted so that the lever mechanism is in an equilibrium state. In this state, the position of the tapping rod of the furnace flow control device is adjusted. Piece 10 mechanical valve is open.

Casting knowledge – float flow control device

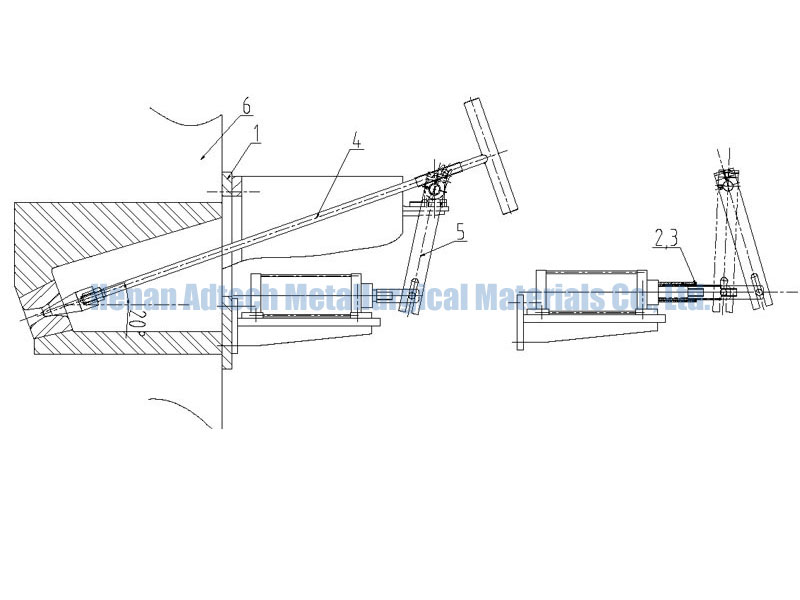

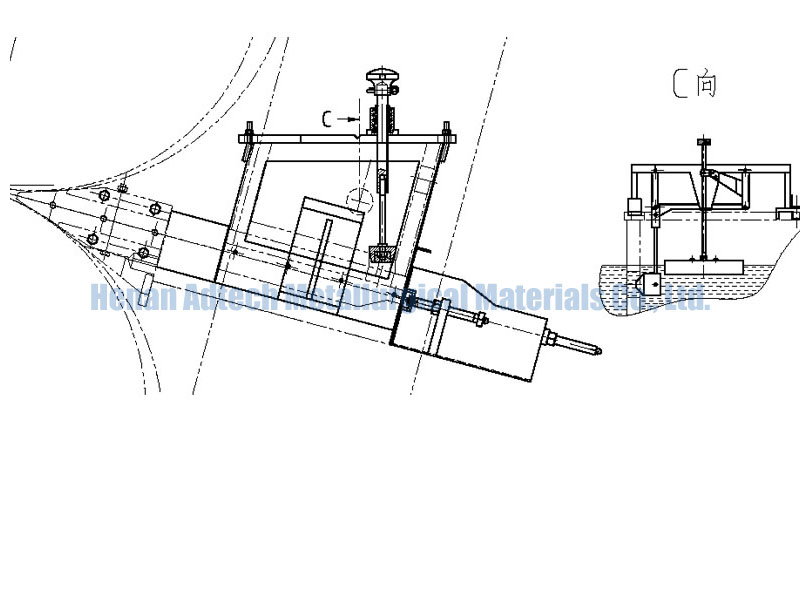

2. The flow control device base plate (No. 1) is welded on site and rested on the furnace wall. After the position of the stopper rod (No. 4) is fed back by the liquid level control device, the position of the stopper rod at the furnace mouth is initially determined, and the angle of the swing arm (No. 5) is adjusted, and the cylinder is in an extended state. When the liquid level decreases, the float decreases with the liquid surface, causing the lever to push the mechanical valve needle back, and the mechanical valve controls the cylinder movement. As the cylinder is retracted and the tappet rod is opened, the flow rate of molten aluminum is increased, so that the aluminum liquid in the flow cell is replenished and the liquid level fluctuation is kept within ±3 mm. The stroke of the cylinder can be adjusted to meet the production requirements by adjusting the limiting sleeve (No. 2 and No. 3), and the stroke of the tapping rod can be controlled.

No Comments