29 10月 Molten Aluminium Metal Runner

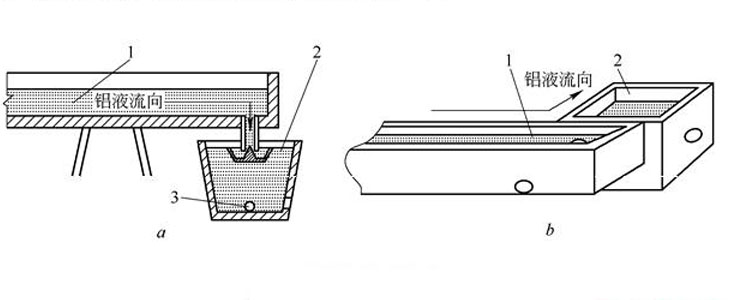

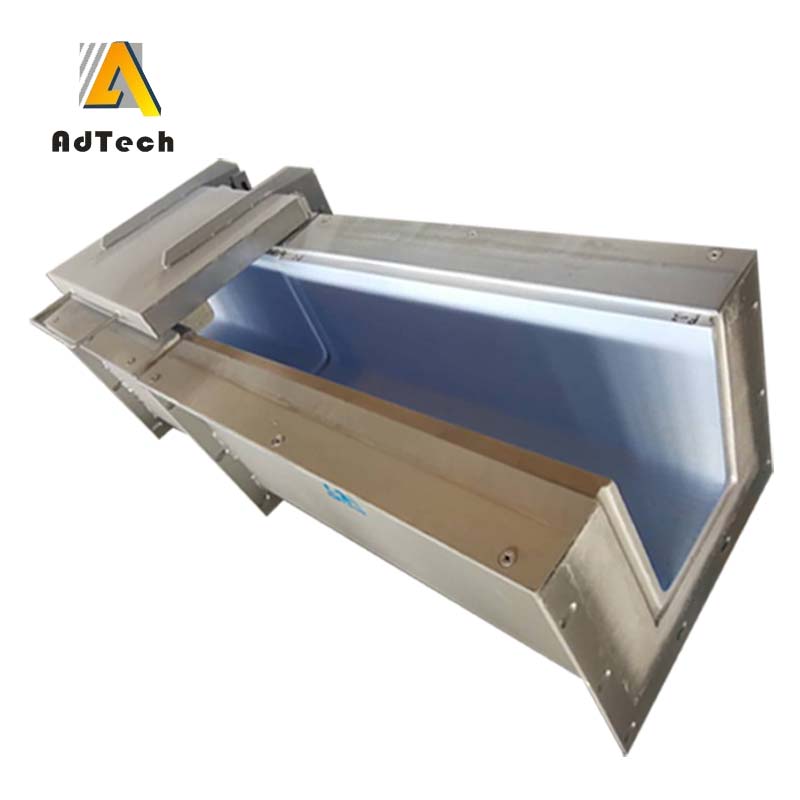

Molten Aluminium Metal Runner is the flow channel of molten aluminum from the static furnace to the front box. In order to avoid the heat dissipation of molten aluminum, the launder is required to have good thermal insulation.

When ensuring the length of the process, the length of the launder should be as short as possible, and it is best to be airtight, so as to prevent the melt temperature from dropping too much, and to avoid secondary pollution of the melt.

In order to facilitate maintenance, the launder is usually made of movable type, the outer shell is welded with steel plate, and the inner lining is made of aluminum silicate clay and asbestos thread.

In order to maintain the temperature of the molten aluminum, the aluminium launder can be covered with heat-preserving refractory materials, or a resistance wire or silicon carbide rod heating device can be installed on the launder.

Some factories also use gas flame nozzles to heat to ensure the temperature of the launder.

The relative position of Molten Aluminium Metal Runner and the front box is different, and the flow of aluminum liquid is also different.

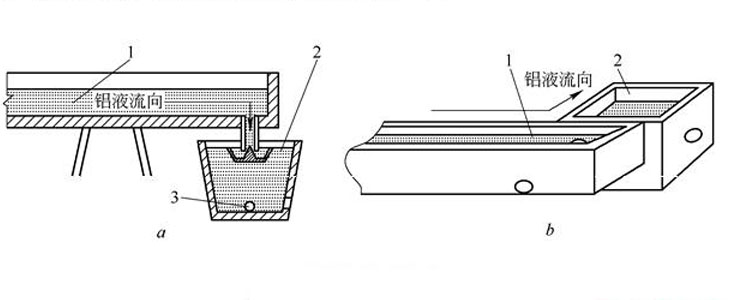

The vertical liquid aluminum supply method is shown in Figure a

This way of supplying liquid aluminum is from top to bottom, and the launder and the front box are at different levels.

This method is easy to control the liquid level of the front box, and the liquid level control device is relatively simple, but due to the drop in the process of the aluminum liquid flowing from the launder into the front box, the liquid level drops from the launder to the front box, which is easy to cause secondary absorption of the aluminum liquid. Gas slagging.

The side injection type aluminum liquid supply flow is shown in Figure b

The runner and the front box are on the same level.

This feeding method avoids the drop of the molten aluminum, because the center line of the launder is as high as the center line of the front box, and the center line of the furnace mouth of the standing furnace is lower than the center line of the rolling mill.

The oxide film formed on the surface of the molten aluminum acts as a protective layer. The molten aluminum is supplied under the oxide film in a submerged manner, which greatly reduces the phenomenon of suction and slagging during the flow of the molten aluminum.

However, the liquid level control device in this way is more complicated.

How to prevent the slag flushing trough from firing?

(1) Reasonably control the slag temperature.

(2) Reasonably control the height of the slag surface to prevent excessive instantaneous slag volume.

(3) Prevent the sticky slag from being brought out when slagging.

(4) Reasonably control the slag-iron-silicon ratio.

(5) Clean up a small amount of adhesion on the head of the hot slag chute in time.

(6) Carefully check whether the chute is deformed during the shift.

Sorry, the comment form is closed at this time.