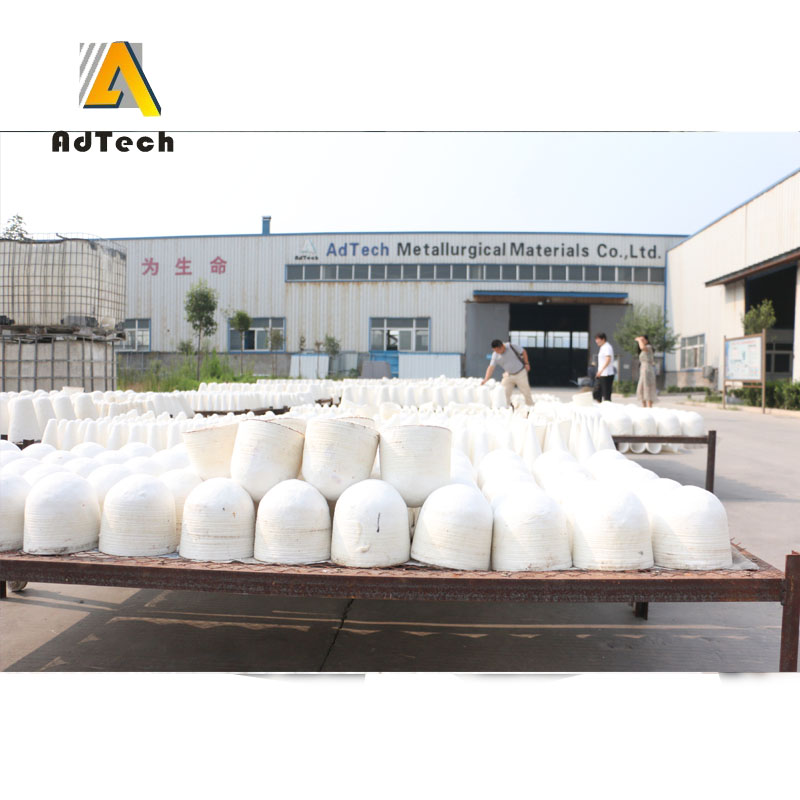

19 9月 Ceramic Fiber Cone

Ceramic Fiber Cone

MATERIALS FROM CERAMIC FIBER

Ceramic fibers based on aluminum silicate are obtained by melting a mixture of quartz with aluminum oxide at a temperature above 2000 ° C, followed by spraying the melt in a gas stream. With this method, standard amorphous or polycrystalline fibers are obtained, suitable for use at high temperatures of 1400-1600 ° C, but, unfortunately, spherical structures also occur in the mass of fibers, the presence of which reduces the mechanical and thermal insulation properties of the finished product. To give the obtained fibers the desired shapes and the necessary properties, an organic or inorganic binder is added to their mass, the products are made by vacuum pressing. From the raw materials obtained in this way, products such as: mats, plates, threads for the manufacture of textiles in various forms are produced.

Types and sizes of products.

There are two groups of ceramic fiber products. The first is products formed from non-oriented fibers, such as boards and mats. The second is products woven from threads and fibers, such as fabric cords, etc. The main standard products are presented in the table below, which describes the products that satisfy the needs of most regular customers and for which there is the highest demand in the market. Nevertheless, it is possible to supply non-standard products, upon presentation by the client of the specification with the required parameters.

The properties

Among the most important properties of ceramic fibers are worth noting:

stability at high temperatures and resistance to thermal shock.

low thermal conductivity and low heat storage coefficient.

rigidity and high density create the possibility of processing and cutting.

resistance to abrasion, contact with flame and chemical influences.

Application

thermal insulation of heating equipment;

pipeline insulation;

transport screens, covers;

insulation of buckets, mixers, storage boxes of thermal boxes of all types;

insulation of doors, dampers, technological windows;

insulating layers of air heaters, gas ducts;

use in the construction of buildings, boiler rooms, steam pipelines;

Benefits

effective thermal insulation at low density;

high thermal and fire resistance, resistance to thermal shock;

high chemical resistance;

products are elastic and fit tightly to the structures;

resistant to vibrations and deformations;

effective sound absorption;

durability;

effective thermal insulation at low density;

high thermal and fire resistance, resistance to thermal shock;

high chemical resistance;

insulation of curved surfaces (for large radii);

Main applications

Materials based on ceramic fiber are used primarily as a lightweight thermal insulation material at high temperatures and high demands on the stability of the insulation coating. The main customers for these materials are from the fields of energy, foundry, glass, and ceramic industries, and recently, the demand for such materials in mechanical engineering and the automotive industry has increased many times.

Adtech provides FLOW CONTROL SERIES

Seals for doors, shutters, technological windows;

Construction of boiler houses, buildings, ships;

Blacksmith furnaces;

Billet heating furnaces in metallurgy and mechanical engineering;

Catalysis furnaces, air heaters;

Furnaces for glass production, ceramics firing;

Heat generators, flues, chimneys;

Thermal compensation of dense refractories and concrete;

Lids of ladles, ladles of foundries, heating wells;

Soundproofing of heated equipment;

Steam lines;

Sorry, the comment form is closed at this time.