23 8月 Performance of Adtech flexible graphite rings

We may be able to use flexible graphite packing rings frequently, but do we really know about it? Today, I will write an article about the introduction of flexible graphite packing rings, so that everyone can have a better understanding of flexible graphite rings.

Features of flexible graphite rings:

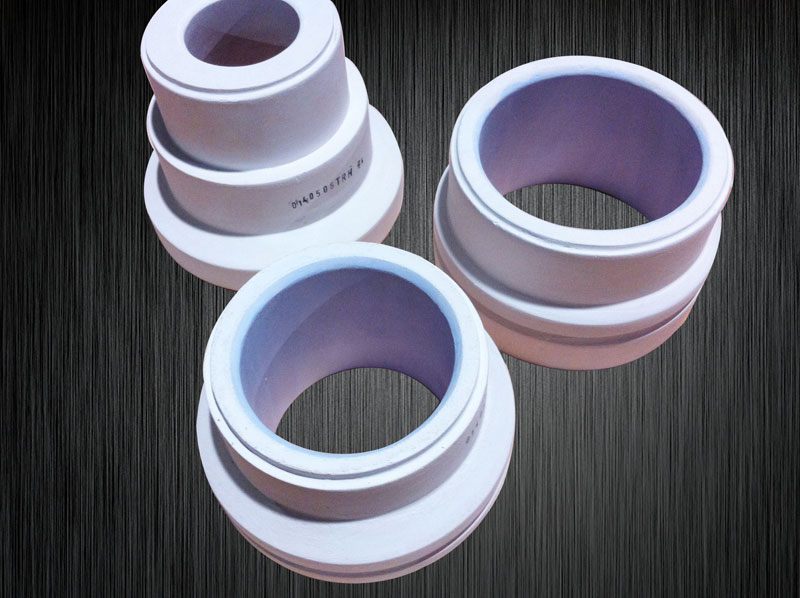

Self-sealing flexible graphite ring, also known as self-sealing graphite packing ring. A ring made of pure flexible graphite paper. After cutting, the graphite paper is spirally wound into a ring-shaped graphite packing at an angle of 45 degrees, which can be used to seal the upper and lower end faces of the stuffing box, especially for the sealing of high temperature and high-pressure components, such as those commonly used in power systems. 45-degree angle inclined self-cushion. According to customers’ requests, metal edges and upper and lower-end corners can also be wrapped.

It is annular graphite packing made of pure flexible graphite paper. After cutting, the graphite paper is helically wound and pressed into a die. The size is accurate, the density can be determined, the purity of graphite is more than 99%, and there is no additional filler or binder. The surface can also be treated with corrosion inhibitors such as zinc powder. The general section is square or wedge-shaped V-shaped, and the latter two are suitable for high-pressure parts.

1. The flexible graphite ring has excellent high-temperature resistance and corrosion resistance.

2. The flexible graphite ring has good self-lubrication.

3. The flexible graphite ring has a high rebound coefficient.

4. The flexible graphite ring can be cut with a 45° oblique cut according to user needs.

The above is a brief introduction to flexible graphite packing rings, I hope it can help you. For an in-depth understanding, you can contact Langfang Dasheng Sealing Materials Co., Ltd., specializing in the production of flexible graphite rings.

No Comments