14 8月 High Ppi Foam Filter

High Ppi Foam Filter

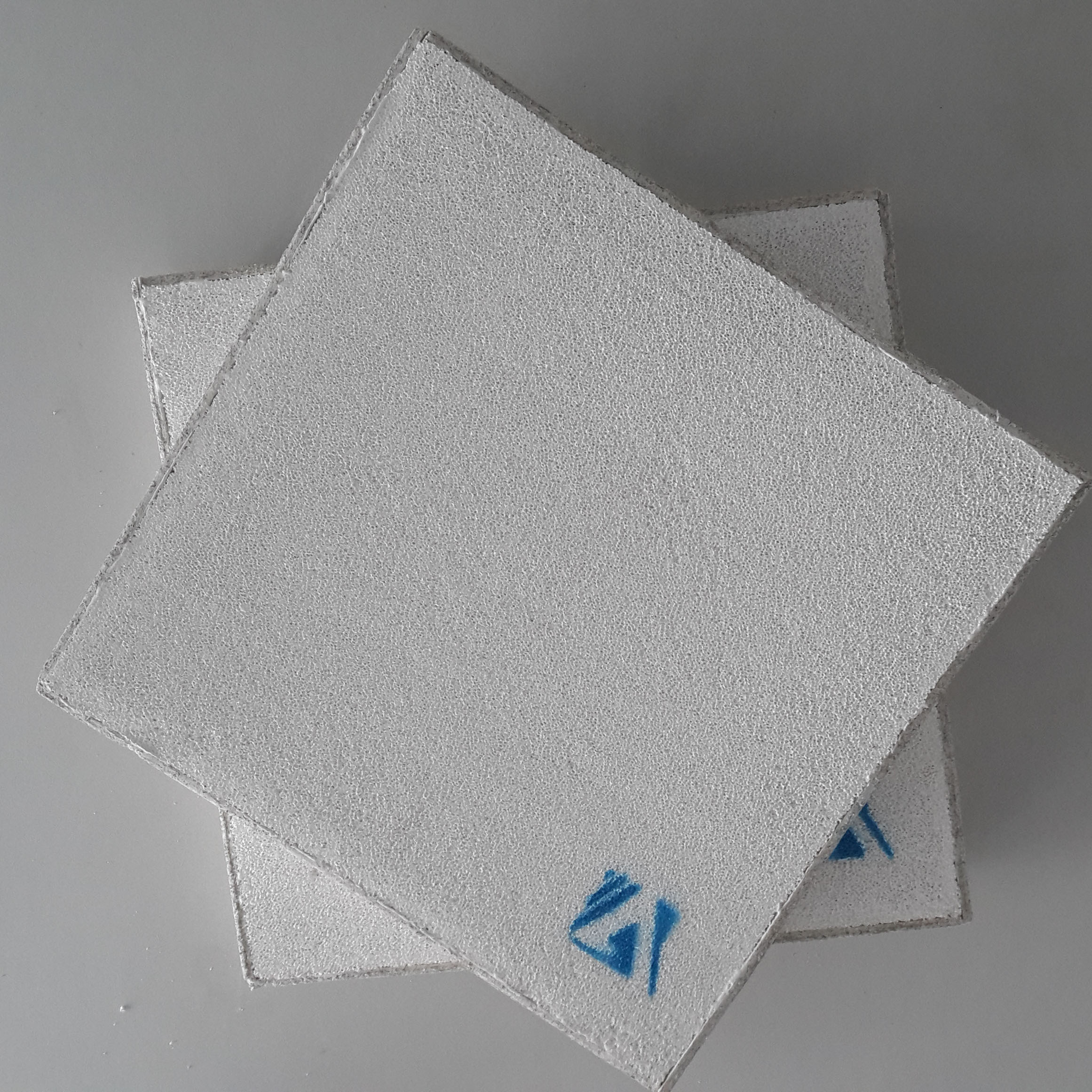

High Ppi Foam Filter is very cost-effective to filter out non-metallic solid inclusions in aluminum and aluminum alloy solution, and adopts foam sponge with high opening structure and high purity ceramic material.

