05 5月 Molten Aluminum Launder

Molten Aluminum Launder

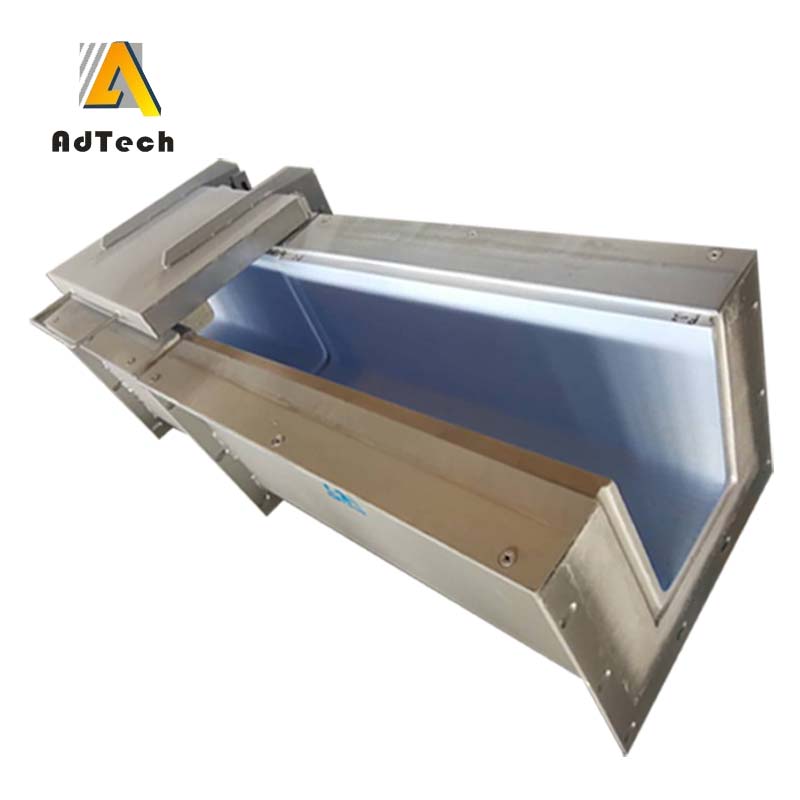

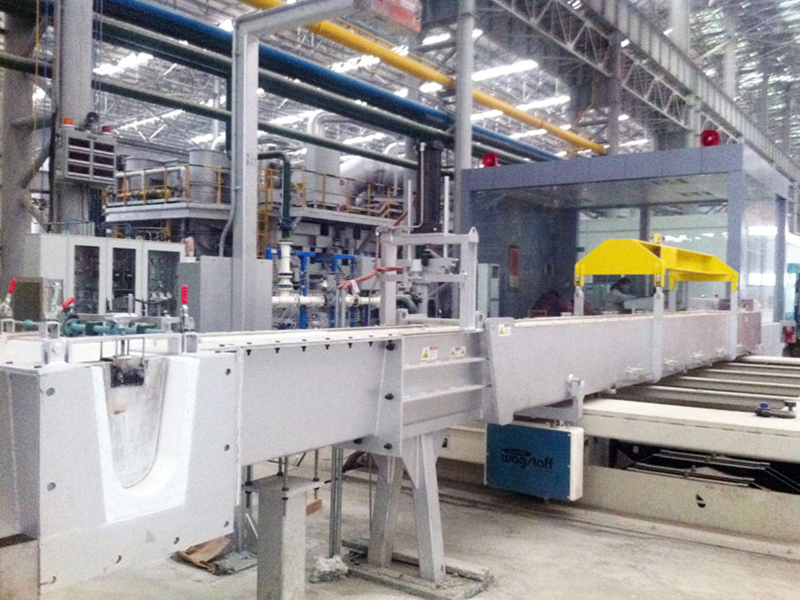

Molten Aluminum Launder is a key component in the production line of large aluminum alloy die castings. It is the channel to ensure the high temperature aluminum liquid enters the pressure chamber smoothly.

