10 7月 High Temperature Metal Aluminium Filtration Casting Filter

High Temperature Metal Aluminium Filtration Casting Filter

Casting Filter is available in a wide range of sizes and are suitable for use in all aluminum processing industries, such as electrolytic aluminum plants, strip processing plants, foil processing plants, tubular bar processing plants, and recycled aluminum ingot plants.

The quality of the aluminum melt is important, which greatly affects the subsequent processing properties and the quality of the final product. Therefore, all countries in the world are very fond of the purification of aluminum melt.

During the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag (such as furnace lining debris, chlorine in the flux). Compounds, carbides, etc.) as well as coarse intermetallic particles and the like.

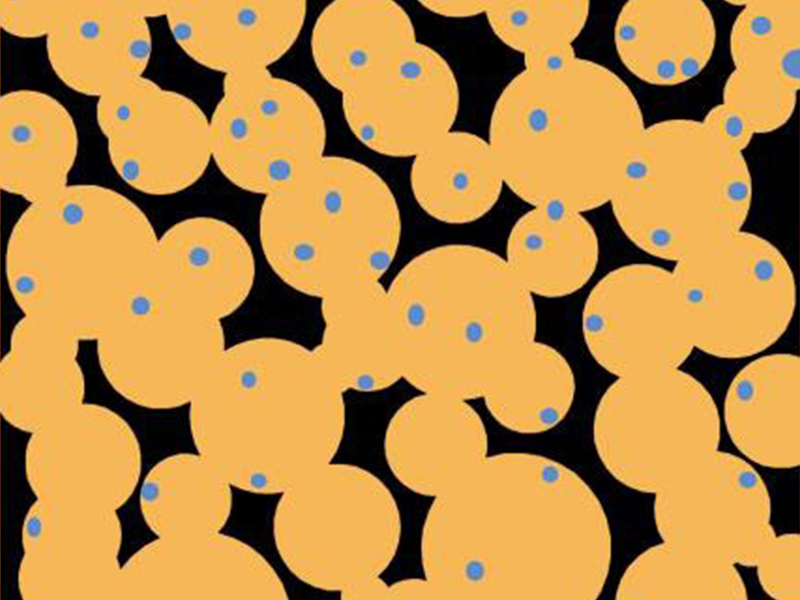

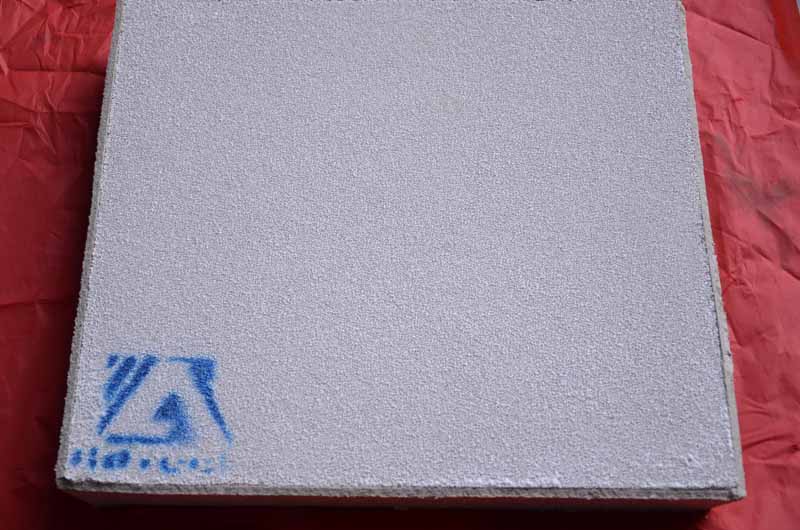

Aluminium Casting Filter adopts a three-dimensional network structure and an organic bubble connected to the pores as a carrier, invading it into the thixotropic alumina material slurry, and adopting a square-corrected center-distance automatic extrusion process to uniformly apply the slurry to the carrier. The foam body is formed by baking and solidifying at a high temperature of 1,180 °C.

Characteristics of Aluminium Casting Filter

Filtration technology has been used to remove inclusions in aluminum fluids for more than 30 years.

After successful use in production practice, it quickly replaced glass filter, microporous ceramic tube, alumina ball and other filter carriers.

Advantages for Ceramic Foam Filter

Adopt adsorption principle for filter, can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

No broken bits drop out, effectively reduce the pollution of molten aluminum.

Superior thermal shock resistance, improve erosion resistance ability of molten metal.

Automatic flow production,3 calibration procedures,precision size,fit the filter bowl tightly.

Improve the surface appearance and performance, purify molten aluminum.

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

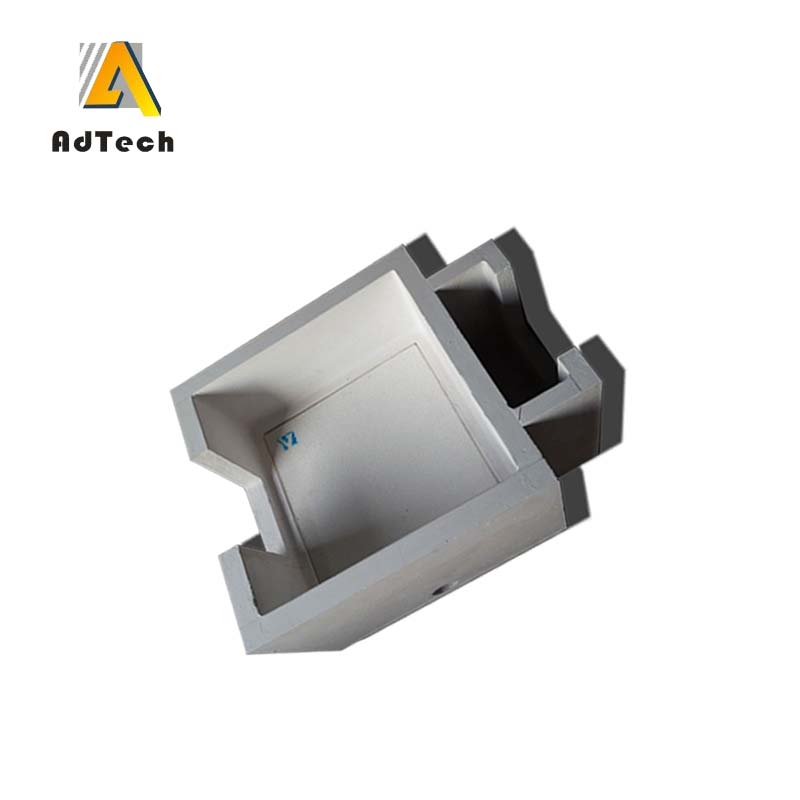

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM

Sorry, the comment form is closed at this time.