18 6月 How Does A Degasser Work

How Does A Degasser Work?

The operation of the online degassing system must be carried out by skilled foundry workers, and non-casting operators must not operate at will.

Preparation before online degassing device

1. Check the mechanical system, electrical system and hydraulic system of the degassing device carefully before use, and deal with problems in time to ensure normal production.

2. Check the gas pipeline of the degassing device for leaks or blockage before use. If there is any problem, it should be treated in time to ensure the degassing effect.

3. Check carefully whether the rotor vent hole is unblocked, whether the graphite rotor rotates normally, and whether the gas flow is normal before casting.

4. Check whether the discharge ports are blocked before casting to prevent the aluminum melt from running.

5. Each white shift will open the upper cover of the deaerator and clean the slag and inspect the rotor. It must be replaced when the rotor head etches more than 50%.

6. Before each casting, clean the dust and other debris on the degassing device, clean all the aluminum scraps everywhere, and ensure the equipment is clean.

Degassing Tank Preheating

1. Check the wear of the refractory parts and repair parts of the container to prevent heat loss or metal leakage.

2, ceramic fiber cotton plugged in addition to the cylinder inlet and outlet.

3. The console heating program is set to preheat the cabinet and automatically control the heating.

Aluminum liquid handling operation

1. Set the temperature of the aluminum liquid according to the requirements. When the casting is ready, the temperature control table of the degassing box should be insulated at 730 °C. If there is no material in the degassing box for any reason such as alloy transfer or shutdown, it is necessary to ensure the filling of aluminum. The temperature inside the cabinet reaches 750 ° C and can be filled with aluminum.

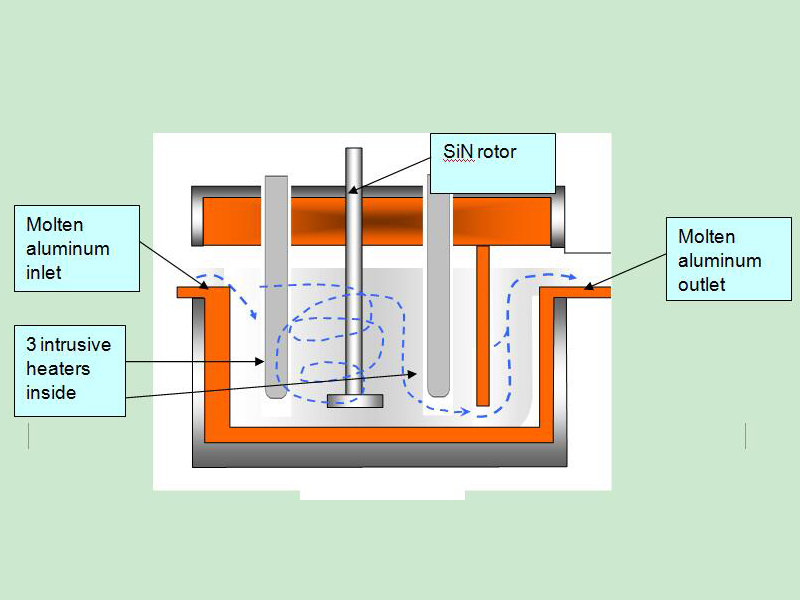

2. Before the furnace material enters the degassing box, the baffle in the front trough of the deaeration tank should be put down to properly raise the liquid level, so that the oxidation slag on the surface of the trough melt can enter the degassing chamber to float up, which is beneficial to be cleaned.

3. After the start of casting, the degassing gas is switched to argon gas, and the working state of the deaeration tank is set to the processing state.

4. Inject inert gas into the molten metal through the rotor, add chlorine gas to the inert gas, the flow rate of the inert gas is 4Nm3/h, and the flow rate of the chlorine gas is 0.5%-2% of the flow rate of the inert gas. Check the flow and pressure in the gas control cabinet, gas pressure The chlorine gas is 3 Bar and the argon gas is 6 Bar.

5. When the argon gas is suddenly unstable during the casting process, the rotation speed is reduced, or a certain rotor cannot work normally, it is decided to continue casting or returning to the furnace according to the measured hydrogen content on the line; if two or three rotors suddenly fail to work normally Must be processed immediately.

Replace the aluminum liquid in the deaerator

1. Check that the tools used for cleaning are dry and free of debris and have been brushed with refractory materials; otherwise they should be disposed of in time. Check that the aluminum slag tank is dry and free of debris, and check that the draining port is well connected to the aluminum discharging box.

2. Raise the rotor speed to above 200r/min for 3 minutes, remove the insulation cotton at the entrance and exit, and seal the upper cover of the empty box.

3. After the cover is fully lifted, the pin on the boom will be clamped for cleaning.

4. Use the steel wire or other items to clear the rotor air outlet to ensure that the shaft is in good working condition.

5. Clean the heater and the slag attached to the bottom of the upper cover, use a colander to remove the scum from the surface of the aluminum liquid, and check the wear of the inflatable seal and whether it is correctly located in the groove.

6. Ensure that there are no staff near the draining port and check that the draining bolts are good.

7. Open the drain port plug to ensure that the aluminum liquid flows smoothly into the aluminum discharge box. When releasing aluminum, use a long shovel to stir in the cylinder, and then clean the residual aluminum and slag in the drain after completion; check that the connection between the inlet and the cabinet is intact, and there is no sticky aluminum.

8. After emptying the aluminum liquid, clean the inner wall, bottom, and aluminum liquid inlet and outlet ports in time. The expansion seal, the box side wall and the middle baffle should not be damaged during the cleaning.

9. The inner wall of the degassing box and the aluminum inlet and outlet should be cleaned, free of residual aluminum and no residue. When the decontamination tank is cooled in the clearing, the crack is repaired with refractory mud, and the refractory mud should be smoothed as much as possible, then the bone powder water should be used. (1:3) Spray a layer evenly in the cylinder; if the inner wall of the cylinder is too rough, it needs to be coated with boron nitride water.

10. After completing the above work, after determining that there is no debris in the edge of the box and the seal, pull the boom pin out, drop the upper cover of the cylinder, and block the drain port and the aluminum port.

11. After the maintenance is completed, perform the preheating procedure of the cabinet to preheat.

12. Except that the cylinder is heated to above 730 °C, the aluminum liquid in the melting furnace can be introduced into the cylinder to ensure that the temperature of the aluminum liquid is not lower than 730 °C, and the temperature of the aluminum liquid cannot be higher or lower than the heater temperature to avoid heating. The device caused damage.

13. When the aluminum liquid is filled, a special person should be sent to observe the draining port.

14. Adjust the cylinder protection to the insulation state.

Degassing tank insulation operation

1. After the casting is finished, the state of the gas box is switched to the heat preservation state.

2. After entering the heat preservation state, the rotor speed is automatically converted to the set value.

3. Turn off nitrogen/argon.

4. Adjust the heater to low power.

Sorry, the comment form is closed at this time.