14 Jul Casting Launders

Casting Launders

The aluminum launder is one of the basic equipment for aluminum alloy casting.

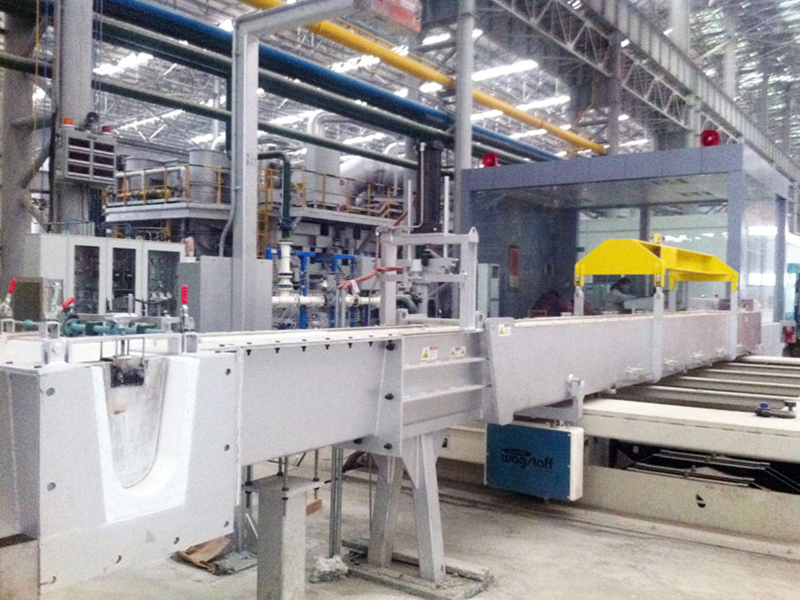

The main function of the fixed launder with shell is to drain the aluminum liquid from the mixing furnace to the casting machine.

