02 8月 Zirconia Ceramic Filte

Zirconia Ceramic Filte

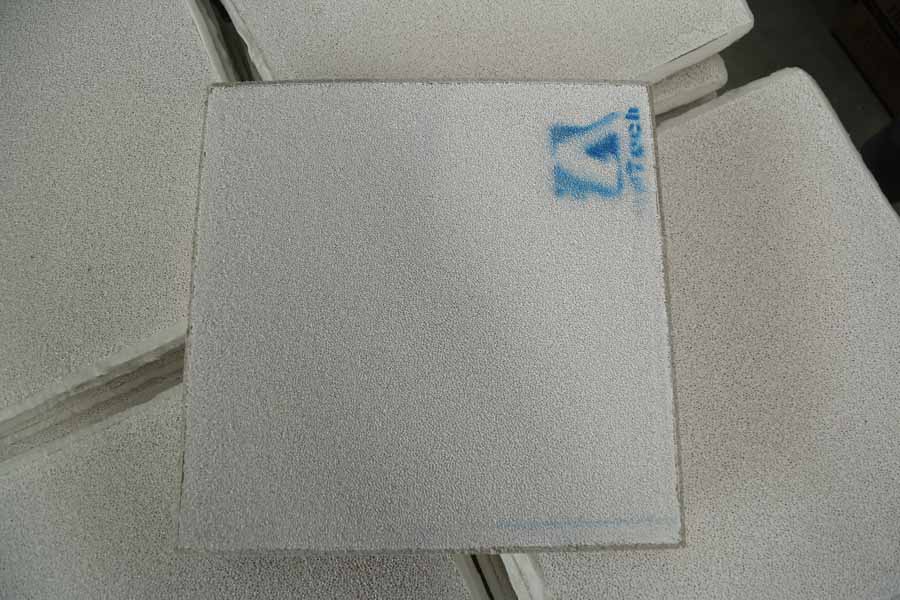

Zirconia Ceramic Filte Using three-dimensional network structure and connected pores organic foam as a carrier and immerse into thixotropic special ZrO2 molten material slurry, using four correction center distance and automatic extrusion, the slurry evenly deposited in the foam, after 1320 ℃ Drying and solidification.

Zirconia Ceramic Filte Product Description

1.Using three-dimensional network structure

2.Connected pores organic foam as a carrier and immerse into thixotropic special ZrO2 molten material slurry

3.Using four correction center distance and automatic extrusion

4.The slurry evenly deposited in the foam, after 1680 ℃ Drying and solidification

5.Ceramic foam filter completed

6.There is expansive cotton for sealing at the edge

Zirconia Ceramic Filte Application

Zirconia Ceramic Filte can effectively remove and absorb large or small impurities in molten aluminum, improve the surface quality, product performance and microstructure effectiveness. Mainly used in aviation, transportation and other aluminum alloy precision casting.

Zirconia Ceramic Filte Performance

Filter-PZr ceramic foam filter can effectively remove and absorb large or small impurities in molten aluminum, improve the surface quality, product performance and microstructure effectiveness. Mainly used in the domestic, construction,electricity, condensing tubes, cable and other aluminum alloy precision casting.

Zirconia Ceramic Filte Product Feature

1.Aluminum alloy bar choose: 10-30ppi

2.Long-term casting choose: 30-50ppi

3.High quality aluminum profile or plate choose :40 or 50ppi

4.Double zero wave continuous casting and rolling choose: >50ppi

5.Other specifications can be customized as your requirments

Zirconia Ceramic Filte Usage

1.Clean the aluminum filter box, keep it clean and intact.

2.Put the ceramic foam filter into filter box carefully , press Sealing gasket around , avoid molten aluminum Dispersing or floating away.

3.Use electric or gas to Preheat filter box and ceramic foam filter evenly 15-30min, make the temperature next to 5.the molten aluminum, ceramic foam filter preheating temperature should surpass 460℃.expansion cotton will seal after heating, it makes ceramic foam filter steady in molten aluminum. preheating makes ceramic foam filter pores open and avoid occlusion expansion and contraction.

Observe change of molten aluminum pressure, control the flowing molten aluminum needed, normal start pressure: 100-150mm. the pressure falls down bellow 75-100mm when molten aluminum flowing, it will grow later.

4.Do not shock and beat ceramic foam filter in filtration. Control molten aluminum flow rate in launder.

5.Take out ceramic foam filter and clean filter box after filtration.

Sorry, the comment form is closed at this time.