20 11月 Molten Aluminum Purifier

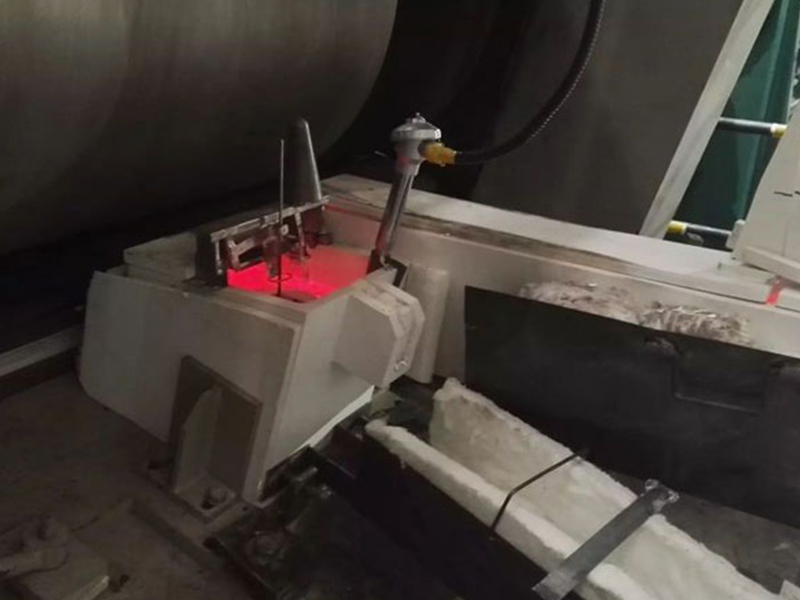

Molten Aluminum Purifier rotates at a high speed through a silicon nitride rotor, and sprays inert gases (argon and nitrogen) to make it evenly dispersed in the molten aluminum alloy liquid.

The diameter of inert bubbles will decrease, but the total surface area of the bubbles will increase dramatically.

Through more inert bubbles and extensive contact with hydrogen and impurities in the aluminum alloy liquid, the harmful substances of the aluminum alloy liquid can be brought to the surface of the molten liquid.

Buy Inline Degassing Machine through sales@adtechamm.com

The purification effect of the furnace refining treatment of aluminum alloy melt is limited, and the melt is prone to secondary pollution during the flow process, so it is difficult to control the impurities in the melt (hydrogen, alkaline metals, non-metallic inclusions).

Especially in the hot and rainy seasons in some countries, the pores and inclusions in the ingot seriously affect its internal quality, resulting in a decrease in the yield of aluminum products.

Molten Aluminum Purifier-processing box

The processing box includes two inner cavities, a clean room and a heating and holding room, separated by a SiC partition.

The bottoms of the two chambers are connected. After the aluminum alloy liquid is degassed and slag removed in the clean room, it flows into the insulation chamber from the bottom of the partition to stand for insulation.

The heat preservation room adopts a U-shaped silicon carbide protective tube that is immersed in an aluminum alloy liquid, and the heating box shell is made of 10 mm steel plate.

The inner lining is integrally cast with refractory materials. The upper part of the side wall is provided with an inspection and slag removal port, and the bottom is provided with a slag removal port.

Molten Aluminum Purifier-lifting system

In order to ensure its accurate positioning, two hydraulic cylinders are used as lifting devices to control the vertical up and down movement of the rotor and the heating system of the U-shaped silicon carbide heater.

It can rotate 90° horizontally, the hydraulic system is relatively stable, and the positioning is accurate.

Molten Aluminum Purifier-heating system

The heating system adopts an immersion heater, a U-shaped silicon carbide rod and a cylindrical silicon carbide or silicon nitride protective tube. There is a temperature measuring thermocouple in the tube, which can realize automatic temperature control, and the power can be adjusted arbitrarily within the range of 2 kW to 26 kW.

The temperature control system adopts a more advanced power integrated unit to realize automatic control, avoiding the shortcomings of lack of buffer stage when the heater is on and off. The U-shaped silicon carbide heater is constantly impacted by the main current during frequent on and off. In the non-buffer stage, the heater is easy to age and has a short life.

Sorry, the comment form is closed at this time.