22 Jan How to reduce molten aluminum dross

How to reduce molten aluminum dross

When we melt aluminum, it will form dross aluminum oxide. how to reduce it back to aluminum, then?

Update: reduce here DOES NOT mean to reduce the amount of dross, but to CHANGE Aluminium oxide to aluminum. Molten Aluminium Dross Reduction

How to reduce aluminum loss in the melting

There are many methods for aluminium dross recycling; also reducing the aluminium dross in production is a direct method to save the aluminum loss. At the same time, it can save energy for the coming dross recycling; it is the most direct one of the methods to save energy.

The main reason for aluminium dross formation is the reaction resulting between high-temperature liquid aluminum and air in aluminum melting and molten aluminum conveying processes. In the formation, the conveying and stirring, etc external mechanical forces will promote the reaction, so dross generation intensified in this process.

Molten Aluminum Dross Reduction?

How to control Molten Aluminium Dross Reduction:

There are many methods for aluminium dross recycling; also reducing the aluminium dross in production is a direct method to save the aluminum loss. At the same time, it can save energy for the coming dross recycling; it is the most direct one of the methods to save energy.

The main reason for aluminium dross formation is the reaction resulting between high-temperature liquid aluminum and air in aluminum melting and molten aluminum conveying processes. In the formation, the conveying and stirring, etc external mechanical forces will promote the reaction, so dross generation intensified in this process.

We can use refining agents to refine aluminum Refining Flux

Aluminum refining agents play many important roles in aluminum alloy production, mainly including removing impurities, preventing gas desolvation, improving fluidity, and increasing purity.

Aluminum refining fluxs can remove harmful substances such as gases, oxides, impurities, etc. in aluminum liquid, especially the most common gas hydrogen, thereby avoiding the formation of bubbles and pores in the alloy, which affects the quality and performance of the aluminum alloy. In addition, the refining agent can reduce the surface tension of the aluminum liquid, improve the fluidity of the aluminum liquid, which is beneficial to the filling of the mold during the casting process, and significantly improve the purity of the aluminum liquid and the quality of the casting.

We can take the following measures to reduce aluminium dross generation:

1 Reasonable furnace physical dimension and charging sequence

The design and production of most melting and casting workshops is adopting a fixed melting furnace. In the melting and casting process, the aluminum water will be from one level to another level in the Garret-type layout, so the molten aluminium surface oxide layer will break in the aluminium water discharging, which will cause a considerable quantity of aluminium dross. In addition, the improper furnace door, will cause aluminium loss, and aluminium dross is formed.

2 Control the reasonable melting temperature to shorten molten aluminum conveying and melting time

The conveying and melting time extends the contact time between liquid aluminum and air. That means it extends the reaction time between molten aluminum and air. The higher the temperature, the longer the melting time is, and the more aluminum loss will be. Only if the contact between molten aluminum and air is limited or the surface aluminum dross temperature is cooled rapidly can it make a continuous reaction.

3 Choose the proper operation

Try to keep the molten aluminum surface oxide film intact during stirring and cover the molten aluminum promptly. Stirring causes oxidation and thermite reaction, which is an important reason for aluminum loss.

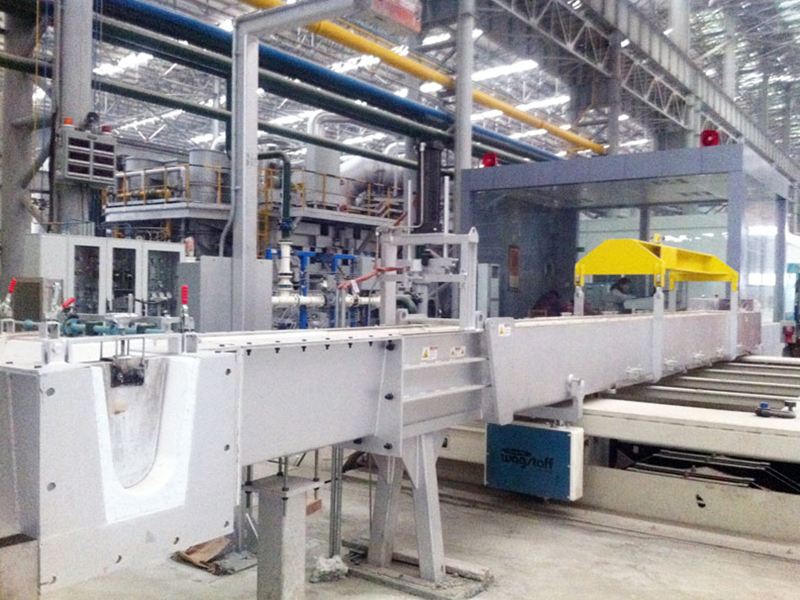

It is impossible to completely avoid aluminium dross in production, and the Aluminium dross product is not entirely waste material. It can be recycled or used in secondary steelmaking for slag deoxidation. You can try an aluminium dross processing machine to separate aluminum from aluminium dross.

No Comments