15 5月 Alumina Ceramic Foam Filter Australia

Alumina Ceramic Foam Filter Australia is installed in CFF BOX Machine, used to filter aluminum alloy liquid impurities, to meet the high value-added, high technical performance aviation, transportation and other aluminum alloy precision casting production.

Such as: computer hard disks, printed PS board bases, materials that can be made, jet turbine engine fan blades and other products. We Evans is a professional manufacturer of aluminum foam filter plate

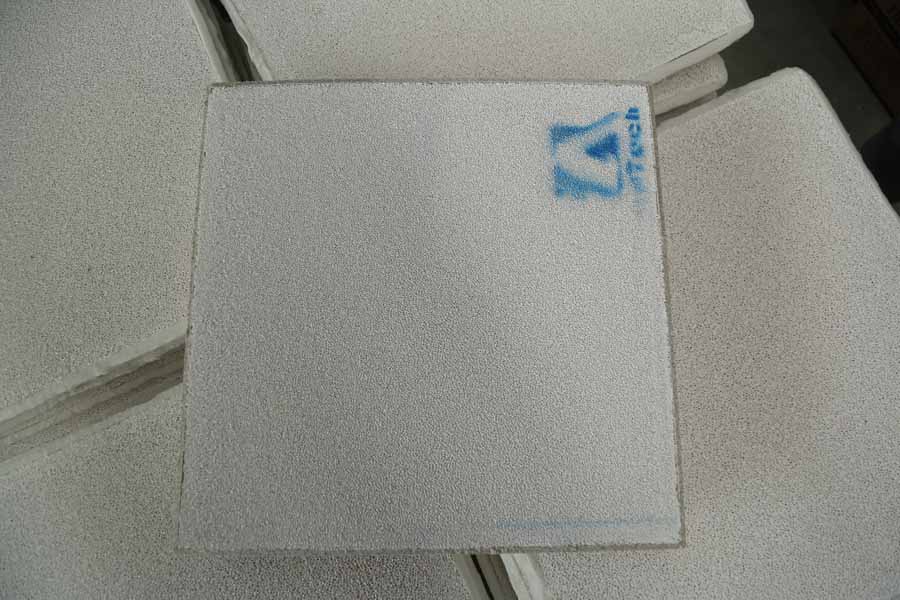

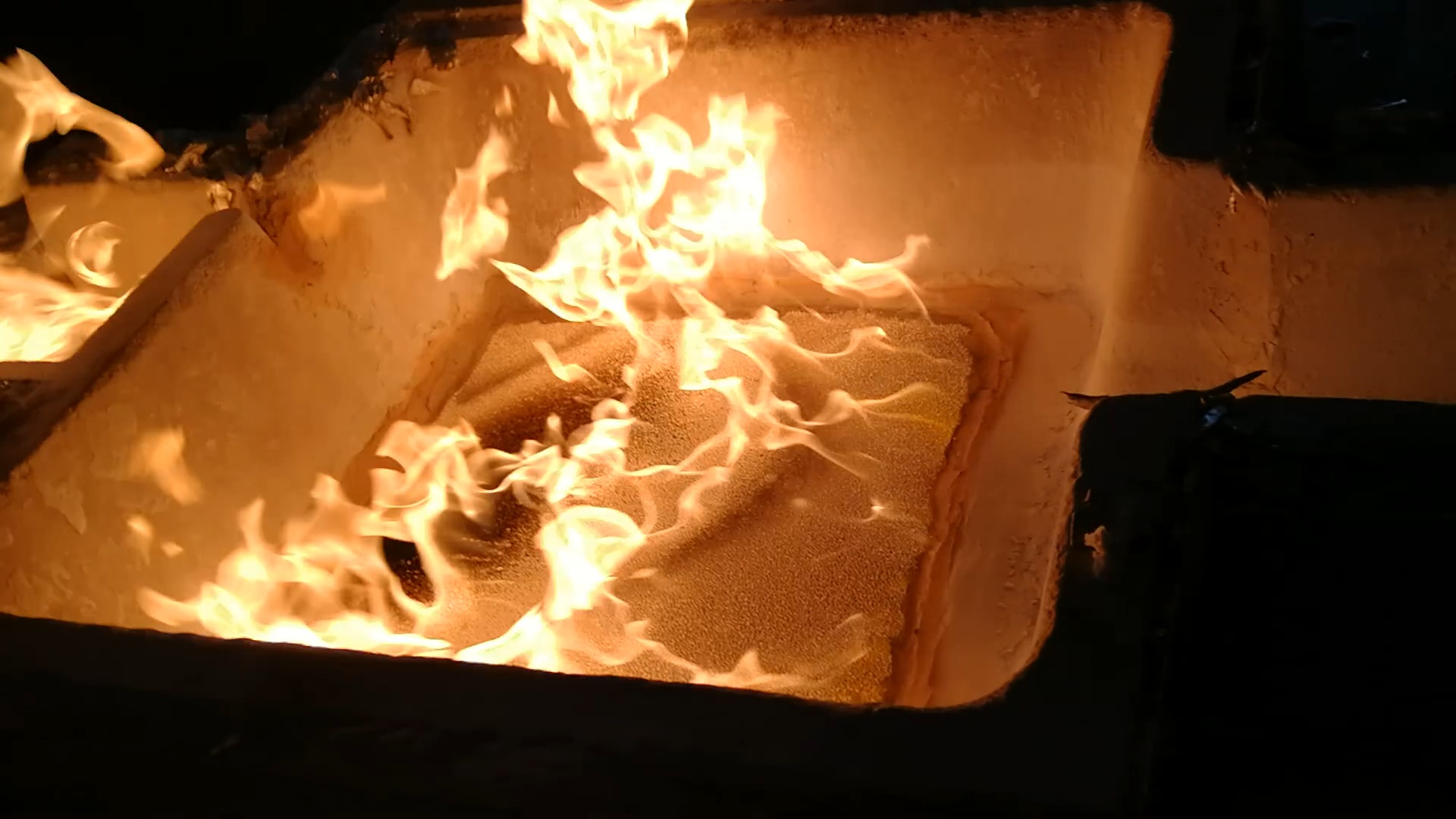

Alumina Ceramic Foam Filter Australia uses a three-dimensional network structure with organic foam connected to the pores as a carrier to invade the thixotropic alumina slurry. The slurry is evenly coated on the foam skeleton of the carrier and baked and cured at a high temperature of 1180 ° C.

Alumina Ceramic Foam Filter Australia product advantages

1. Adopting the principle of adsorption filtration to remove large inclusions in the aluminum liquid, effectively adsorbing small inclusions of small size.

2. No slag, effectively reduce aluminum liquid pollution.

4.Good thermal shock resistance and corrosion resistance of molten metal.

5. Automated assembly line production, three calibration procedures, accurate size, more in line with filter box.

6. Improve surface quality, improve product performance, and improve the role of microstructure.

Alumina Ceramic Foam Filter Australia User Manual

1. Check and clean the debris on the surface of the filter box to keep the filter box clean and free from damage.

2. Gently put the filter plate into the filter box and press the seal around the filter plate with your hand to prevent the aluminum liquid from flowing or floating.

3. Preheat the filter box and the filter plate evenly so that it is close to the temperature of the molten aluminum. The preheating temperature of the filter plate is not lower than 260 ℃. Preheating removes the absorbed water, which helps the initial opening of the filter hole and prevents some of the holes on the filter plate from being blocked by thermal expansion and contraction. Preheating can use electric heating or gas heating, normal heating for 15-30 minutes.