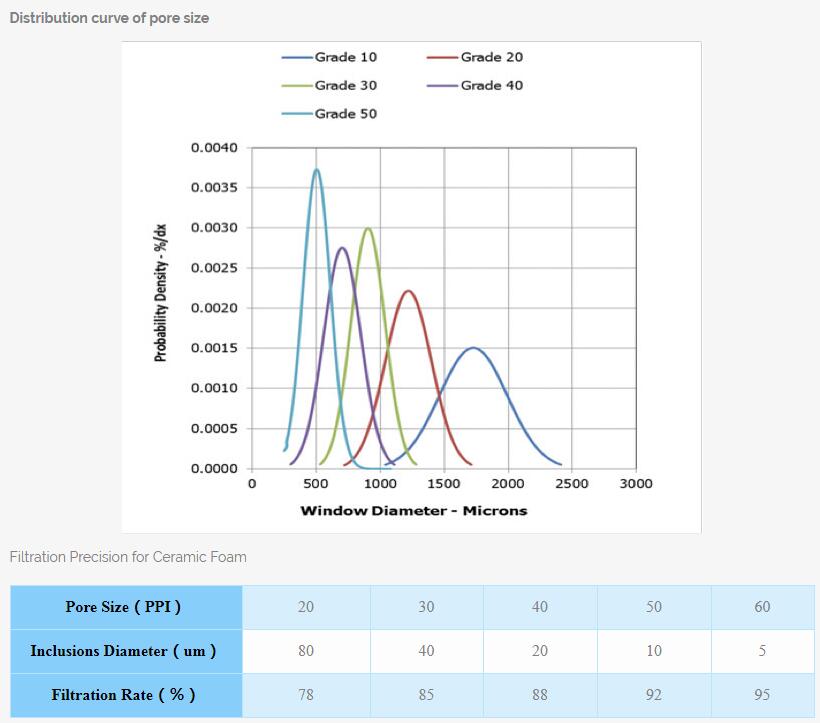

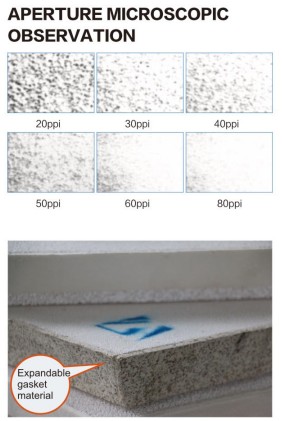

High Ppi Foam Filter manufactured under strict quality control has high pore diameter, high through-hole ratio, sufficient sintering, good flexural and compressive strength, and ensures high-efficiency filtration. The company has 10-45ppi foam with various pore sizes. Ceramic filter plates are available in a variety of sizes.

Foam ceramic filter plates are widely used in the filtration and purification of various aluminum and aluminum alloy solutions such as continuous casting, semi-continuous casting, gravity casting casting, and low-pressure casting casting. In addition to general specifications, it can be designed according to customer needs.

