17 6月 How Degasser Works in the aluminium casting line

How Degasser Works in the aluminum casting line

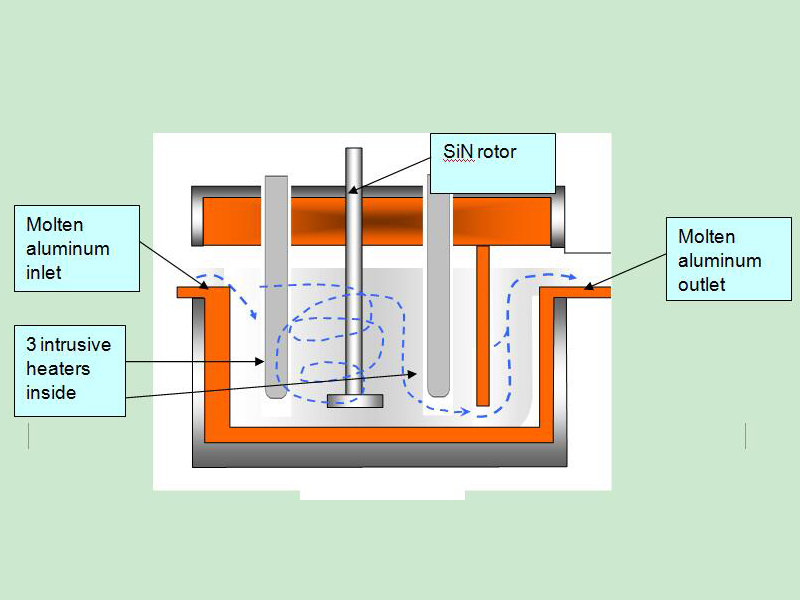

In the Degassing Process, the aluminum degassing unit breaks the inert gas (argon or nitrogen) blown into the aluminum liquid into a large number of dispersed bubbles through a rotating graphite rotor and disperses it in the aluminum liquid.

The bubble in the aluminum liquid depends on the gas partial pressure difference and the surface adsorption principle, absorbs the hydrogen in the aluminum liquid, adsorbs the oxidized slag, and is taken out of the surface of the aluminum liquid as the bubble rises so that the aluminum liquid can be purified.

Since the bubbles are finely dispersed, they are uniformly mixed with the rotating molten metal, and then spirally and slowly float upward, and the airflow generated by the continuous straight rise does not form when contacted with the aluminum liquid, thereby significantly improving the purification effect.

Nitrogen can be used as a gas for degassing and removing slag from aluminum liquid. The purity of nitrogen must be above 99.99%.

How does aluminum degasser work in the aluminium casting line?

The rotary degassing unit breaks up the Nitrogen large bubble into a very fine small bubble by rotating the Nitrogen rotor at a high speed and uniformly disperses it in the molten metal.

By reducing the diameter of the bubbles, the total surface area of these bubbles increases sharply, which causes more Nitrogen bubble surfaces to come into contact with hydrogen and impurities in the molten metal to bring these harmful substances to the surface of the liquid.

Aluminium casting line degassing unit instruction

Switch off the heating unit after degassing box heating is completed. Guide inert gas into the rotor and release molten aluminum into the box when the heater temperature is closed to molten aluminum temperature.

Check the sealing between inlet/outlet and launder.

Check the cone located in heat protection draining in the bottom.

Check the molten aluminum temperature (min 720°C). Make the height of molten aluminum be away from the launder bottom at 3cm for observing the molten aluminum going into the box.

An operator shall wear protection clothes to close the cover. The slag on the surface can be skimmed through the deslagging outlet when the molten aluminum flows into the box.

Start production when the temperature is up to 780°C. Close deslagging outlet for heating preservation.

Molten aluminum can be retained in the box with setting temperature during the heat preservation phase but with no molten aluminum handling.

Guide inert gases into the rotor to prevent air outlet blocking by molten aluminum.

Switch on the heater as soon as molten aluminum flow into the box is completed and set heat preservation parameters.

Starting the heating system, control the temperature of the molten aluminum, monitor the gas flow rate, and the speed of the rotor is changed from the heat preservation stage to the processing stage. At the same time, the inert gas flow into the rotor increases, and the gas flow rate is changed from the preservation stage to the processing stage.

The operator sets the molten aluminum heating temperature, and maintains a stable degassing working condition.

Sorry, the comment form is closed at this time.