04 5月 Pug Tap Holes

Pug Tap Holes device prevents aluminum leakage

Pug Tap Holes makes the aluminum and aluminum alloy casting process more convenient, safer and more reliable. It is used for aluminum plugging in the casting furnace of the aluminum processing casting workshop. The material is high silica fiber and the refractory temperature is 1200 degrees.

In recent years, there have been explosions in aluminum plants.

The main reason is that the aluminum outlet is leaking aluminum and cannot be blocked in time.

?The furnace is filled with liquid aluminum, and once the aluminum leaks, the high-temperature aluminum liquid quickly leaks out, and people on the scene cannot get close to wherever they go.

Chinalco designed and developed an automatic leak plugging device with Pug Tap Holes.

In order to prevent aluminum leakage in the aluminum plant, reduce risks, and improve the level of automation and safety, the plugging system has a simple and compact structure, stable operation, convenient maintenance, and has strong practical value.

Many aluminum plants in China are equipped with automatic leak plugging devices to avoid aluminum leak accidents that cannot be blocked manually and to avoid major accidents.

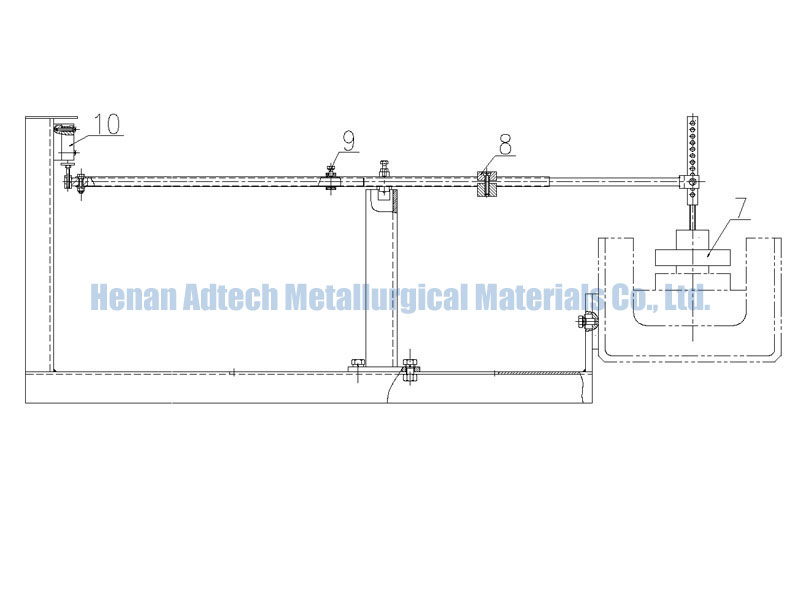

Structural features of Pug Tap Holes aluminum liquid plugging device

1. Select the appropriate hydraulic cylinder according to the thrust and stroke.

2. The hydraulic cylinder is fixed on the furnace body through the support. The front end of the hydraulic cylinder and the curved rod are fixed with a plug

3. The guide rail is fixed on the furnace body and has a built-in slider.

4. The hydraulic cylinder pushes the curved rod to move directionally on the guide rail, and then drives the plug to stop the leakage.

The whole system has a simple and compact structure, stable operation and convenient maintenance.

The driving device adopts hydraulic cylinder to ensure that the plug can effectively block the aluminum outlet.

Working principle of Pug Tap Holes plugging device

1. Use hydraulic drive to ensure that the plug has enough pressure to block the convection port. When aluminum leakage occurs at the aluminum outlet, the plugging device needs to be activated urgently.

2. Press the start button at the far end, then press the down button, the hydraulic station will open the overflow valve, increase the positive pressure, drive the hydraulic cylinder to extend, and drive the plug to plug the leak.

3. In the process of plugging down, the plug will be judged whether it is in place. After the blockage is in place, you will get a signal to close the overflow valve and the down solenoid valve. At this time, the plugging is successful and the plugging system stops running.

4. When there is no need to block, and the plug needs to be raised, press the start button, then press the down button, the hydraulic station will open the overflow valve, increase the negative pressure, make the hydraulic cylinder retract to the cylinder rod, and drive the crank rod and block Head up.

5. During the ascent process, the plugging device will continuously feed back the ascent signal. When the ascent signal is obtained, the hydraulic station closes the overflow valve and ascending solenoid valve. At this time, the lifting is successful and the plugging system stops running.

Sorry, the comment form is closed at this time.