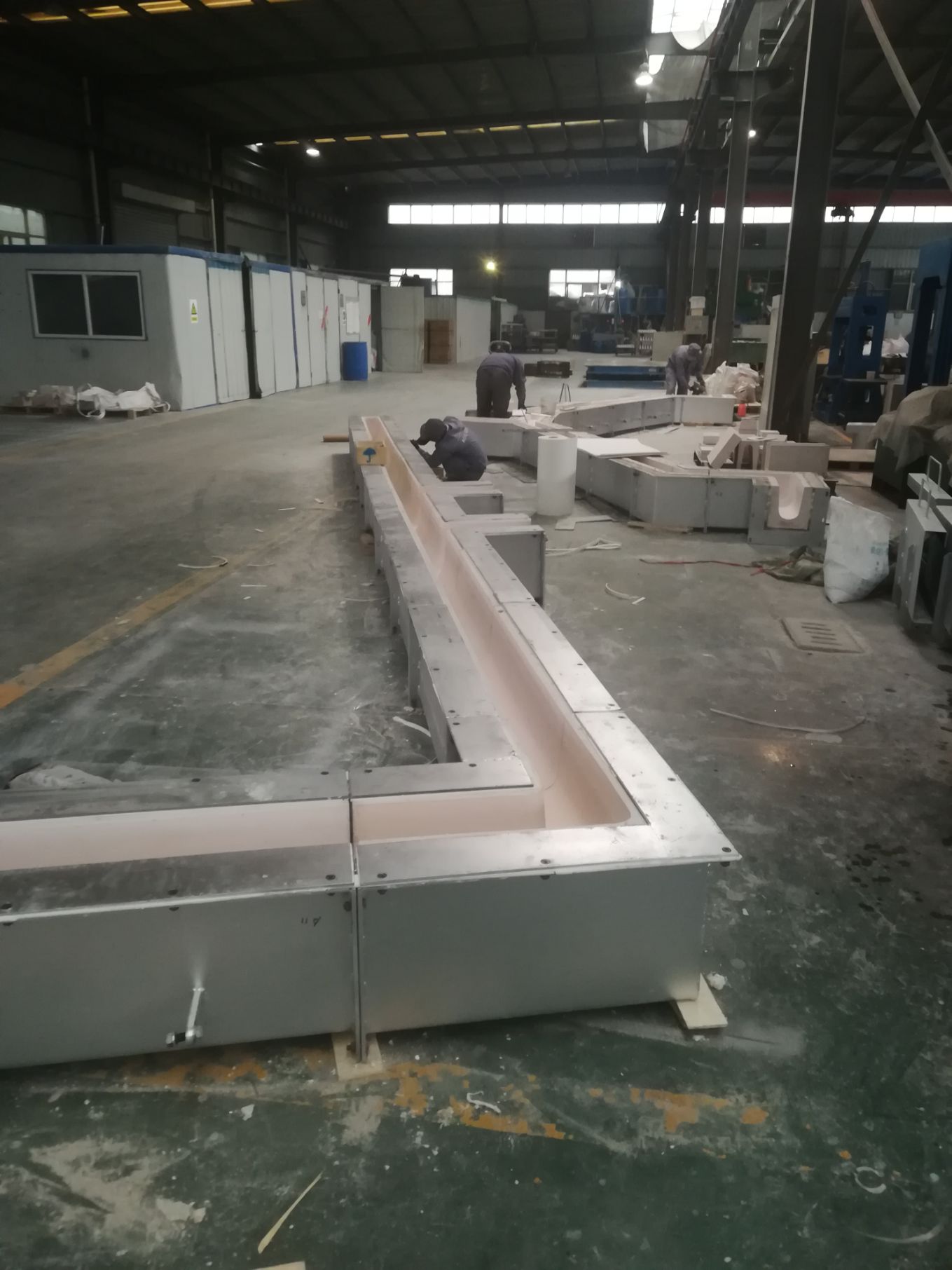

Process design of a laundromat with a shell.

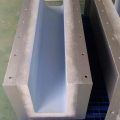

Casting Launder Inner lining design

ULTRA-CAST FS is designed for the aluminum processing industry and is used for the working lining of the parts of aluminum liquid transfer and processing equipment, such as aluminum liquid transfer Launders and filter boxes that are in direct contact with aluminum liquid. It can also be used as the lining material for aluminum liquid insulation furnaces and aluminum ladle linings. Fused quartz is used as the main raw material, and the excellent volume stability of fused quartz material is utilized; in addition, ULTRA-CAST FS is added with anti-sticking aluminum additives to prevent aluminum liquid from penetrating, so that the entire material has excellent anti-aluminum adhesion performance, and its special design makes the casting surface smoother;