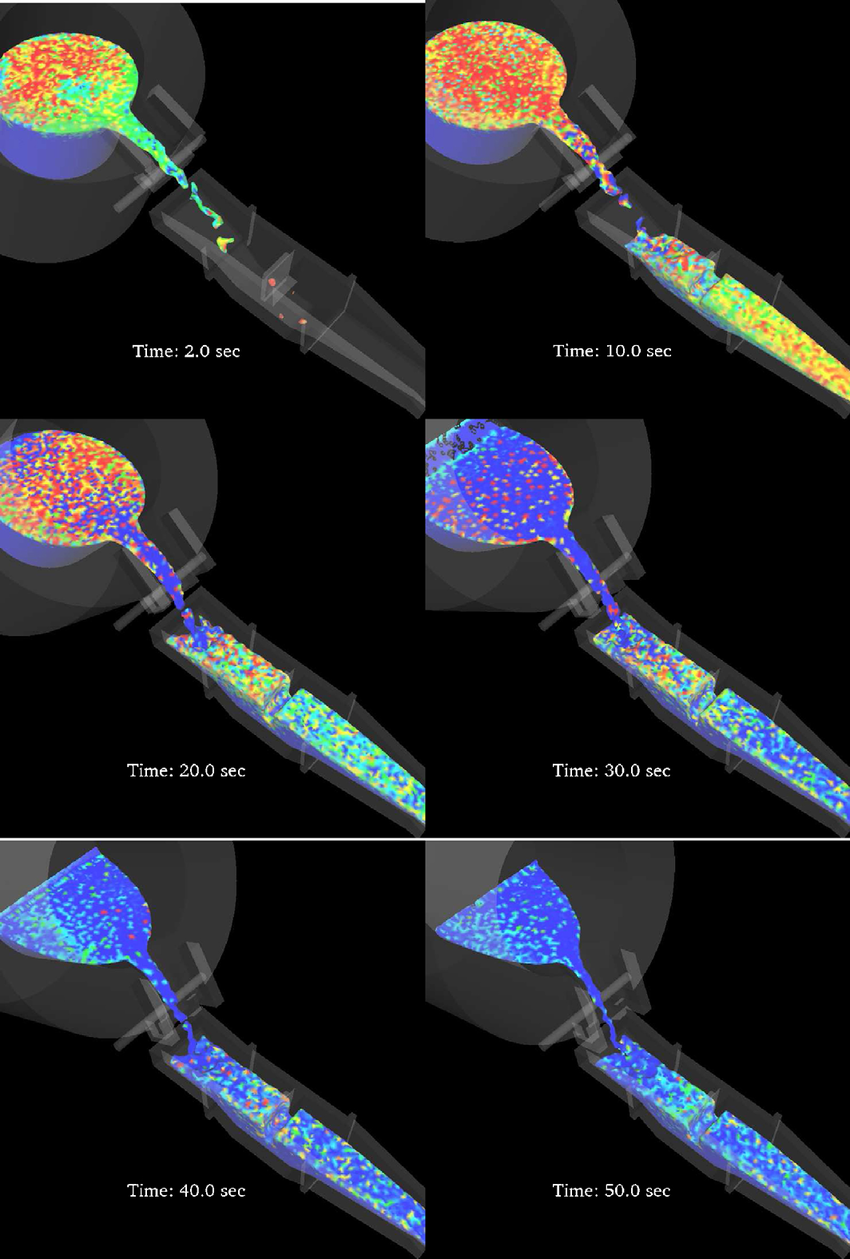

Molten Aluminum Launder often suffers from thermal fatigue cracking due to intermittent aluminum supply. The pouring temperature of aluminum liquid is about 680 °C. When high temperature aluminum liquid passes through the aluminum liquid flow tank, its working surface rises rapidly due to heat conduction temperature.

Since the wall thickness of the aluminum-launder is 4 mm 5 mm, there is a temperature gradient in the thickness direction of the runner, and the expansion of the material in the high temperature zone is limited, and compressive stress will be generated.

When the high temperature aluminum liquid passes through the Molten Aluminum Launder, the temperature of the working surface rapidly decreases, and there is still a temperature gradient in the thickness direction of the flow channel, which causes the deformation of the flow channel material to be inconsistent.

The shrinkage of the material in the low temperature zone is limited, and the tensile stress will be generated. The cyclic alternating stress will cause thermal fatigue cracks on the working surface, and as the number of thermal cycles increases, the crack will further expand, eventually causing the flow cell to crack and the aluminum liquid will not be smooth. Flow into the pressure chamber, so that the die casting process cannot be completed.

At the same time, there are two factors that accelerate the thermal fatigue damage of Molten Aluminum Launder. First, the oxidation of the launder is severe during use, the formation and shedding of the surface oxide scale, and the oxidation of the material on both sides of the crack and the tip material increases the brittleness of the material.

After the aluminum liquid infiltrated into the crack is solidified and oxidized, it is equivalent to embedding high hardness impurities in the material, thereby accelerating the crack propagation speed.

The breakage and destruction of Molten Aluminum Launder can seriously jeopardize the safety of production equipment and operators.

At present, the widely used protection method is to apply paint on the working surface of the aluminum liquid flow tank to prevent heat and corrosion. However, this paint is difficult to withstand the scouring of high-temperature aluminum liquid, and will quickly lose its protective effect.

Molten Aluminum Launder Advantages

1. The trough insulation performance is good, the design is reasonable, and the service life is prolonged.

2. The launder is integrally formed with noble molten material and has high dimensional accuracy.

3. The lining of the runner is strong, resistant to erosion, heat shock and smooth surface.

4. The lining of the runner is strong in corrosion resistance to aluminum, zinc and magnesium alloys, enhances the use effect of the molten metal transfer equipment, and strengthens the service life of special alloys.

5. The temperature drop of the metal liquid during the use of the launder is 2 °C per meter, resistant to erosion, heat shock and smooth surface.

Ceramic fiber type material series is a kind of white hard new insulation material. It has the characteristics of light weight, high strength, low thermal conductivity, high temperature resistance and corrosion resistance. It is widely used in metallurgy, chemical industry, machinery, military industry, Scientific research and other industries, also used in the aluminum and aluminum processing industries as molds or diversion slots, various industrial furnaces. Adtech can customize products according to user needs.

Sorry, the comment form is closed at this time.