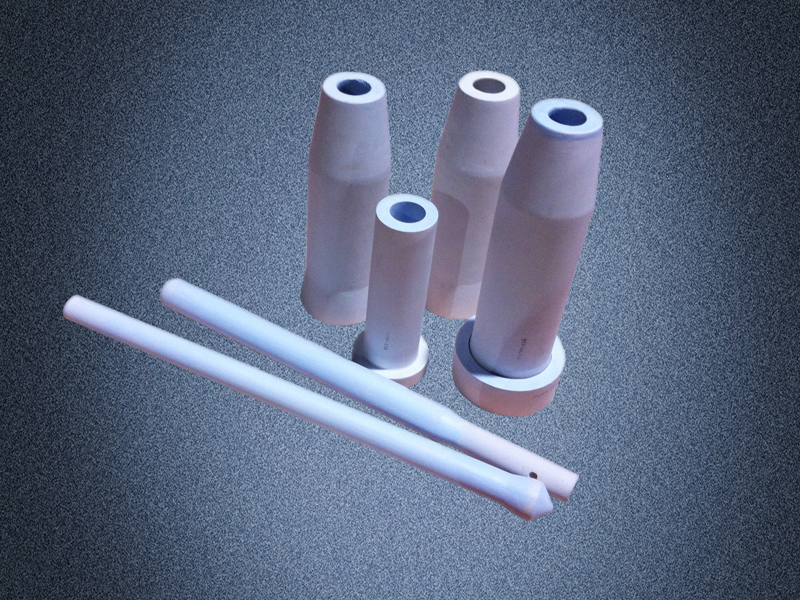

18 3月 Cubic Boron Nitride Coating

Cubic Boron Nitride Coating is sprayed on the surface of the mold that is in contact with hot or molten aluminum to avoid mold chemical attack and mold release, easier release, longer life of the mold / die, and greatly improve the surface cleanness of the product. Reduce production time.

How to use Cubic Boron Nitride Coating

Clean

Cubic Boron Nitride Coating is an inorganic high-temperature lubricating material, which is a coating that can be completely dissolved in water and has a wide range of uses.

The surface of the protected raw material must be cleaned before use, and this coating can only be used after rinsing.

In fact, each coating is used in the same way. Only the raw materials that have undergone surface treatment can be tightly combined with the coating. If there are too many foreign matter on it, the effect after painting must not reach people’s. Claim.

2. dilution

Boron Nitride coating can only be used after dilution.

Because when we buy this coating, when you open it, you will find that it is close to the solid shape and relatively viscous. It can only play an effective role after proper mixing and dilution.

Because this coating is divided into many kinds, if it is new aluminum launder, it will be diluted according to the ratio of 1: 4, if it is old aluminum lander, it will be diluted according to the ratio of 1: 6, or it can be based on your own You need to adjust the dilution ratio appropriately. After being diluted, choose the right tool and brush the paint on the surface.

3. drying

Because the Cubic Boron Nitride Coating itself is relatively special, it is also used on special raw materials. The surface of the material after brushing also needs special treatment, and high temperature drying is required.

In addition, there are certain requirements for the drying temperature. Generally, it is about 300 ° C. In addition, the coating must be uniform, and the surface must not have a lot of aggregates, and it cannot be applied too much.

thick.

Dry at the right temperature and wait until the coating is completely dry before using the raw materials.

Sorry, the comment form is closed at this time.