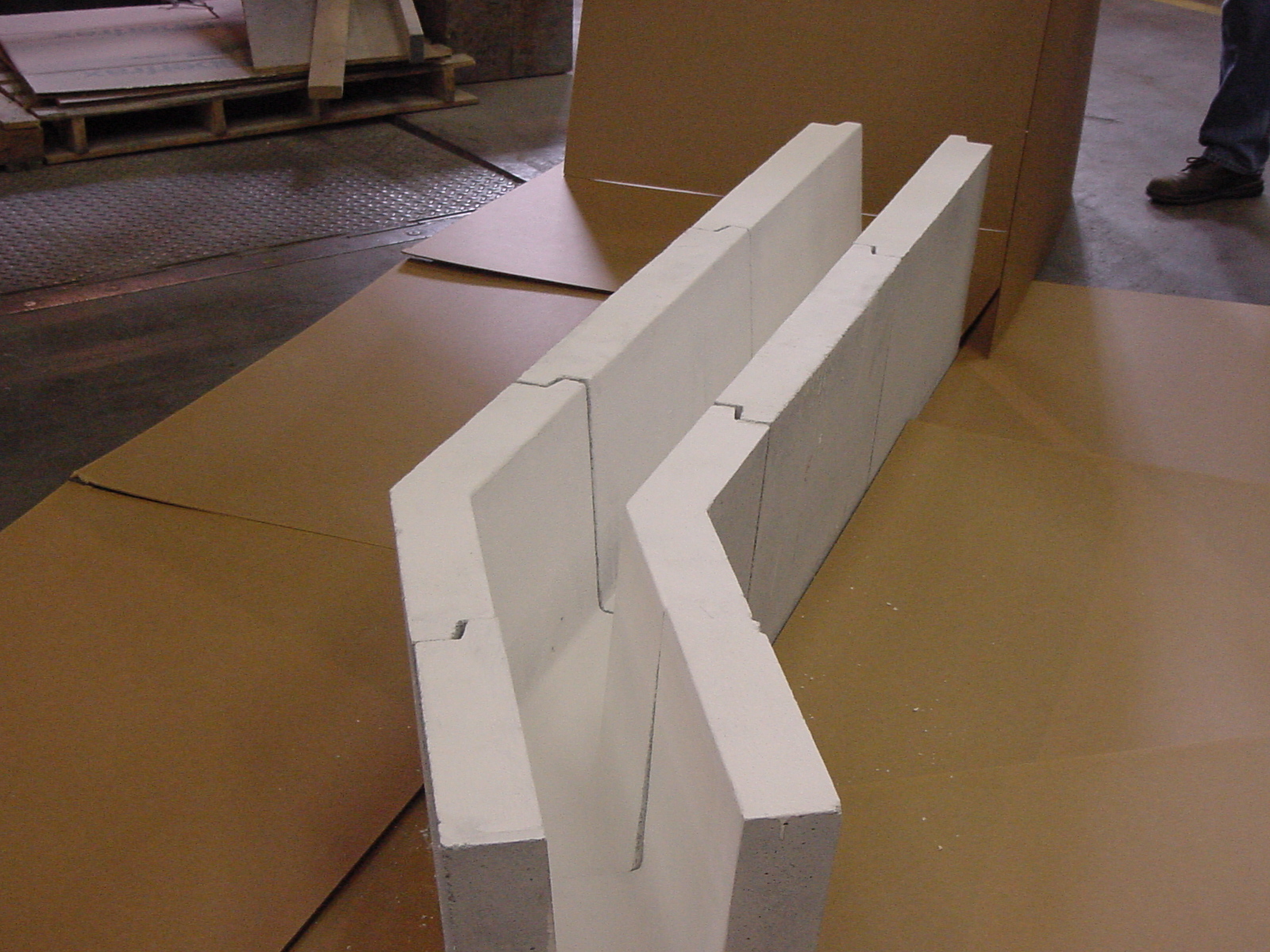

Casting Launder Shell fixed runner high temperature resistant insulation special-shaped parts

1. Made of high-quality ceramic fiber cotton as raw material and vacuum forming process, the purpose of developing this product is to manufacture rigid, special-shaped parts with excellent high temperature performance and self-supporting strength.

2. High temperature resistant and heat-insulating shaped parts are all shaped products that meet the specific production links of specific industrial sectors. Each product needs to make a special mold according to its shape and size, and add additives to meet specific use requirements.

* All heat-resistant and heat-insulating molded products have low shrinkage within their use temperature range, and maintain high insulation, light weight, and impact resistance. Unheated materials are easy to cut or process during use. Medium hardness products have good wear resistance and peeling resistance, and will not be wetted by most molten metals.

Advantages:

Adtech Casting Launders have high overall strength, high unit volume density, a trough-shaped inner cavity, high temperature refractory coating, non-stick aluminum, and internal slag that is easy to clean.

There is no damage or cracking within three years under high temperature conditions, and there is no aluminum leakage at the Casting Launder interface and bottom, eliminating the safety hazard of aluminum leakage at the Casting Launder. The shutdown time for cleaning the trough is reduced by 20 minutes, reducing the labor intensity of aluminum workers.

Sorry, the comment form is closed at this time.