18 6月 Grain Refining Aluminium Alloys

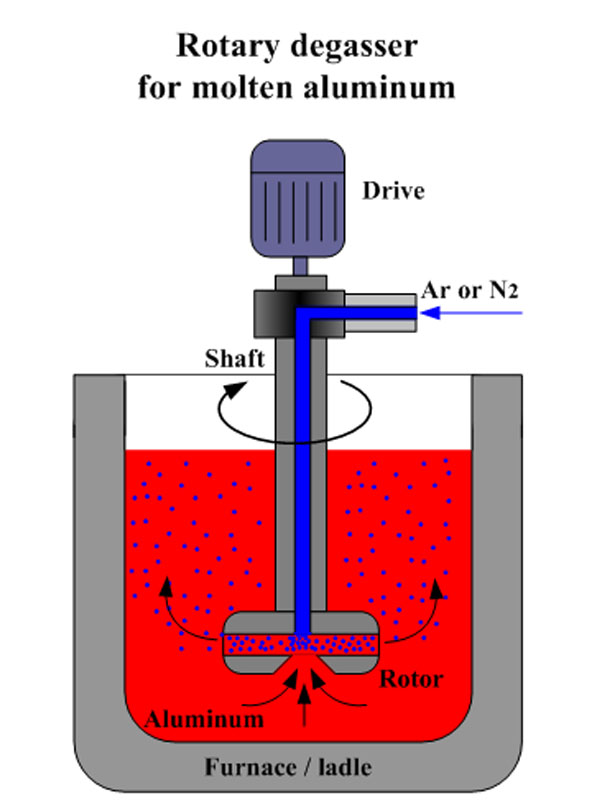

Grain Refining Aluminium Alloys is powdery particles, which are sprayed by a carrier gas (nitrogen or argon) to the bottom of the aluminum molten pool through a special refining powder sprayer, forming numerous bubbles in the aluminum liquid, and the bubbles move upward from the bottom.

During the floating process, it is fully contacted with the aluminum melt. Through the physical and chemical action, the gas and inclusions in the aluminum liquid are brought to the surface of the aluminum liquid to achieve the purpose of simultaneous degassing and slag removal.

After a lot of industrial trials, it has been proved that this type of refining agent has a significant effect on the degassing and slag removal of pure aluminum and aluminum alloys.

Grain Refining Aluminium Alloys adaptation range and dosage

1. General spraying agent: When the slag gas content is very high, the degassing and slag removing of non-high magnesium aluminum alloy and pure aluminum.

2. De-airing powder spraying agent: all aluminum alloys except high magnesium, mainly de-airing, which is used for the serious pollution of the furnace material. The gas content of the melt is higher, and the bubbles in the casting are the main quality.

Always the occasion.

3. Deslagging powder spraying agent: mainly used for removing slag, used in the melt of the crushed fine material with large surface area, high content of oxidized inclusions, mostly non-metallic inclusions in castings

Main quality problem occasions.

4. Refining and refining: both degassing and slag removal have the effect of refining, which is applied to aluminum alloys with pure aluminum and aluminum-silicon alloy less than 4%

5. Refining and modification: Al-Si alloy, degassing, slag removal and modification.

Features

The operation is simple and convenient, the labor intensity of workers is reduced, the utilization rate of Refining Agent is high, and the slag, degassing and purification of the solution are effectively achieved.

Precautions

1. Control the speed of powder feeding by turning on the size of the bottom switch of the refining tank, and try to have the flux sprayed out during the refining time.

2. Control the churn height of the aluminum liquid by controlling the nitrogen pressure. Under the premise of not blocking, the churn degree is better, preferably below 15cm.

Grain Refining Aluminium Alloys product advantages

1. Aluminum and aluminum alloy refining agents are powder particles, which have larger contact area with aluminum liquid than lump refining agents.

2. The degassing and slag removal effect is good. The refining sprayed to the bottom of the molten pool and the bottom of the furnace have a physical and chemical reaction, which can melt the alumina and separate the slag from the aluminum.

The gas is brought to the surface of the aluminum liquid, which keeps the bottom of the furnace clean, greatly reduces the number of furnace cleanings, improves the furnace utilization rate, and reduces the labor intensity

At the same time, the degassing separates oxides and impurities from the melt, and the resulting slag is dry and easy to separate from the metal, which improves the utilization rate of the metal and reduces the furnace on the furnace wall.

The adhesion of the slag facilitates furnace cleaning and maintenance and improves the working environment.

Manual powder refining tank

Powder spraying refining tank equipment~Auxiliary casting

Powder refining combines the advantages of traditional flux refining and gas refining, and the refining effect is much greater than the effects of the two single refining above; comprehensive consideration is given to flux and refining

The refining advantages of refining gas, through the refining gas as a medium to fully spray the flux into the melt to make the refining uniform and stable; simple operation process is easy to use

, Maintenance, and at the same time make up for many restrictions on site conditions.

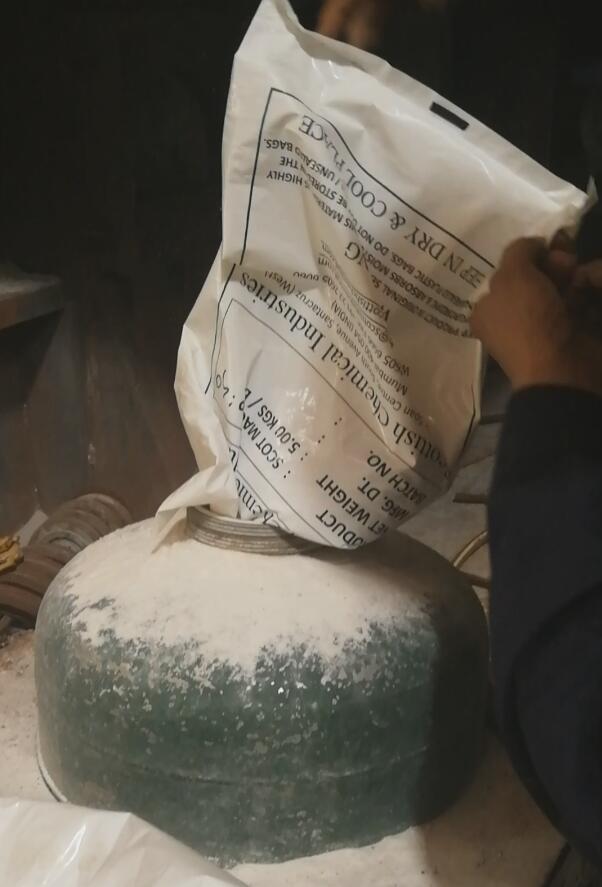

Powder Refining Instructions Place the required refining agent in the powder spray tank and compress the lid.

Turn on the gas pipeline switch, the gas to be refined is ejected from the refining tube, insert the refining tube into the melt for refining; the refining tube should be moved evenly during refining to make the melt

Complete refining; control the spray height of the melt by adjusting the pressure.

After refining, take out the refining tube and ventilate for another minute; turn off the gas.

Sorry, the comment form is closed at this time.