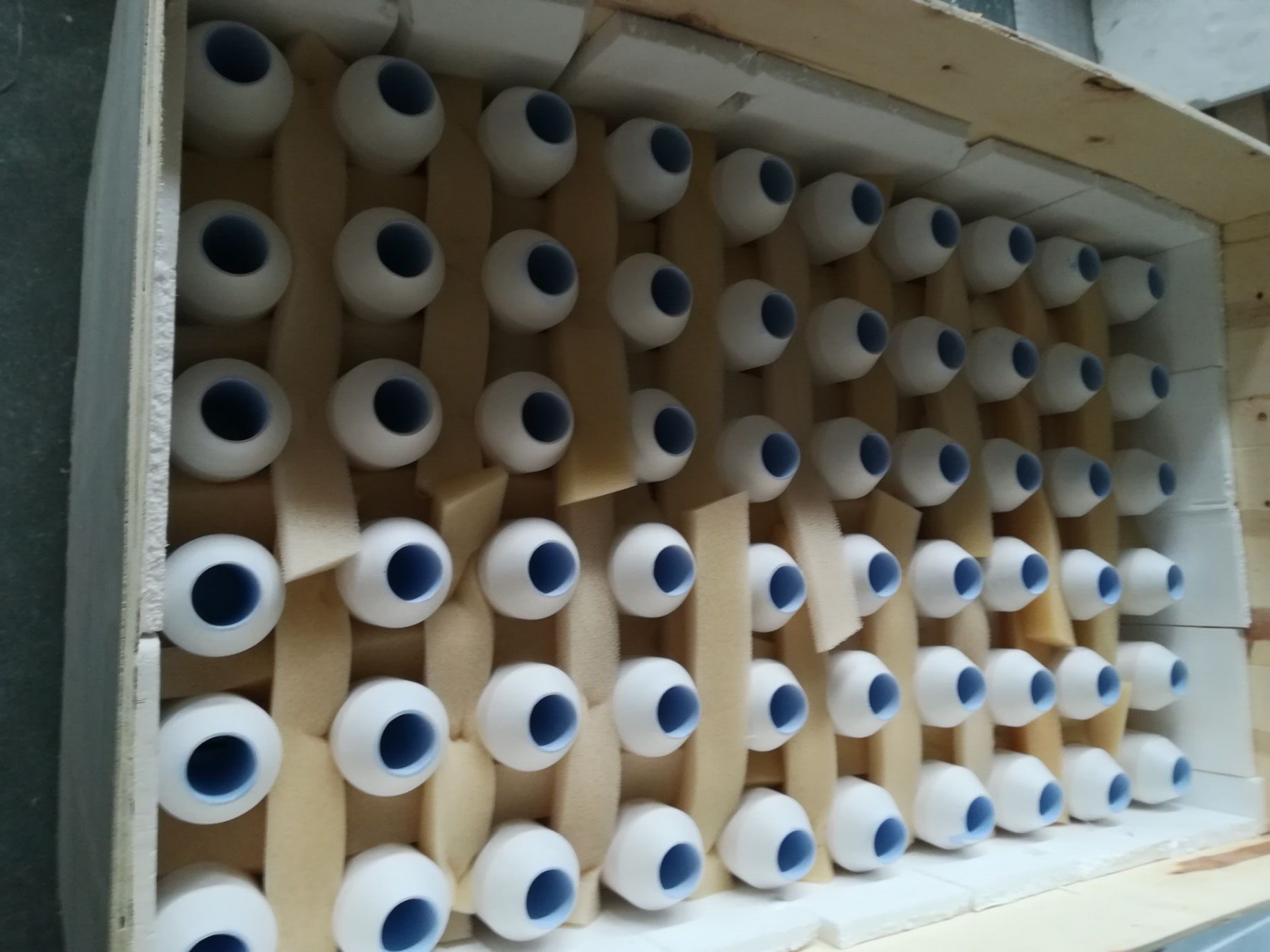

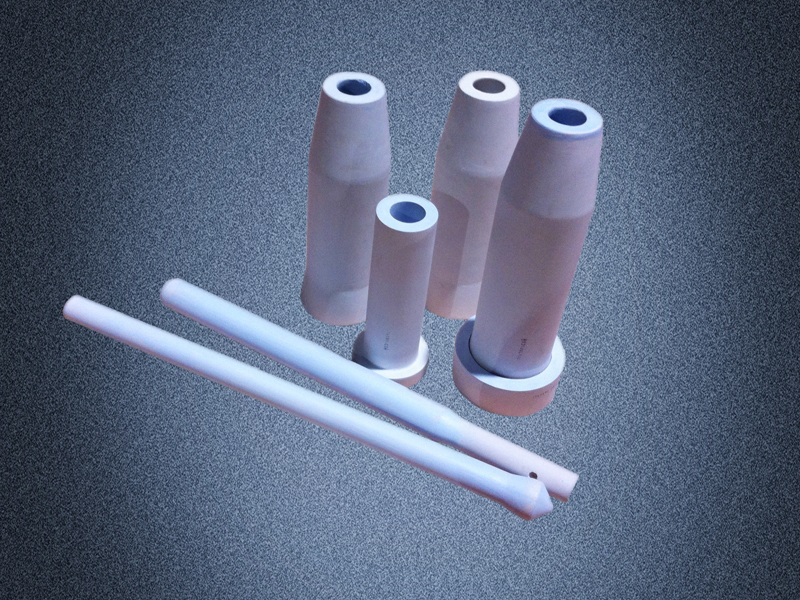

08 3月 China Ceramic Fiber Tap Out Cone Manufacturer

China Ceramic Fiber Tap Out Cone Manufacturer mixes high-purity aluminum silicate fiber with inorganic binder and vacuum-formed it. It is widely used in aluminum alloy smelting furnace to control the production flow of molten aluminum. Tap Out Cone For Aluminium Casting features 1. Aluminum tapping cone is...