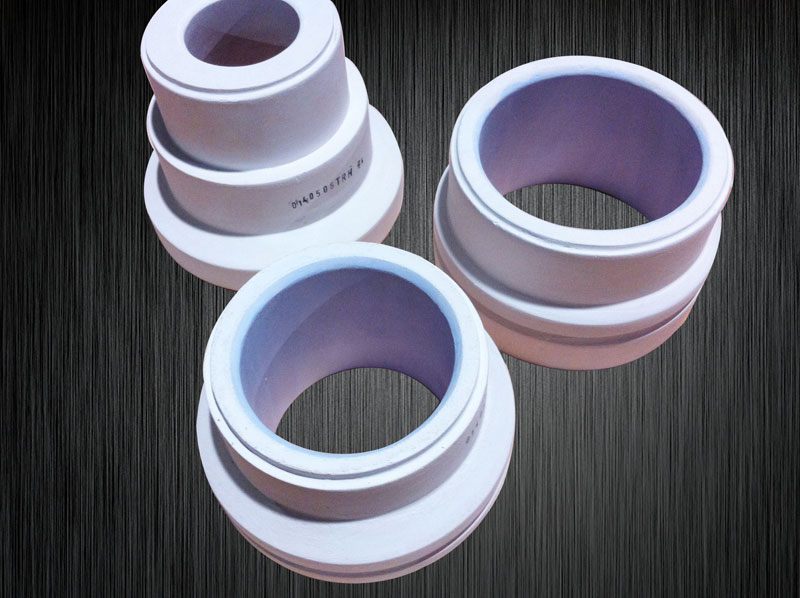

02 11月 Riser Sleeve

Riser Sleeve is made of two materials of high silicon melting 140 and Al-Si. It has strong corrosion resistance, high geometric accuracy, smooth casting surface, long life, low maintenance cost, and no pollution to molten metal. It is the best choice for hot top casting , To meet the technical needs for the production of aluminum alloy precision casting products such as aviation, transportation, and electronic products that require high added value and high technical performance.

Hot-top casting refers to a casting method in which there is a section with good heat preservation performance on the top of the mold, which is used to slow down the primary cooling of the upper part of the mold, rather than slow down the primary cooling of the entire mold. Riser Sleeve is one of the more important parts before molten aluminum enters the crystallizer.

Choose the hot top casting equipment platform installation accessories of the corresponding specifications

Install the shunt plate, sleeve, adapter plate, shunt groove, and graphite ring on the upper side of the platform.

The casing, the adapter plate, and the graphite ring are installed inside the mold to ensure cleanliness, no damage, and no gaps.

It is best to use ceramic fiber paper or ceramic fiber blanket to seal the sides and bottom to help heat preservation.

After the integral hot-top casting platform is installed, evenly preheat the installed standard equipment platform to 260-350°C. Electric or gas baking can be used. No open flame can contact the product lining, otherwise the cracks will be damaged. The user undertakes to remove the adsorbed crystal water for safe and efficient use.

Process characteristics of hot top casting

1. Hot top casting is not only beneficial to improve the surface quality of the ingot, but also beneficial to the bottom-up directional solidification and supplementary shrinkage of the ingot. If the filter plate is added at the same time in the hot top section, it can prevent molten slag from entering the ingot in.

2. For a period of time after the aluminum liquid enters the copper crystallizer, the melt in the hot top can basically still maintain a higher temperature, which creates the floating of the precipitated gas during the solidification of the melt and the supplementary solidification shrinkage. good conditions.

Sorry, the comment form is closed at this time.