4. Observe the changes of the aluminum hydraulic head during the aluminum casting process to maintain the control flow of the normal demand aluminum liquid. The normal starting head is 100-150 mm. When the molten aluminum begins to pass, the indenter will fall below 75-100 mm, and then the indenter will slowly increase.

5. When filtering frequently, avoid knocking and shaking the filter plate. At the same time, the tank should be filled with aluminum water to avoid interference of too large or too small aluminum liquid.

6. After filtering, remove the filter plate in time and clean the filter box.

Storage of foam ceramic filter plate in aluminum factory: It should be stored in a ventilated and dry environment to prevent moisture, and no objects should be placed on it.

Alumina Ceramic Foam Filter Australia can be used inPacific Aluminum, Pacific Aluminum Company, Aluminum Pacific, Pacific Coast Aluminum Products, Aluminium Pacific, Fletcher Aluminium Pacific Suite, Pacific Aluminium Bell Bay, New Zealand Aluminium, New Zealand Aluminum, New Zealand Aluminium Smelters(Nzas), New Zealand Aluminium Smelters Jobs, New Zealand Aluminium Smelters, New Zealand Aluminium Smelters Invercargill, New Zealand Aluminium Smelters Limited (Nzis), New Zealand Aluminium Smelters Ltd, New Zealand Aluminium Smelters Limited, New Zealand Aluminium Smelters (Nzas), New Zealand Aluminium Smelter Limited, New Zealand Aluminum Smelter, New Zealand Aluminum Catamaran, New Zealand Aluminum Company, New Zealand Aluminum Smelters Ltd, Aluminum Jobs In New Zealand, Nz Aluminium, Nz Aluminium Smelter, Nz Aluminium Supply Co Ltd, Nz Aluminium Cladding, Nz Aluminium Smelters Limited, Nz Aluminium Smelter Invercargill, Nz Aluminium Smelters Ltd, Aluminium Smelter Bluff Nz, Aluminium Smelter South Island Nz…

Sorry, the comment form is closed at this time.