The production process of Foam ceramic filter

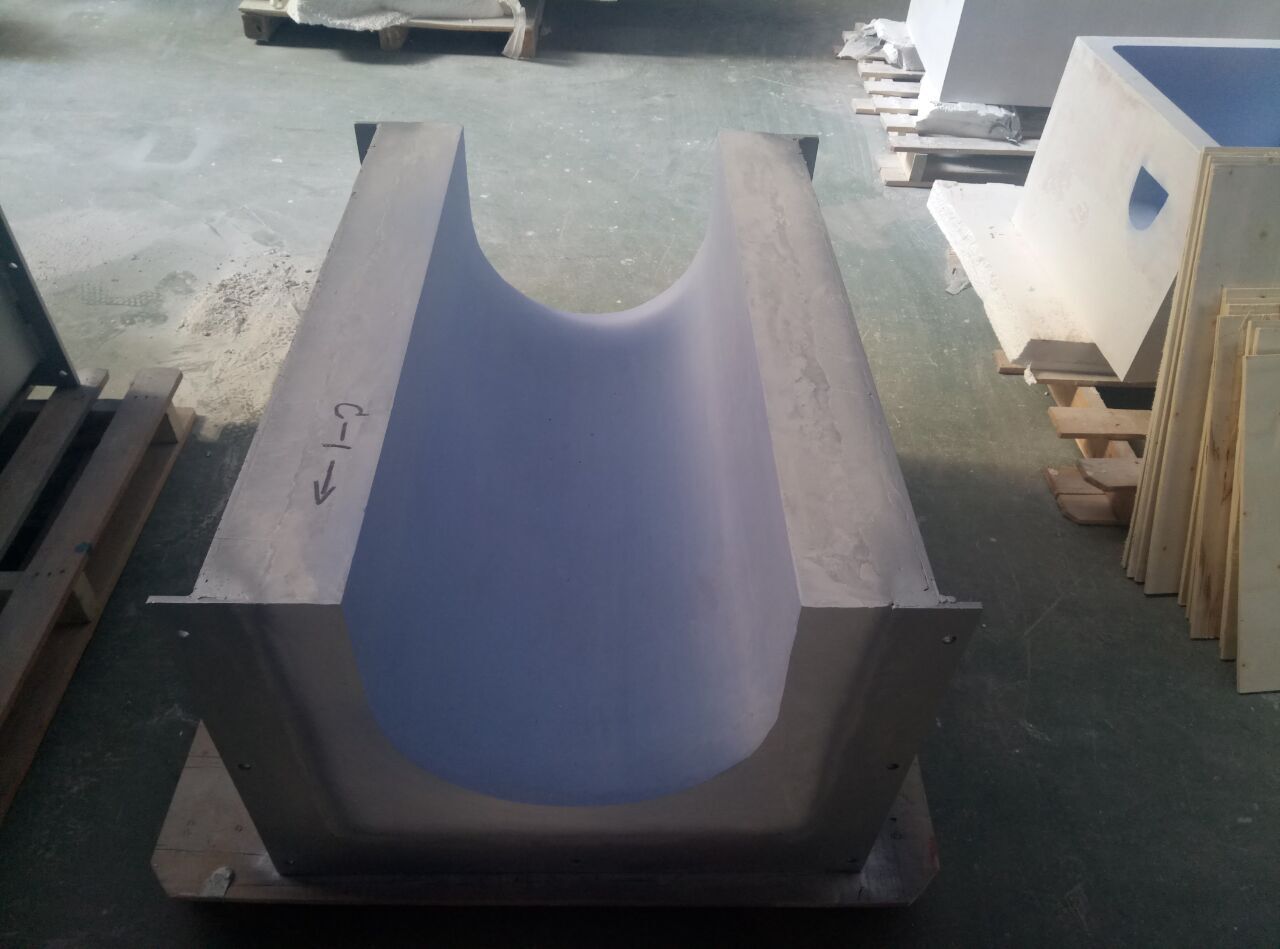

Alumina Molten Metal Filter use a three-dimensional network structure and a porous foamed organic foam as a carrier, invading it into a special ceramic slurry with thixotropic properties, and adopting a special roll extrusion process to uniformly apply the ceramic slurry to the skeleton of the carrier. Then, it is dried and solidified and then fired at a high temperature.

Aluminum plant ceramic filter plate, also known as foam ceramic filter plate, consists of alumina ceramic filter plate, silicon carbide ceramic filter plate and zirconia ceramic filter plate. Traits: three-dimensional network uniform skeletal structure, pink or white lumps.20 Ppi Filter Foam

High Ppi Foam Filter Features

It can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield. It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

High Ppi Foam Filter Instructions

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

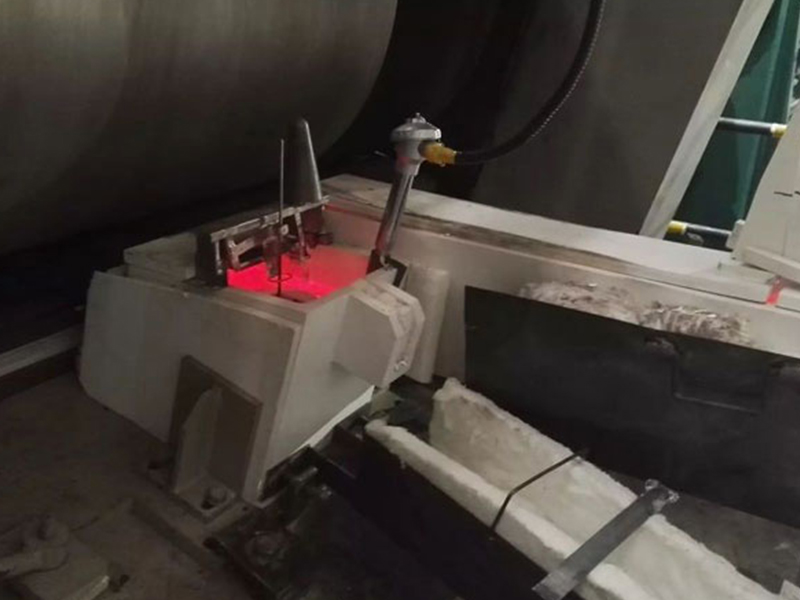

3. Evenly preheat the filter box and filter plate to bring it close to the temperature of the aluminum liquid. Preheat to remove moisture and facilitate initial transient filtration. Preheating can be carried out using electrical or gas heating. Under normal circumstances, it takes about 15–30 minutes.

4. Pay attention to the change of aluminum hydraulic head during casting. The normal starting pressure head is 100-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 75–100mm, and then the pressure head will slowly increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration is finished, remove the filter plate in time and clean the filter box.

Product specifications and models: This standard refers to the model number of the product, which is expressed by the current customary name P. The number in front of the English letter P represents the hole density of the product and corresponds to the pore uniformity. For example, model 10P, which means a foam ceramic filter product with a pore uniformity of 7 to 13 holes on any 25.4 mm length.

Aluminum and aluminum alloy production processes often use

178x178x50mm

230x230x50mm

305x305x50mm

381x381x50mm

432x432x50mm

508x508x50mm

584x584x50mm

A total of seven major specifications of ceramic foam filter products. Other specifications and models are required. Both supply and demand can be negotiated by both parties.

Dimensions and shape deviation: For the size and shape deviation of the foam ceramic filter plate, we mainly consider the influence of the use of the foam ceramic filter plate. The allowable deviation of the length of the diagonal line allows the deviation of the allowable deviation of the plane gap thickness. 5 indicators.

Sorry, the comment form is closed at this time.